Efficient thermal-insulation ultralow-density polyurethane foam and preparation method thereof

A polyurethane foam and ultra-low density technology, applied in the field of ultra-low density polyurethane foam, can solve the problems of high foaming material waste rate, low production safety, and non-environmental foaming agent, so as to reduce molding density and flow Good performance, reduce the effect of heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

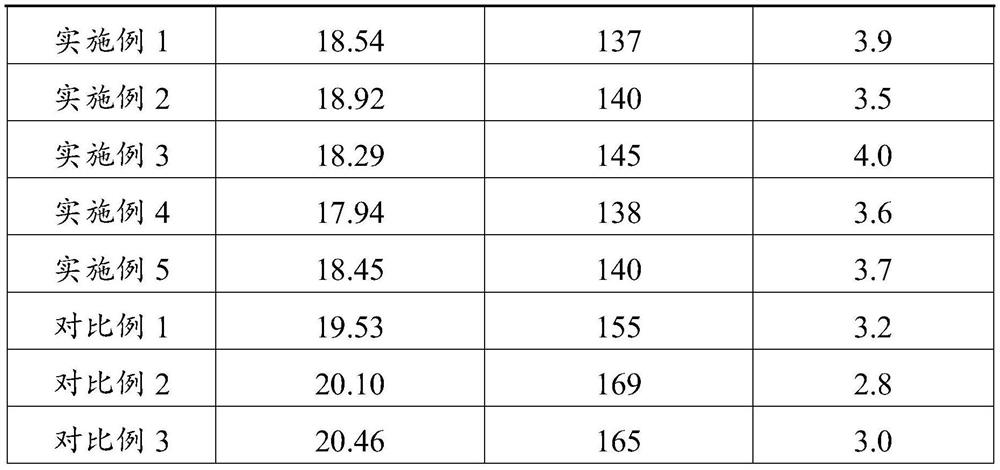

Examples

Embodiment 1

[0025] Embodiment 1: a kind of high-efficiency thermal insulation ultra-low-density polyurethane foam is prepared from the following raw materials in parts by weight: 100 parts of polyether polyol (25 parts of polyether polyol A, 45 parts of polyether polyol B, polyether polyol B, 5 parts of ether polyol C, 15 parts of polyether polyol D, 10 parts of polyether polyol E); 50 parts of polyester polyol (25 parts of modified polyester polyol, 25 parts of aromatic polyester polyol); flake graphite 15 parts (the particle size of flake graphite is 1000); 13 parts of water; 1.0 parts of curing agent; Oxy-bisbenzenesulfonyl hydrazide); emulsifier, wherein the quality of the emulsifier is 1.30 compared to the total mass of other raw materials, and the emulsifier is polysiloxane.

Embodiment 2

[0026] Embodiment 2: a kind of high-efficiency thermal insulation ultra-low density polyurethane foam is prepared from the following raw materials in parts by weight: 100 parts of polyether polyol (35 parts of polyether polyol A, 30 parts of polyether polyol B, polyether polyol B, 15 parts of ether polyol C, 15 parts of polyether polyol D, 5 parts of polyether polyol E); 50 parts of polyester polyol (50 parts of modified polyester polyol); 10 parts of flake graphite (grain of flake graphite diameter is 7000); 20 parts of water; 3.5 parts of curing agent; 1.0 parts of foaming agent (foaming agent is 3-3'-disulfonyl hydrazide diphenyl sulfone); emulsifier, wherein the quality of emulsifier is the total mass of other raw materials The ratio is 1.20, and the emulsifier is polyoxyethylene ether.

Embodiment 3

[0027] Embodiment 3: a kind of high-efficiency thermal insulation ultra-low density polyurethane foam is prepared from the following raw materials in parts by weight: 100 parts of polyether polyol (20 parts of polyether polyol A, 40 parts of polyether polyol B, polyether polyol B, 20 parts of ether polyol C, 15 parts of polyether polyol D, 5 parts of polyether polyol E); 50 parts of polyester polyol (50 parts of aromatic polyester polyol); 20 parts of flake graphite (the Particle size is 3000); 15 parts of water; 2.5 parts of curing agent; 4.0 parts of foaming agent (foaming agent is 4-4'-oxobisbenzenesulfonyl hydrazide); emulsifier, wherein the quality of emulsifier other raw materials are total The mass ratio is 1.25, and the emulsifier is polyoxypropylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com