Method for recovering metallic iron from carbon-containing converter steel slag

A technology of converter steel slag and metal iron, applied in the field of recycling metal iron resources, can solve the problems of not being comprehensively utilized and low recycling efficiency, and achieve the effects of good economy and practicability, convenient operation, and large particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

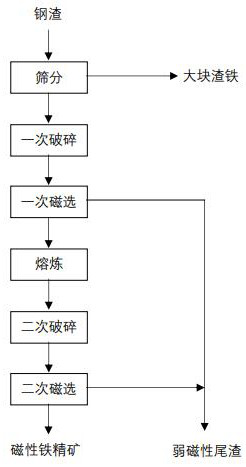

Image

Examples

Embodiment 1

[0025] S1: Sieve, take 25kg of converter steel slag with a grade of 21.5% of wine iron and steel, separate large pieces of slag and iron by using an iron remover, and obtain 24.78kg of converter steel slag from which large pieces of slag and iron have been removed, wherein the particle size of large pieces of slag and iron is ≥100mm, and The separated bulk slag has a high grade of iron and iron and can be directly recycled as concentrate.

[0026] S2: primary crushing, the converter steel slag that removes large slag iron in S1 is crushed by a jaw crusher, so that the particle size of the broken converter steel slag is below 10mm;

[0027] S3: A magnetic separation, the converter steel slag obtained in S2 with a particle size below 10mm is subjected to dry magnetic separation with a belt-type permanent magnetic drum to obtain 5.45 kg of magnetic coarse slag and 19.33 kg of weak magnetic tailings; the belt-type permanent magnetic drum The surface magnetic induction is 0.13T, an...

Embodiment 2

[0033] S1: Screening, take 30kg of converter steel slag with a grade of 22% of wine iron and steel, and separate the bulk slag and iron by using the iron remover to obtain 29kg of converter steel slag with the bulk slag and iron removed, wherein the particle size of the bulk slag and iron is ≥100mm, and separate The large slag produced has a high content of iron and iron, and can be directly recycled as a concentrate.

[0034] S2: primary crushing, the converter steel slag that removes large slag iron in S1 is crushed by a jaw crusher, so that the particle size of the broken converter steel slag is below 10mm;

[0035] S3: A magnetic separation, the converter steel slag obtained in S2 with a particle size of less than 10mm is subjected to dry magnetic separation with a belt-type permanent magnetic drum to obtain 6.38kg of magnetic coarse slag and 22.62kg of weak magnetic tailings; the belt-type permanent magnetic drum The surface magnetic induction intensity is 0.13T, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com