Processing method of instant fish maw

A processing method and technology for fish maw, which are applied in food science, food heat treatment, fish cleaning/descaling, etc., can solve problems such as low fish maw content, and achieve the effects of increasing protein content, facilitating water injection, and avoiding protein loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

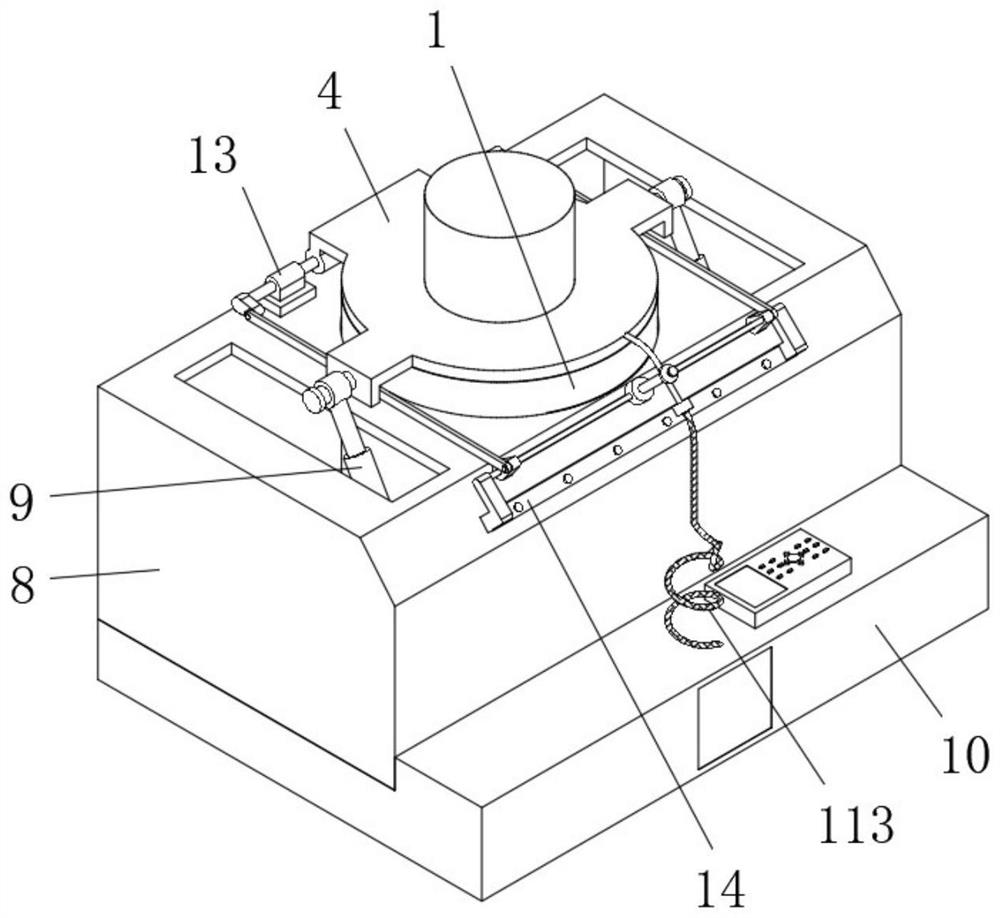

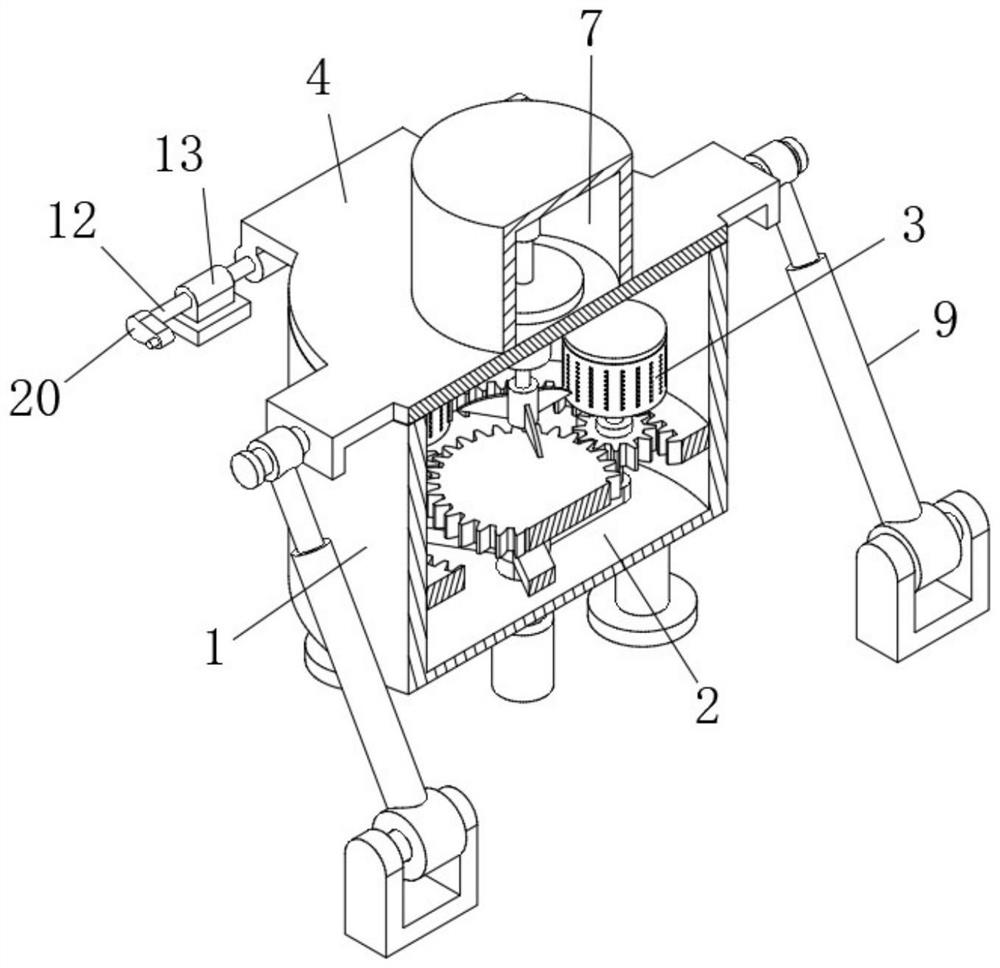

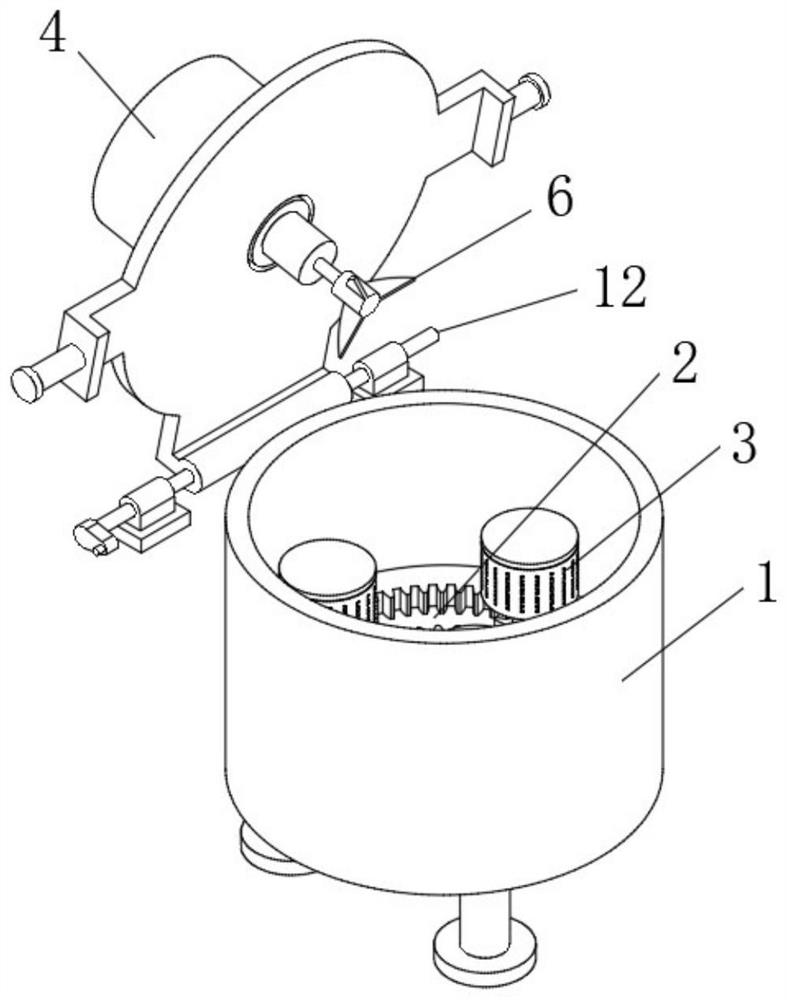

Image

Examples

Embodiment 1

[0041] The invention provides a processing method of instant fish maw, comprising the following steps:

[0042] S1: One-time soaking hair: take 60% of the dried fish maw and soak in cold water for 12 hours, then dry-steam the soaked fish maw for 40 minutes;

[0043] S2: Second soaking hair: Soak the fish maw in step S1 in cold water for 20 hours, change the water every 4 hours during this period, pick up the fish maw soaked in cold water and add it to 80°C hot water for soaking until hot water Cool to room temperature and remove the maw;

[0044] S3: cleaning the fish maw: washing the fish maw in a glue washer for 10 minutes;

[0045] S4: Soak hair three times: take out the gelatin in the washing machine and soak it in pure water, add 100g of ice cubes to the pure water every 3 hours;

[0046]S5: Filling: take out the fish gum in step S4, put it into the container after centrifugation, and add auxiliary materials to the container and vacuum seal;

[0047] S6: Sterilization:...

Embodiment 2

[0050] The invention provides a processing method of instant fish maw, comprising the following steps:

[0051] S1: One-time soaking hair: take 80% dried fish maw and soak in cold water for 12 hours, then dry-steam the soaked fish maw for 45 minutes;

[0052] S2: Second soaking hair: soak the fish maw in step S1 in cold water for 22 hours, change the water every 5 hours during this period, pick up the fish maw soaked in cold water and add it to 90°C hot water for soaking until hot water Cool to room temperature and remove the maw;

[0053] S3: cleaning the fish maw: washing the fish maw in a glue washer for 15 minutes;

[0054] S4: Soak hair three times: take out the gelatin in the washing machine and soak it in pure water, add 120g of ice cubes to the pure water every 3 hours;

[0055] S5: Filling: take out the fish gum in step S4, put it into the container after centrifugation, and add auxiliary materials to the container and vacuum seal;

[0056] S6: Sterilization: put t...

Embodiment 3

[0059] The invention provides a processing method of instant fish maw, comprising the following steps:

[0060] S1: Soak hair once: take 100g of dried fish maw and soak in cold water for 12 hours, then dry-steam the soaked fish maw for 50 minutes;

[0061] S2: Second soaking hair: Soak the fish maw in step S1 in cold water for 24 hours, change the water every 6 hours during this period, pick up the fish maw soaked in cold water and add it to 100°C hot water for soaking until hot water Cool to room temperature and remove the maw;

[0062] S3: cleaning the fish maw: washing the fish maw in a glue washer for 20 minutes;

[0063] S4: Soak hair three times: Take out the gelatin in the washing machine and soak it in pure water, add 150g of ice cubes to the pure water every 3 hours;

[0064] S5: Filling: take out the fish gum in step S4, put it into the container after centrifugation, and add auxiliary materials to the container and vacuum seal;

[0065] S6: Sterilization: put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com