High borosilicate glass cutting device and working method thereof

A high borosilicate glass and cutting device technology, applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems that the edge of high borosilicate glass is not parallel to the cutting direction, increase cutting loss, relative position error, etc., to achieve Wide applicability, reduced raw material consumption, and shortened adjustment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

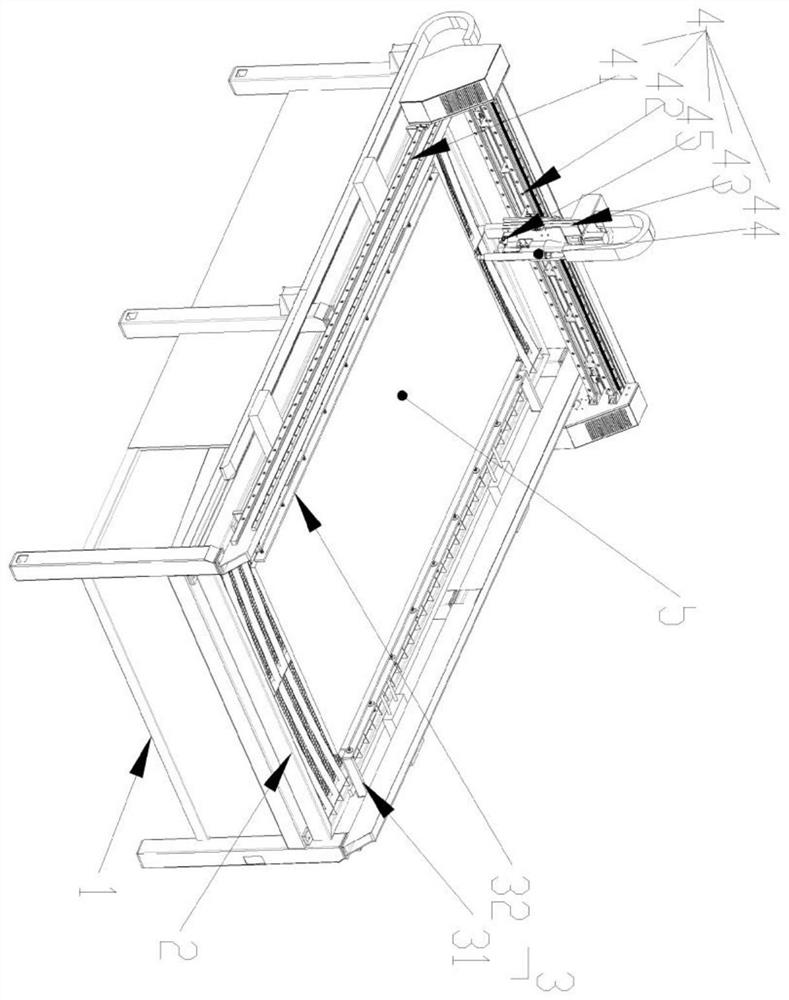

[0036] like figure 1 Shown is a perspective view of the present invention, including a frame 1, a cutting table structure 2, an automatic positioning structure 3, and a cutting structure assembly 4, the cutting table structure 2 is arranged on the frame 1, and the automatic positioning structure 3 Including a first limiting structure 31 and a second limiting structure 32, the first limiting structure 31 and the second limiting structure 32 are relatively arranged on both sides of the cutting table structure 2, and the cutting structure assembly 4 is arranged on The frame 1 is located above the cutting table structure 2 .

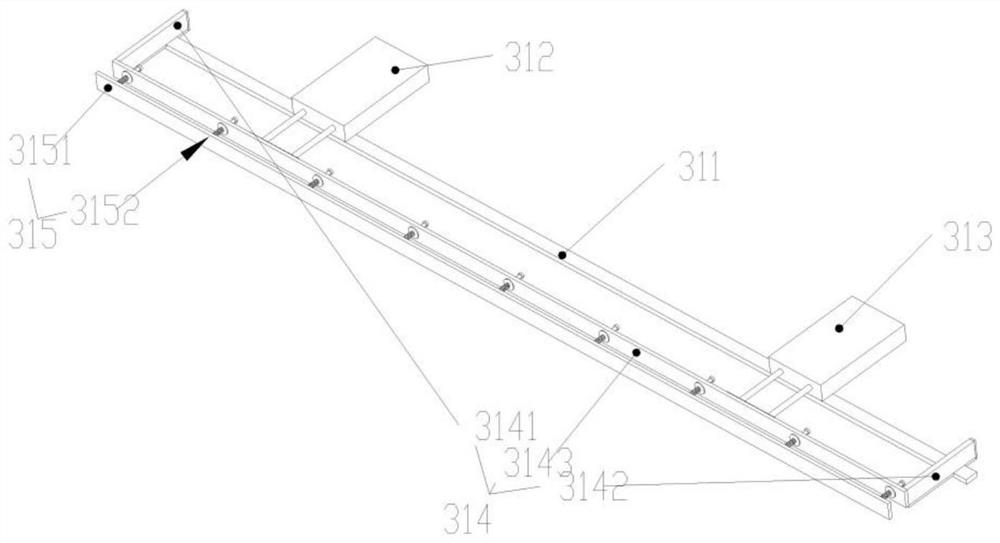

[0037] The first limiting structure 31 and the second limiting structure 32 have the same structure, as figure 2 Shown is a perspective view of the first limiting structure 31, including a limiting fixing plate 311, a first cylinder 312, a second cylinder 313, a limiting fixing frame structure 314, and a limiting and pressing structure 315. The first cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com