Production process of dried bean curd with stomach nourishing effect

A production process and cowhide technology, applied in the functions of food ingredients, food ingredients as taste improvers, and oily food ingredients, etc., can solve the problem that cowhide dried bean curd can not be fully tasted, etc., to enhance immunity, reduce blood sugar, Improve product experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

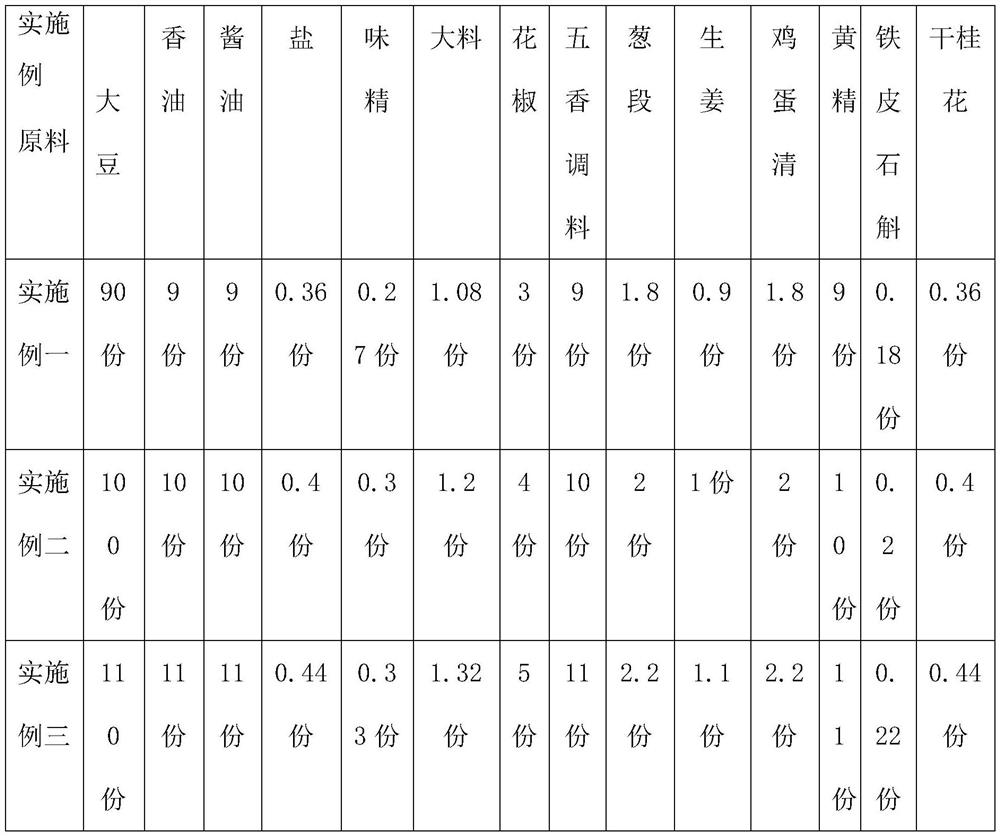

Embodiment 1

[0027]Embodiment 1: The production process of cowhide dried tofu with the effect of nourishing the stomach, including the following raw materials: 90 parts of soybeans, 9 parts of sesame oil, 9 parts of soy sauce, 0.36 parts of salt, 0.27 parts of monosodium glutamate, 1.08 parts of aniseed, 0.9 parts of Chinese prickly ash , 9 parts of spiced seasonings, 1.8 parts of scallions, 0.9 parts of ginger, 1.8 parts of egg whites, 9 parts of sealwort, 0.18 parts of Dendrobium candidum, 0.36 parts of dried sweet-scented osmanthus, including the following steps: Step 1, soaking and peeling: select high-quality and large-sized particles Uniform soybeans, soak the selected soybeans in water for 12 hours, the ratio of water to soybeans is 1:2.5, and the water temperature is 5°C. During the soaking process, rub the outer skin of the soybeans with the soybeans After separation and soaking, use a sieve to sieve the bean skin and soybeans, and take them out for later use; Step 2, grind them in...

Embodiment 2

[0028] Embodiment 2: The production process of cowhide dried bean curd with the function of nourishing the stomach, including the following raw materials: 100 parts of soybeans, 10 parts of sesame oil, 10 parts of soy sauce, 0.4 parts of salt, 0.3 parts of monosodium glutamate, 1.2 parts of aniseed, 1 part of Chinese prickly ash , 10 parts of five-spice seasoning, 2 parts of spring onion, 1 part of ginger, 2 parts of egg white, 10 parts of sealwort, 0.2 part of Dendrobium candidum, 0.4 part of dried osmanthus, including the following steps: Step 1, soaking and peeling: select high-quality and small-sized Uniform soybeans, soak the selected soybeans in water for 18 hours, the ratio of water to soybeans is 1:2.5, and the water temperature is 10°C. During the soaking process, rub the outer skin of the soybeans with the soybeans After separation and soaking, use a sieve to sieve the bean skin and soybeans; step 2, grind into paddles: put the soaked and cleaned soybeans in step 1 in...

Embodiment 3

[0029] Embodiment 3: The production process of cowhide dried bean curd with the function of nourishing the stomach, including the following raw materials: 110 parts of soybeans, 11 parts of sesame oil, 11 parts of soy sauce, 0.44 parts of salt, 0.33 parts of monosodium glutamate, 1.32 parts of aniseed, 1.1 parts of Chinese prickly ash , 11 parts of spiced seasonings, 2.2 parts of scallions, 1.1 parts of ginger, 2.2 parts of egg whites, 11 parts of Polygonatum, 0.22 parts of Dendrobium candidum, 0.44 parts of dried sweet-scented osmanthus, including the following steps: Step 1, soaking and peeling: select high-quality and small-sized Uniform soybeans, soak the selected soybeans in water for 24 hours, the ratio of water to soybeans is 1:2.5, and the water temperature is 15°C. During the soaking process, rub the outer skin of the soybeans with the soybeans After separation and soaking, use a sieve to sieve the bean skin and soybeans, and take them out for later use; Step 2, grind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com