Experimental device and method for rapid sample loading of metallurgical molten drops

An experimental device and experimental method technology, applied in the field of iron and steel metallurgy, can solve the problems of inaccurate experimental data, large errors, and poor repeatability of measurement samples, and achieve the effects of simple and fast steps, reduced impact, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention will be further described below with reference to the accompanying drawings.

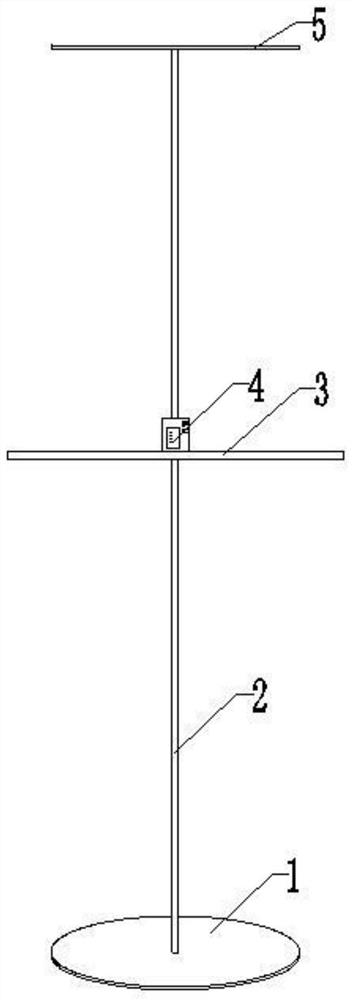

[0025] like figure 1 As shown in A of the present invention smelting financial fast dropwise experimental sample loading means comprises a platen 1, the support rod 2 and the measuring block 3, support rod 2 having one end connected to the central vertical platen 1, the measuring block 3 supporting rod sleeved 2, and is connected to the sliding support rod. Those skilled in the art will appreciate that the present apparatus includes a platen 1, the support rod 2 and the measuring block 3, the specific support bar 2 is connected to one end of a central vertical platen, and the platen 1 so that the support rod 2 vertically disposed, while preferably similar desired shape of the platen 1 experimental crucible shape. Measuring block 3 is mainly used for labeling and sample height / measuring sample height, and further the measuring block 3 is sleeved on the support rod 2, and is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com