Sulfur hexafluoride gas leak detection alarm apparatus and working method thereof

A technology of sulfur hexafluoride gas and alarms, which is applied in chemical instruments and methods, alarms, gas treatment, etc., can solve the problems of reduced safety performance, internal gas leakage, and poor safety performance, so as to improve safety performance and improve Effects of operation, effects of improving safety and effectiveness of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

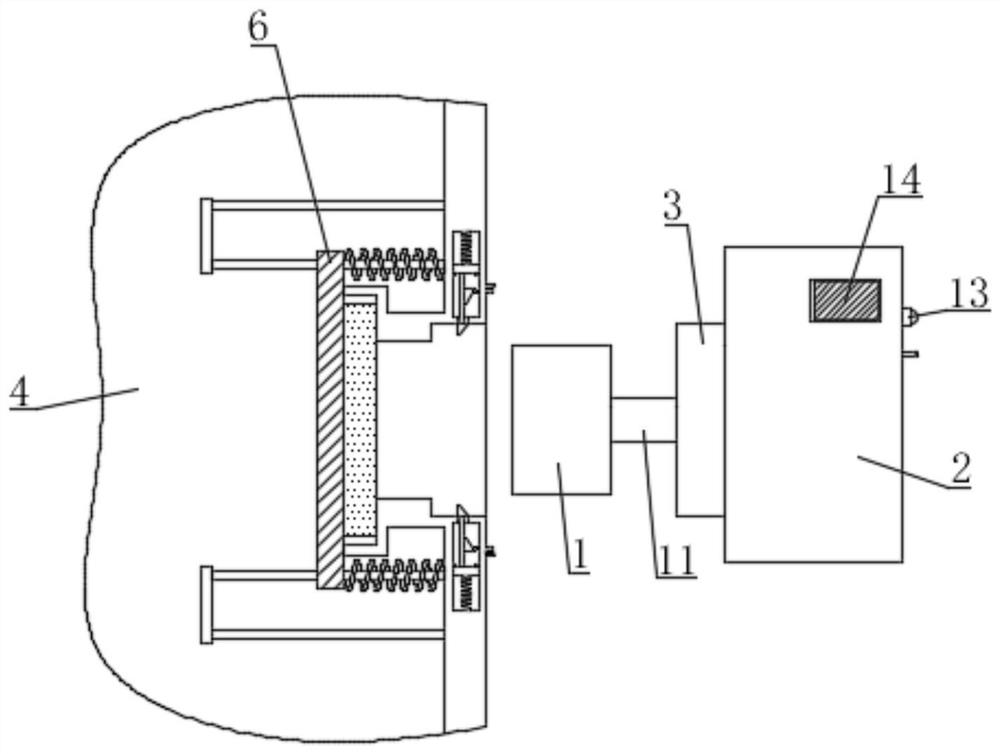

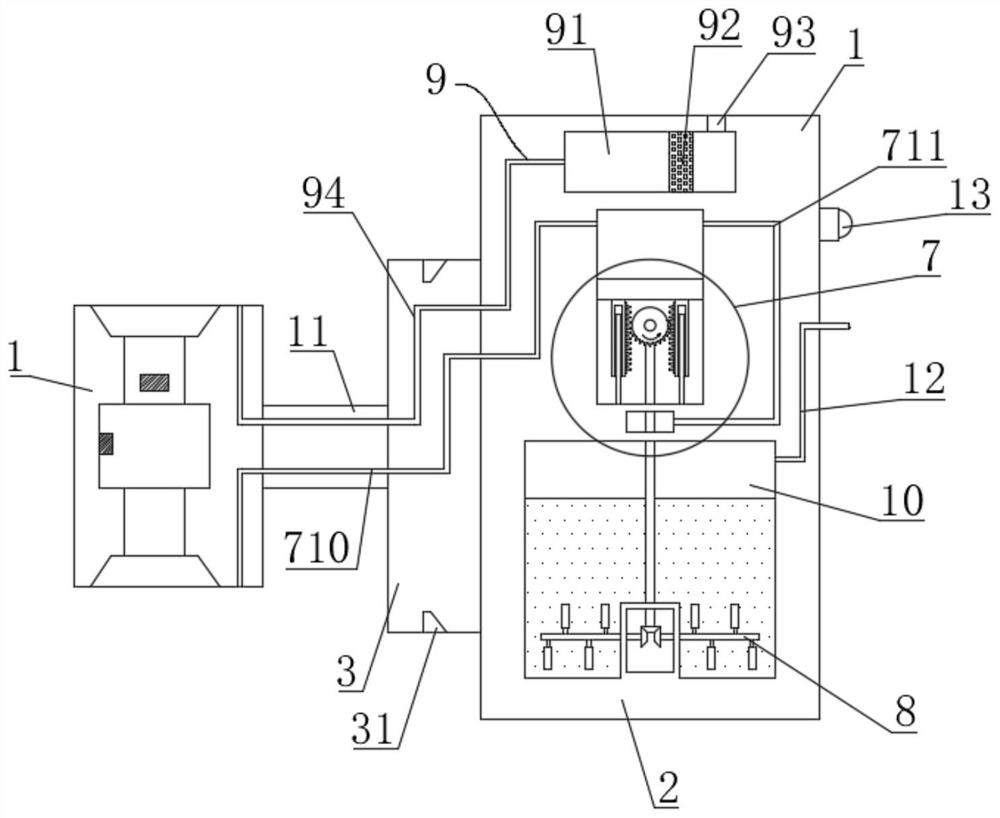

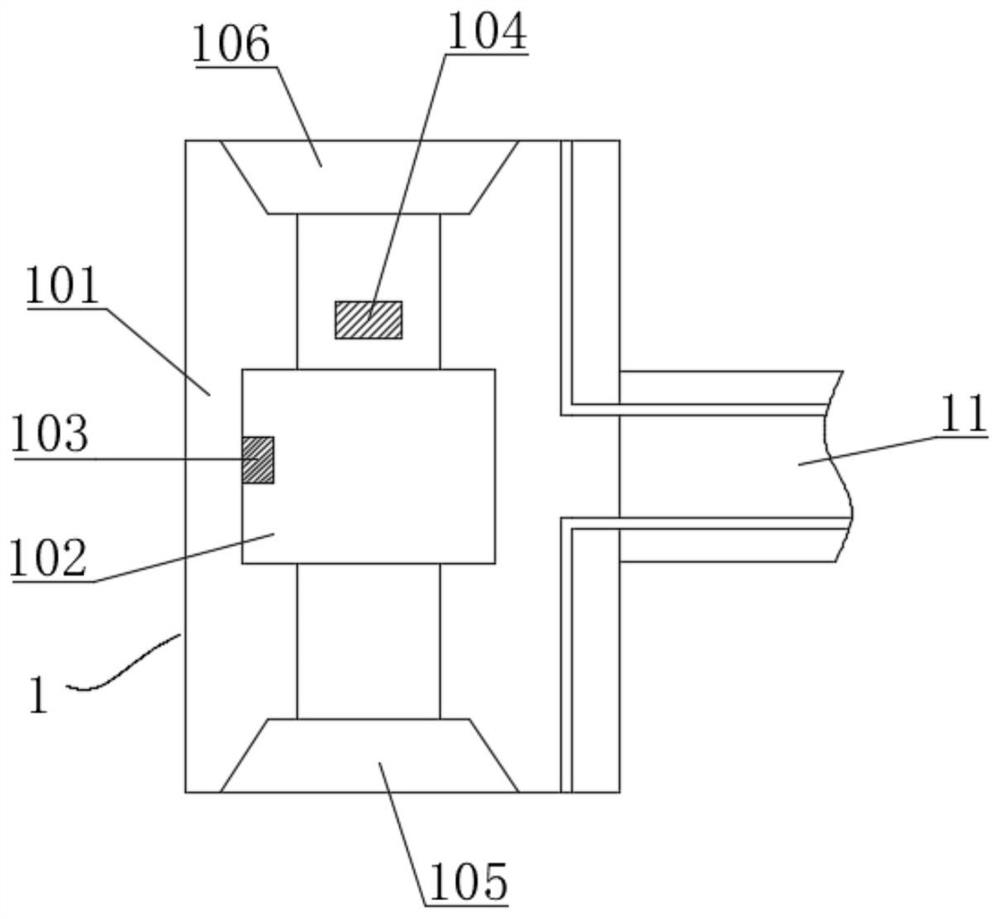

[0057] Such as Figure 1-9 As shown, the sulfur hexafluoride gas leak detection and alarm device proposed by the present invention includes a detection component 1, and the detection component 1 is installed on the high-voltage electrical cabinet 4, and the high-voltage electrical cabinet 4 is provided with an inner sealing groove 41, an outer sealing groove 42 and A communication port 43, and the communication port 43 communicates with the inner seal groove 41 and the outer seal groove 42, the sizes of the inner seal groove 41 and the outer seal groove 42 are larger than the size of the communication port 43, and the detection assembly 1 includes a detection box 101 and a detection sensor group 103 With fan 104, a detection chamber 102 is provided in the detection box 101, and the top of the detection box 101 is provided with an air inlet 105 communicated with the detection chamber 102, and the bottom of the detection box 101 is provided with an air outlet 106 communicated wit...

Embodiment 2

[0065] Such as figure 1 , Figure 9 and Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that a fast fixing assembly 5 for fixing the sealing plate 3 is installed on the high-voltage electrical cabinet 4, the quick fixing assembly 5 includes a positioning triangle block 501, and a high-voltage electrical cabinet 4 is equipped with The upper and lower sets of placement cavities 502, the placement cavities 502 are equipped with a slider 504 and a first spring 505, and the side of the slider 504 away from the outer seal groove 42 is connected to the first spring 505; the positioning triangular block 501 is located on the outer seal In the groove 42, a vertically arranged first connecting rod 503 is installed on the side of the slider 504 close to the outer sealing groove 42, and the other end of the first connecting rod 503 is connected with the positioning triangle block 501, and the upper and lower sides of the sealing plate 3 Positioning slots ...

Embodiment 3

[0069] Such as Figure 11 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the extruded triangular block 506 is fixedly installed on the first connecting rod 503 by bolts, and the inclined surface with the extruded triangular block 506 is installed in the placement cavity 502 The contacting extrusion ball 507, the outer wall of the high-voltage electrical cabinet 4 is fixed with a connecting seat 511 by bolts, and the bottom of the connecting seat 511 is slidingly installed with a pressing plate 509, and a pressing bar 508 is installed on the pressing plate 509, and the pressing bar 508 is away from One end of the pressing plate 509 extends into the placement cavity 502 and is connected with the extrusion ball 507, and a second spring 510 is provided between the pressing plate 509 and the high-voltage electrical cabinet 4;

[0070] When the detection device needs to be disassembled, pressure is applied to the pressing plate 509, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com