Method for preparing aniline through liquid phase hydrogenation of nitrobenzene with low phenol generation amount

A technology of nitrobenzene liquid and nitrobenzene is applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of high separation energy consumption, achieve simple process adjustment, reduce purification difficulty, impurity phenol low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

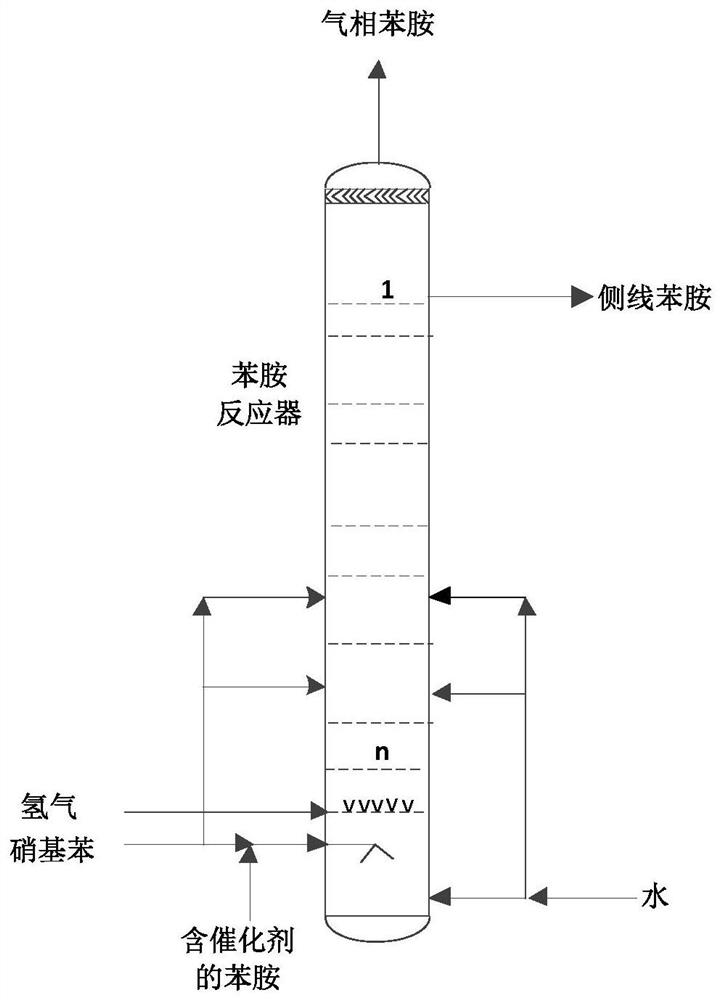

[0029] like figure 1 As shown, the aniline reactor adopts 30 trays. Mix the nitrobenzene with a flow rate of 16850kg / h at 135°C and the aniline solution with a flow rate of 18600kg / h at 90°C containing 2wt% catalyst and send it to the reactor of the reaction tower, and feed hydrogen at a flow rate of 1912kg / h at 72°C , with a flow rate of 10800kg / h, water at 40°C is used to control the temperature of the tower kettle to 69°C. The nitrobenzene with a flow rate of 10110kg / h and 135°C is passed into the 24th tray, and the feed flow rate is 14400kg / h, and the water at 40°C is used to control the temperature of the feed plate to be 183°C. The nitrobenzene with a flow rate of 6740kg / h and 135°C is passed into the 16th tray, the flow rate is 10800kg / h, and the temperature of the feed plate is controlled at 195°C by water at 40°C. During the reaction process, the pressure at the top of the tower was controlled at 17 bar, the temperature at the top of the tower was 218°C, the flow ra...

Embodiment 2

[0031] The aniline reactor uses 32 trays. Mix the nitrobenzene with a flow rate of 18600kg / h at 135°C and the aniline solution with a flow rate of 18600kg / h heated to 90°C containing 2wt% catalyst and send it to the reactor of the reaction tower, and feed hydrogen at a flow rate of 1912kg / h at 72°C , with a flow rate of 16200kg / h, 40 ℃ of water control tower kettle temperature is 66 ℃. The nitrobenzene with a flow rate of 7414kg / h and 135°C is passed into the 25th tray, and the feed flow rate is 7200kg / h, and the temperature of the feed plate is controlled at 188°C by water at 40°C. The nitrobenzene with a flow rate of 7751kg / h and 135°C is passed into the 15th tray, the feed flow rate is 12600kg / h, and the temperature of the feed plate is controlled at 193°C by water at 40°C. During the reaction process, the pressure at the top of the tower was 17 bar, the temperature at the top of the tower was 217°C, the flow rate of aniline in the side line was 14448 kg / h, and 75764 kg / h ...

Embodiment 3

[0033] The aniline reactor uses 28 trays. Mix the nitrobenzene with a flow rate of 13480kg / h at 135°C and the aniline solution containing 2wt% catalyst with a flow rate of 18600kg / h heated to 90°C and send it into the reactor of the reaction tower. Hydrogen, with a flow rate of 13680kg / h, 40 ℃ of water control tower kettle temperature is 65 ℃. The nitrobenzene with a flow rate of 11121kg / h and 135°C is passed into the 23rd tray, and the flow rate is 11880kg / h, and the water at 40°C is used to control the temperature of the feed plate to be 176°C. The nitrobenzene with a flow rate of 9099kg / h and 135°C is passed into the 15th tray, and the feed flow rate is 10440kg / h, and the water at 40°C is used to control the temperature of the feed plate to be 191°C. During the reaction process, the pressure at the top of the tower was controlled at 17 bar, the temperature at the top of the tower was 218°C, the flow rate of aniline in the side line was 13503 kg / h, and 76709 kg / h of crude a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com