Semi-automatic transmission auxiliary mechanism

A technology of semi-automatic transmissions and auxiliary mechanisms, which is applied to mechanical equipment, transmission devices, gear transmission devices, etc. It can solve the problems of short shift time, difficult clutch control, and long clutch separation and integration time, so as to reduce the power interruption of shifting Time, huge commercial application value, and the effect of improving smoothness of shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

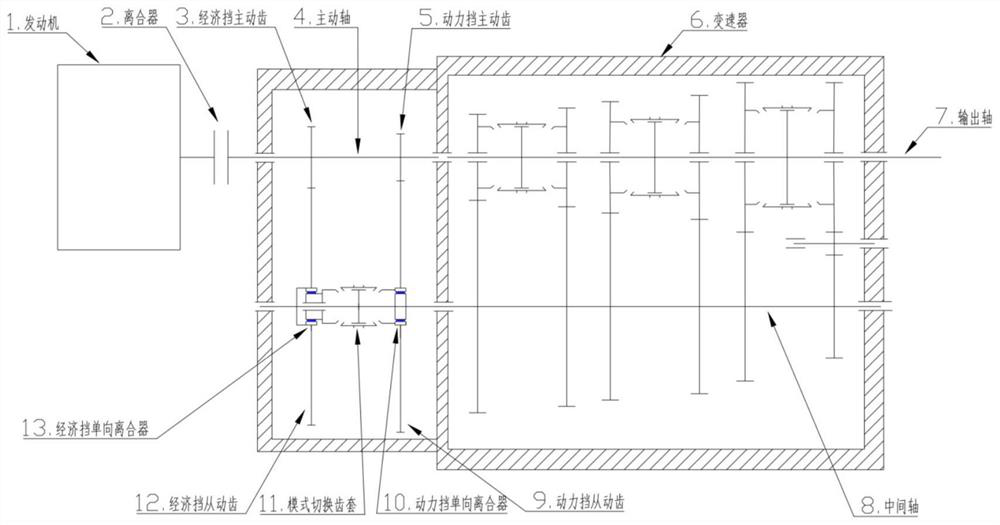

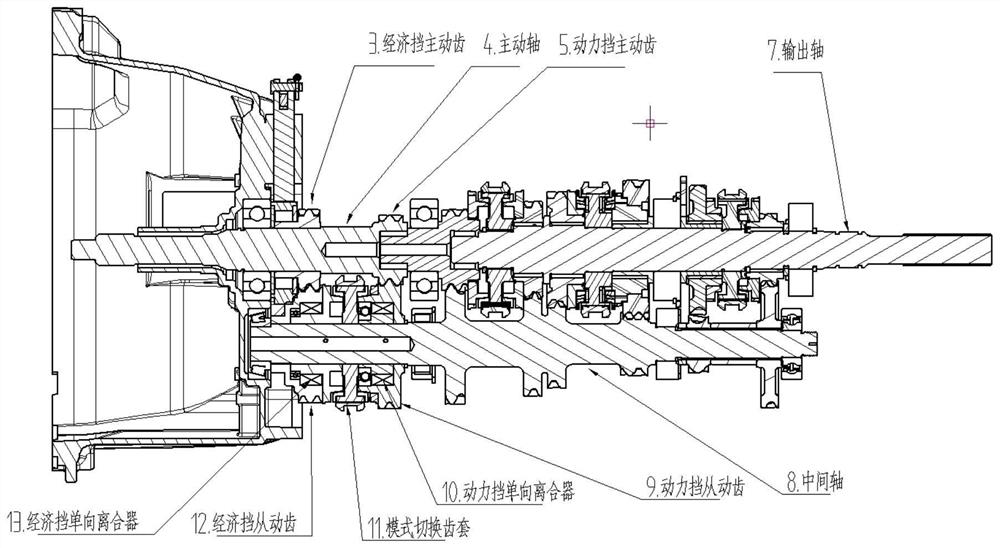

[0033] Such as figure 2 , including: economic gear driving gear 3, driving shaft 4, power gear driving gear 5, intermediate shaft 8, power gear driven gear 9, power gear one-way clutch 10, mode switching gear sleeve 11, economic gear driven gear 12, Economic gear one-way clutch 13.

[0034] In the power gear, the mode switching gear sleeve 11 is placed in the middle position, and the engine power passes through the clutch, the driving shaft 4, and the power gear driving gear 5, and is transmitted to the power gear driven gear 9 through the meshing of the gears, and then transmitted to the power gear unidirectional Clutch 10 Outer ring, the one-way clutch can realize that the outer ring drives the inner ring to rotate, but the inner ring cannot drive the outer ring to rotate. Through the function of the one-way clutch, the power is transmitted to the intermediate shaft 8, and then the engine power is transmitted to the transmission intermediate shaft 8 , to realize the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com