Composite surface type X-ray piezoelectric deformable mirror

An X-ray and deformable mirror technology, applied in the field of X-ray optical wavefront correction, can solve the problems of difficult adjustment and high cost, and achieve the effect of increasing the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

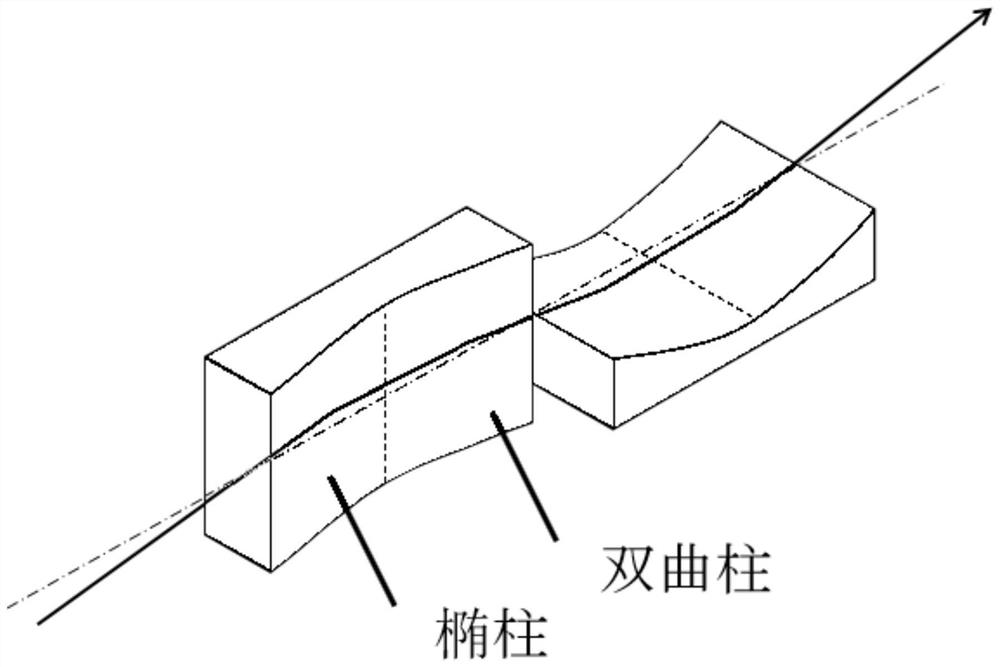

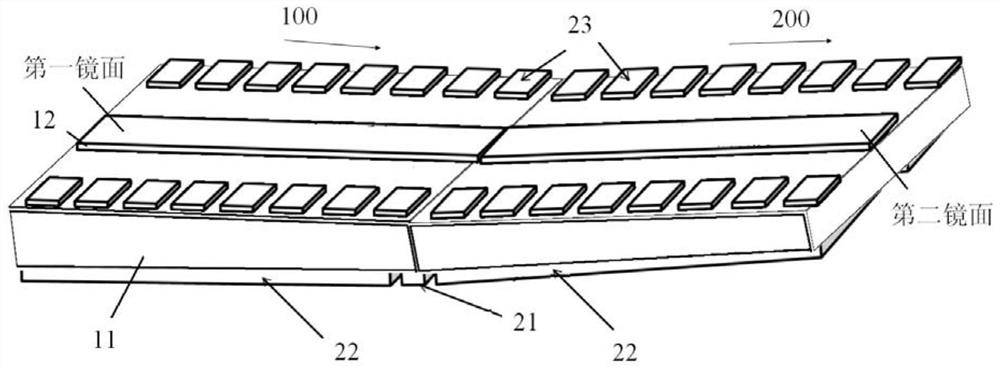

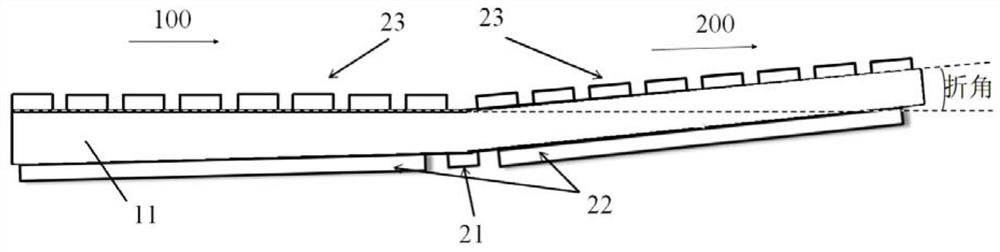

[0029] like Figure 2A-Figure 2B The X-ray piezoelectric definition mirror of a composite face type according to an embodiment of the present invention is shown. The X-ray piezoelectric deformed mirror is a mirror, and its substrate surface is a rectangular shape, or is designed as a special shape to compensate for a surface distortion caused by a pressure.

[0030] The X-ray piezoelectric definitive mirror includes a substrate 11 (i.e., a mirror substrate) and an optical reflection film 12 disposed above the substrate 11, according to the requirements of the composite surface, the upper surface of the optical reflection film 12 is divided into Two mirrors (ie, two optical surfaces). In the present embodiment, the optical reflection film 12 is disposed above the center position above the substrate 11. Among them, at least one of the upper surfaces, the lower surface, and the side surface of the substrate 11 is provided with a piezoelectric ceramic sheet such that the two mirror sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com