Construction equipment for subway station deep foundation pit enclosure structure

A technology for enclosure structures and subway stations, which is used in infrastructure engineering, construction, excavation, etc., can solve the problems of danger, low effect, and large loss of lifting equipment, so as to increase service life, improve work efficiency, and reduce damage rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

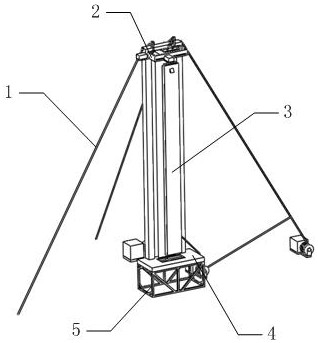

[0038] Such as figure 1 As shown, it includes a lifting mechanism 2, a rail frame 3, a base bracket 5, a base 4, and a pulling and fixing mechanism 1, wherein the base bracket 5 is detachably installed on the upper side of the ground, and the base 4 is detachably installed on the base bracket 5. The upper side of the base 4 is fixedly equipped with a guide rail frame 3, and the elevating mechanism 2 is slidably installed on the guide rail frame 3, and the guide rail frame 3 is equipped with a traction fixing mechanism 1.

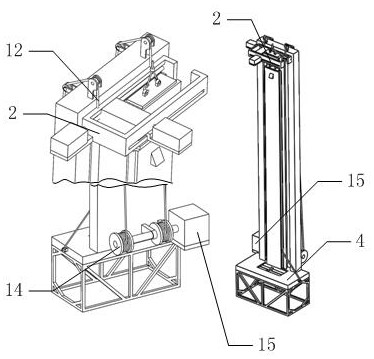

[0039] Such as Figure 10 , 11 As shown, the center of the above-mentioned base 4 has a square-shaped notch 50, and both sides of the notch 50 are pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap