Combined weft yarn spray pipe and manufacturing method thereof

A manufacturing method and combined technology, which is applied in the direction of material gluing, textiles and papermaking, looms, etc., can solve the problems of not being able to adapt to the transformation of air-jet looms, affecting the weft yarn handling force, and low processing efficiency, so as to achieve bonding effect and Good sealing, easy to popularize and use, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0026] The left-right direction described in the present invention refers to figure 1 in the left-right direction.

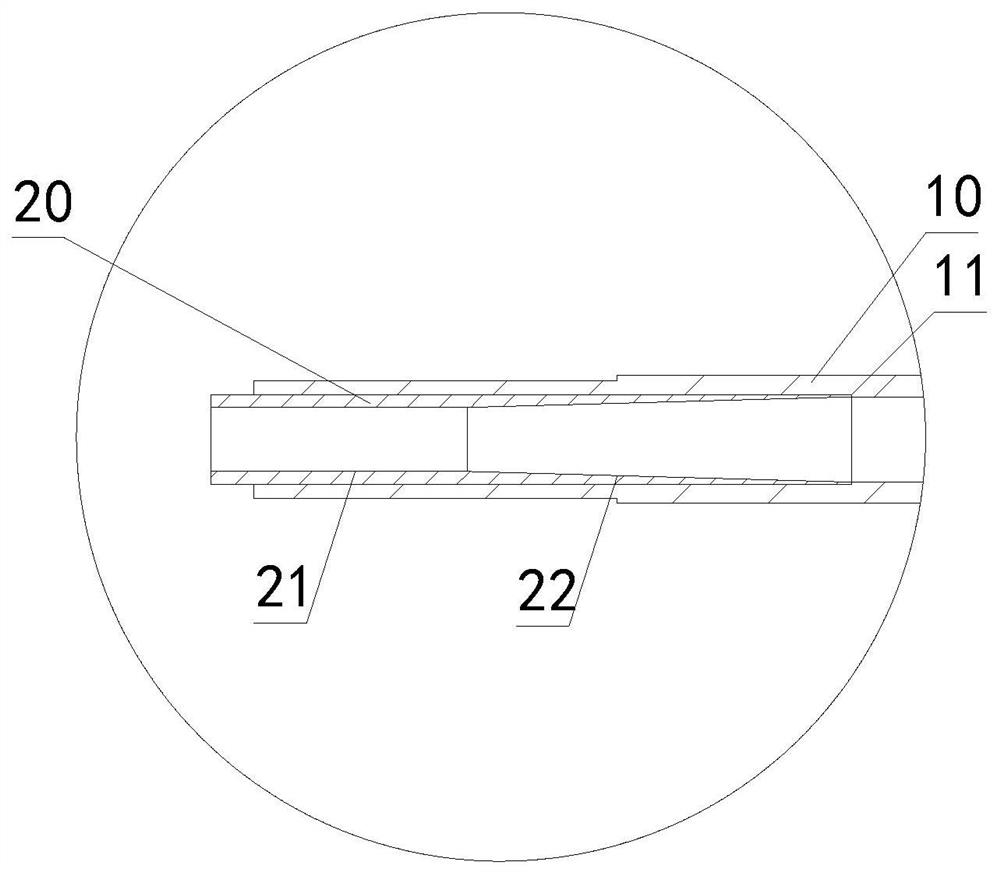

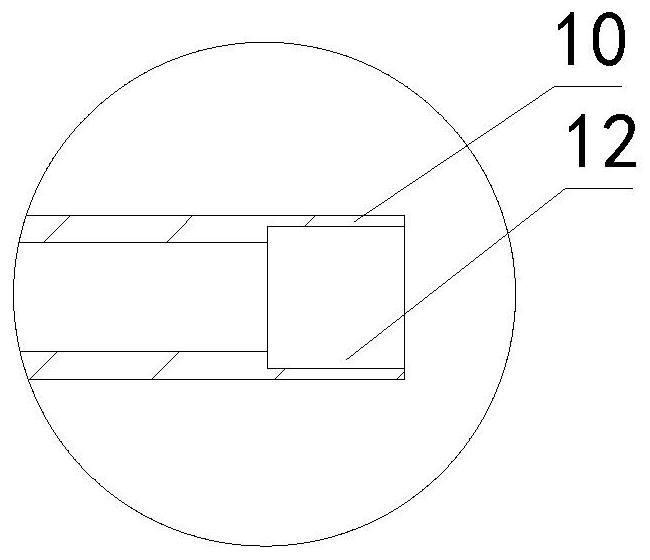

[0027] Such as Figure 1-3 As shown, the combined weft yarn nozzle provided by the present invention includes an outer tube 10 and an inner tube 20 arranged coaxially, the length of the outer tube 10 is at least 5 times that of the inner tube 20, the outer tube 10 is a straight tube, and the inner tube 20 is embedded Set at the end of the outer tube 10 close to the nozzle, the weft yarn passes through the inner tube 20 and the outer tube 10 from left to right in sequence, the outer wall of the inner tube 20 and the inner wall of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com