LED packaging structure and manufacturing method thereof

A technology of LED packaging and manufacturing method, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of abnormal dispensing device, exposed light conversion layer, difficulty in mass production, etc., so as to facilitate dispensing and filling, and avoid blackening failure. , to ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

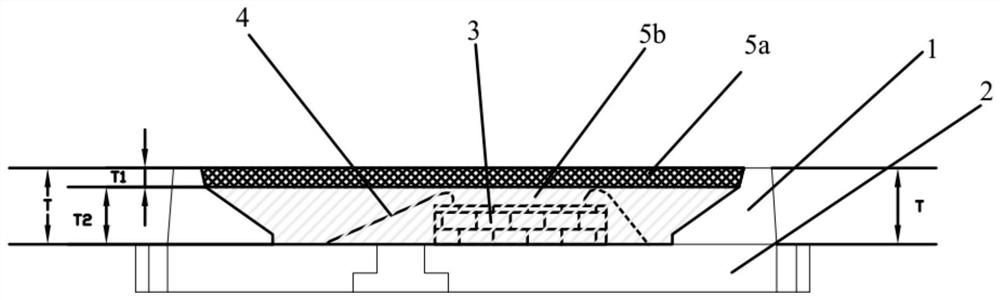

[0046] A LED packaging structure, such as figure 1 As shown, it includes a bracket, LED chips 3, wires 4 and fluorescent glue 5. The bracket includes a bracket cup 1 and a conductive substrate 2. The bracket cup 1 is bowl-shaped, and the bottom of the bracket cup 1 is fixed on the conductive substrate 2. surface. The LED chip 3 is fixed on the conductive substrate 2 and is located in the bracket cup 1; one end of the wire 4 is connected to the LED chip 3, and the other end is connected to the conductive substrate 2, so that the LED chip 3 and the conductive substrate 2 are electrically connected. Fluorescent glue 5 is filled in the bracket bowl cup 1, and the fluorescent glue 5 is composed of an upper layer of silica gel layer 5a and a lower layer of light conversion layer 5b, and the light conversion layer 5b is coated on the LED chip 3 to seal it in the bracket bowl cup 1, The silica gel layer 5a covers the upper surface of the light conversion layer 5b to isolate the light...

experiment example 1

[0057] Glue experiment.

[0058] Take the fluorescent glue in the examples and comparative examples respectively, put them into the glue dispenser, turn on the switch of the glue dispenser, fill the fluorescent glue into the bracket bowl, and observe the effect of glue dispensing. If the surface of the colloid is flat after dispensing, it means that the dispensing is normal. If there is agglomeration of phosphor powder, wrinkles on the surface of the colloid or other abnormal phenomena after dispensing, it means that the dispensing is abnormal. After dispensing, use a centrifugal device to centrifugally settle under the same conditions to observe the state of the colloid section.

[0059] Experimental results: the fluorescent glue of Example 1 is normally dispensed, and the surface of the colloid is smooth and smooth ( Figure 4 ), a stable silica gel layer and light conversion layer were formed after centrifugal sedimentation, and the surface of the light conversion layer wa...

experiment example 2

[0061] Package brightness experiment.

[0062] Experimental method: Seal the sample in the 2835 package, and use 100mA to light up the test. The test results are shown in Table 1.

[0063] Table 1. Brightness comparison of LED package structure

[0064]

[0065]

[0066] It can be seen from the above table that the package luminance of Example 1 and Comparative Example 1 are equivalent, obviously better than that of Comparative Example 2, the brightness of which is 2.8% and 2.4% higher respectively. Adding diluent can reduce the viscosity of fluorescent glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com