PE (polyethylene) electrostatic protective film as well as preparation method and coating equipment thereof

A protective film, electrostatic technology, applied in conductive coatings, film/sheet release coatings, coatings and other directions, can solve the problem of poor anti-static performance and high temperature resistance, difficult to meet the requirements of use, electrostatic liquid coating machine It is easy to adjust and other problems, and achieves the effect of improving anti-static performance, good high temperature resistance and meeting the requirements of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

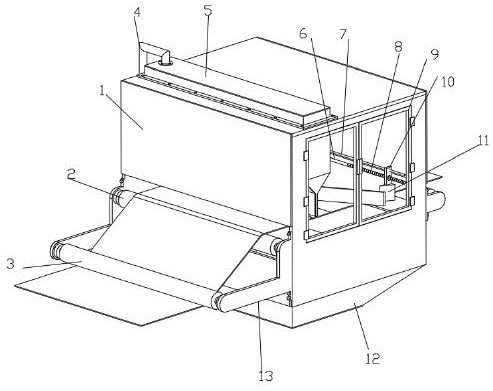

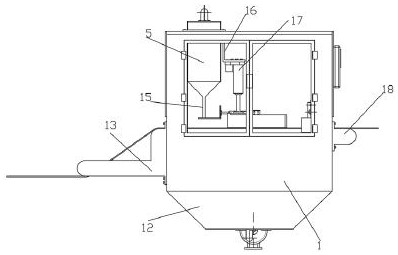

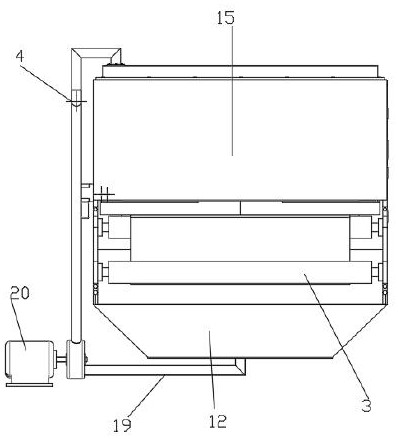

Image

Examples

Embodiment 1

[0035] A PE electrostatic protective film, the PE electrostatic protective film comprises a PE base film layer, an electrostatic liquid layer, a high temperature resistant layer and an adhesive layer, the PE base film layer is provided with an electrostatic liquid layer, and the electrostatic liquid layer is provided with an anti-static liquid layer. High-temperature layer, the top of the high-temperature-resistant layer is provided with a glue layer, and the thicknesses of the PE base film layer, electrostatic liquid layer, high-temperature-resistant layer, and glue layer are 50 μm, 3.5 μm, 3.7 μm, and 5 μm, respectively.

[0036] The electrostatic liquid layer is composed of the following components in percentage by weight: ethanol 65%, conductive liquid 1.6%, film forming agent 14%, vinyl resin type amide polymer 1.1% and water 30%

[0037] A preparation method of PE electrostatic protective film, the preparation method steps are as follows:

[0038] Step 1. Put ethanol, co...

Embodiment 2

[0043]A PE electrostatic protective film, the PE electrostatic protective film comprises a PE base film layer, an electrostatic liquid layer, a high temperature resistant layer and an adhesive layer, the PE base film layer is provided with an electrostatic liquid layer, and the electrostatic liquid layer is provided with an anti-static liquid layer. High-temperature layer, the top of the high-temperature-resistant layer is provided with a glue layer, and the thicknesses of the PE base film layer, electrostatic liquid layer, high-temperature-resistant layer, and glue layer are 70 μm, 2.5 μm, 2.6 μm, and 4 μm, respectively.

[0044] The electrostatic liquid layer is composed of the following components in percentage by weight: ethanol 73%, conductive liquid 10%, film forming agent 2.8%, vinyl resin type amide polymer 1.3% and water 12.9%

[0045] A preparation method of PE electrostatic protective film, the preparation method steps are as follows:

[0046] Step 1. Put ethanol, c...

Embodiment 3

[0051] A PE electrostatic protective film, the PE electrostatic protective film comprises a PE base film layer, an electrostatic liquid layer, a high temperature resistant layer and an adhesive layer, the PE base film layer is provided with an electrostatic liquid layer, and the electrostatic liquid layer is provided with an anti-static liquid layer. High temperature layer, the top of the high temperature resistant layer is provided with an adhesive layer, and the thicknesses of the PE base film layer, electrostatic liquid layer, high temperature resistant layer, and adhesive layer are 90 μm, 3 μm, 4.3 μm, and 6 μm, respectively.

[0052] The electrostatic liquid layer is made up of the following components in percentage by weight: ethanol 82%, conductive liquid 6%, film forming agent 3.5%, vinyl resin type amide polymer 1.5% and water 7%

[0053] A preparation method of PE electrostatic protective film, the preparation method steps are as follows:

[0054] Step 1. Put ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com