Micromotor mounting plate punching device based on crack detection and film positioning

A technology of crack detection and punching device, which is applied in metal processing and other directions, can solve the problems of slow processing of micro-motor mounting plates and inability to punch holes in multiple positions at the same time, so as to save processing time and improve processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

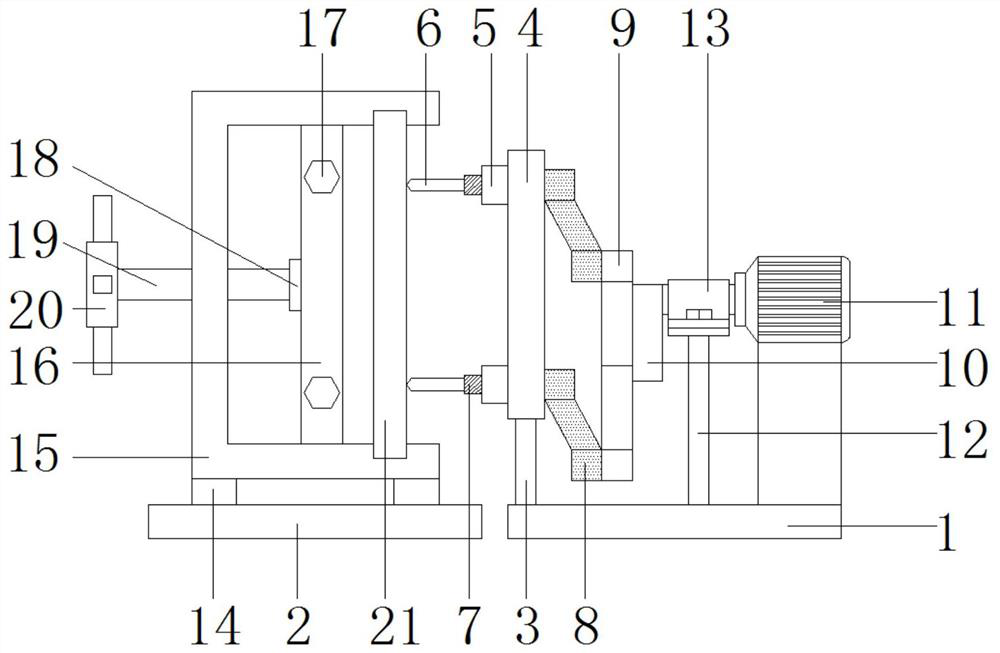

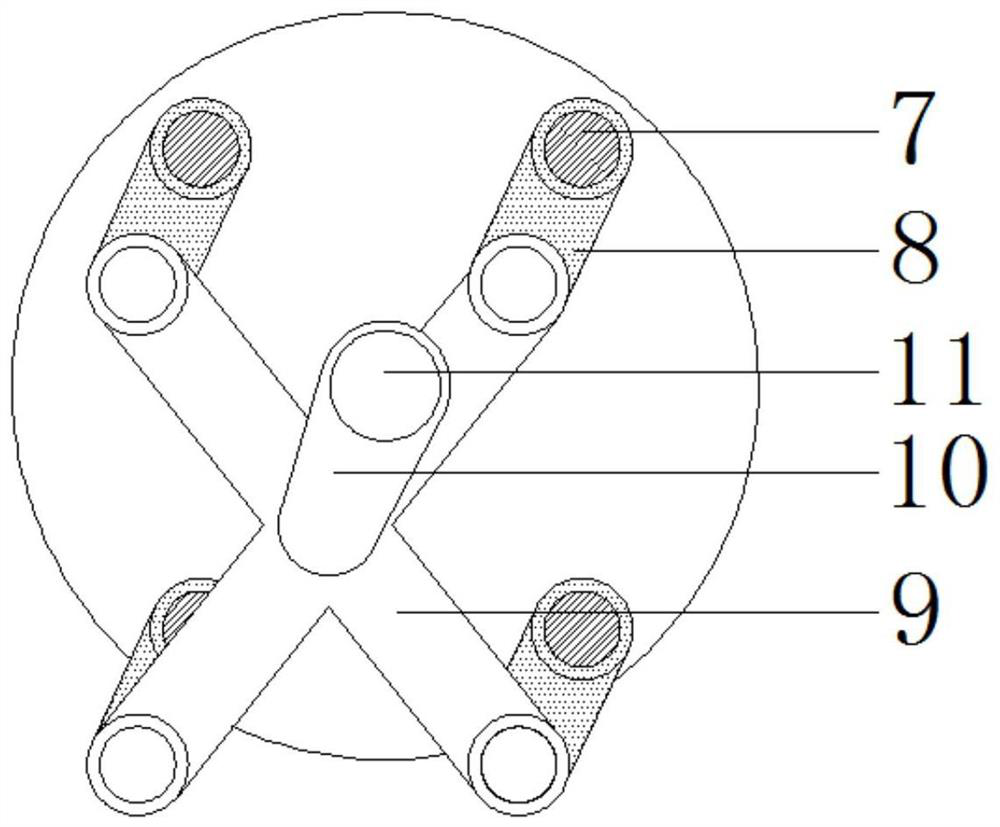

[0022] see Figure 1-2 , a micro-motor mounting plate punching device based on crack detection and film positioning, including a first base plate 1 and a second base plate 2, a support plate 3 is fixedly connected above the left end of the first base plate 1, and a circle is fixedly connected above the support plate 3 Disk 4, the left side of disk 4 is fixedly connected with the first bearing 5, the first bearing 5 is provided with four groups and evenly distributed on the outer wall of the disk 4; the inside of the first bearing 5 and the disk 4 is provided with a rotating sleeve 7 , the left end of the rotary sleeve 7 is fixedly equipped with a drill bit 6, and the right end is provided with a rotating oblique rod 8, the right side of the rotating oblique rod 8 is provided with a cross 9, the middle end of the cross 9 is provided with a rocking plate 10, and the right side of the rocking plate 10 is One end is fixedly connected with a high-speed motor 11 , and the lower part...

Embodiment 2

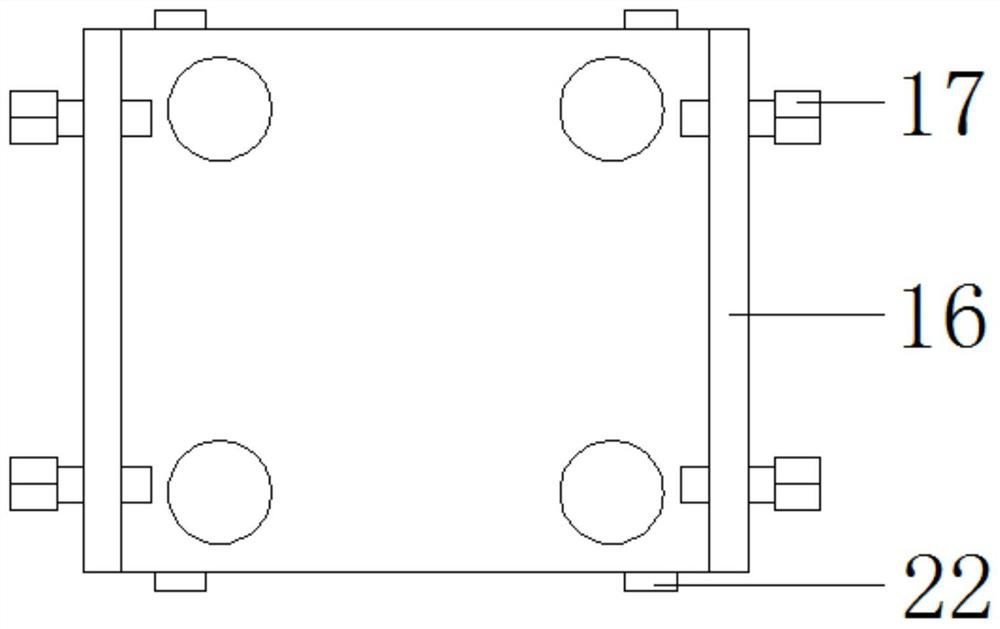

[0026] see figure 1 , 3 and Figure 4 , the upper two ends of the second bottom plate 2 are fixedly connected with pads 14, the top of the pads 14 is fixedly connected with a concave plate 15, the inside of the concave plate 15 is slidingly connected with a movable splint 16, and the left side of the movable splint 16 is fixedly connected There is a second bearing 18, the inside of the second bearing 18 is fixedly connected with a screw rod 19, and the screw rod 19 is screwed with the concave plate 15. A handle 20 is fixedly connected to the left end of the screw rod 19 . A mounting plate 21 is clamped inside the right side of the concave plate 15 . Adjusting bolts 17 are arranged on the front and rear sides of the movable splint 16 . A slide block 22 is fixedly connected to the top and bottom of the movable splint 16 , and the slide block 22 is slidably connected to the inside of the concave plate 15 .

[0027] Specifically, during use, the mounting plate 21 to be proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com