Sensor and method for measuring contact force of engine cam tappet

A technology of sensor and contact force, which is applied in the direction of engine testing, measurement of the property force of piezoelectric devices, and measuring devices, etc. The working space is narrow and other problems, to achieve the effect of simple structure, real measurement results and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

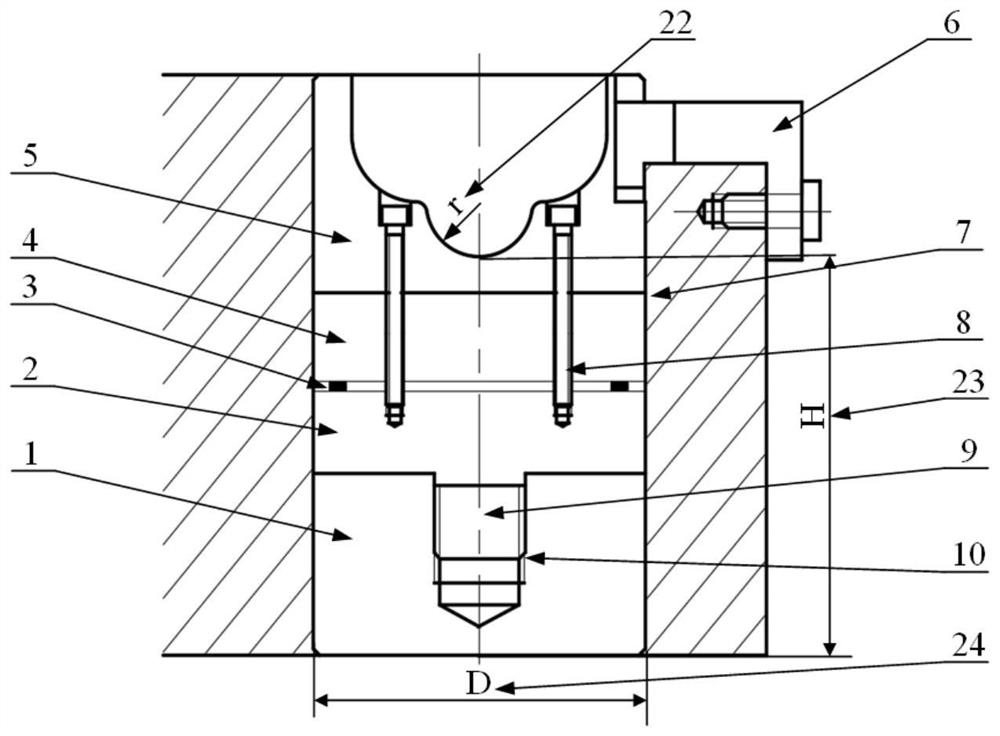

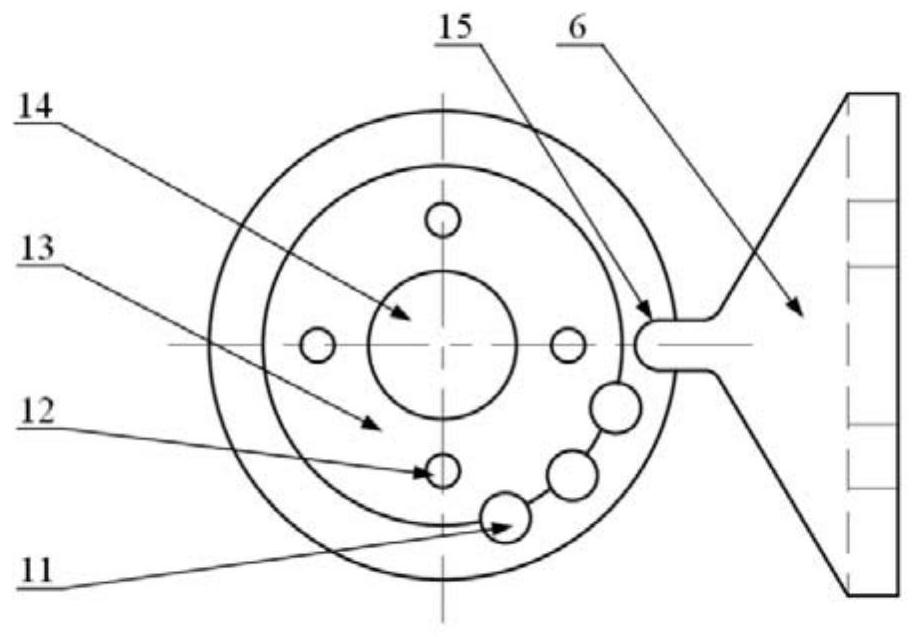

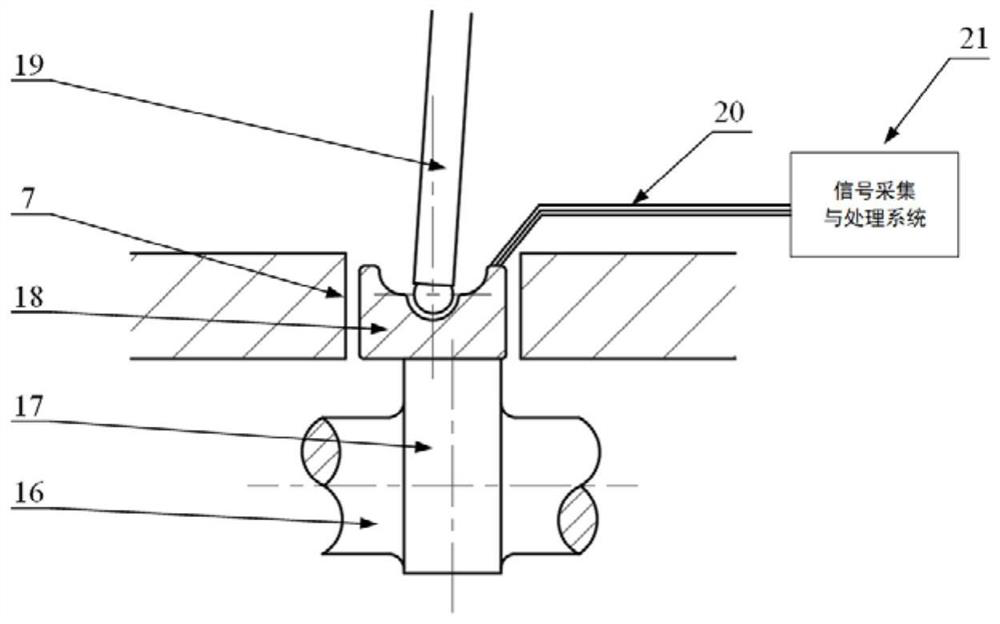

[0024] A sensor for measuring the contact force of an engine cam tappet, comprising: a force-bearing element, a force-transmitting element, a piezoelectric element, a load-bearing element, a tappet head, and a guide half-round key; one end surface of the force-bearing element has a force-transmitting Threaded hole; one end surface of the force transmission element has a force transmission bolt, the force transmission bolt cooperates with the force transmission threaded hole of the force bearing element, and four threaded holes are evenly spaced around the other end surface; the piezoelectric element is An annular sensitive element made of piezoelectric crystal; the load-bearing element has four through holes evenly spaced in the circumferential direction; the tappet head includes a large arc groove, a small hemispherical groove and thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com