Electrochemistry-based material surface modification device

A surface modification and electrochemical technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problem of time-consuming and labor-intensive, and achieve the effect of ensuring the constant concentration, ensuring the appearance and quality, and saving labor and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

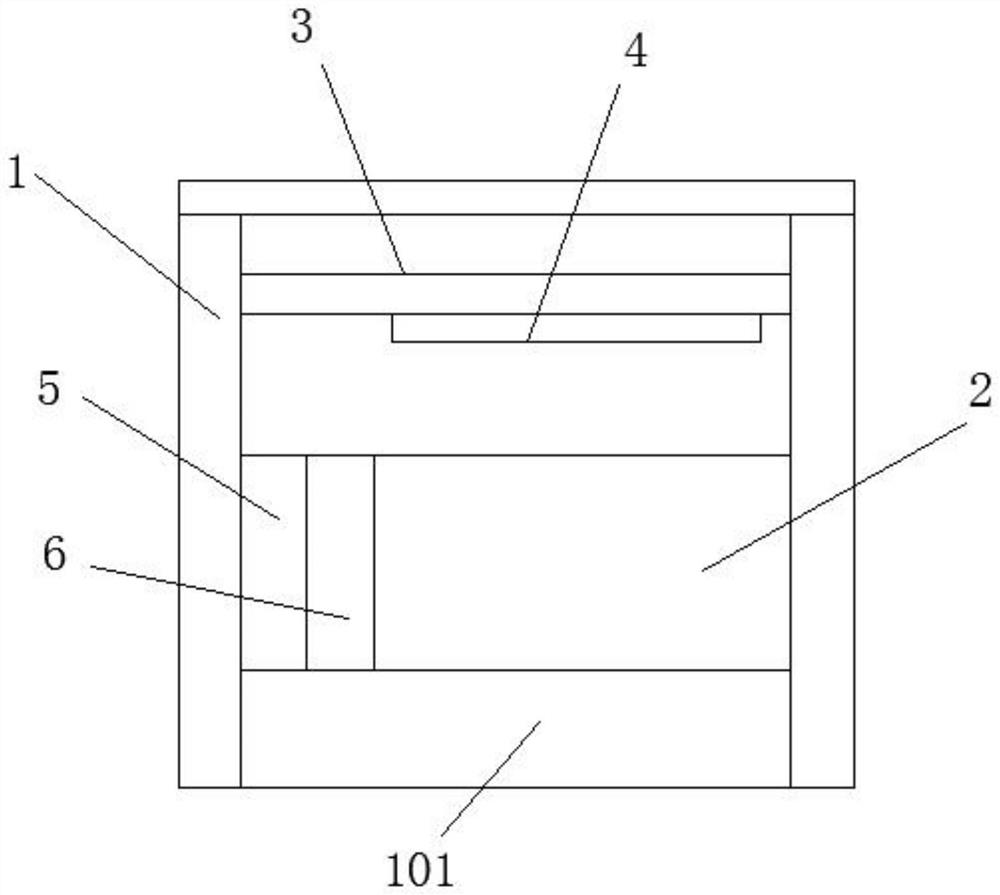

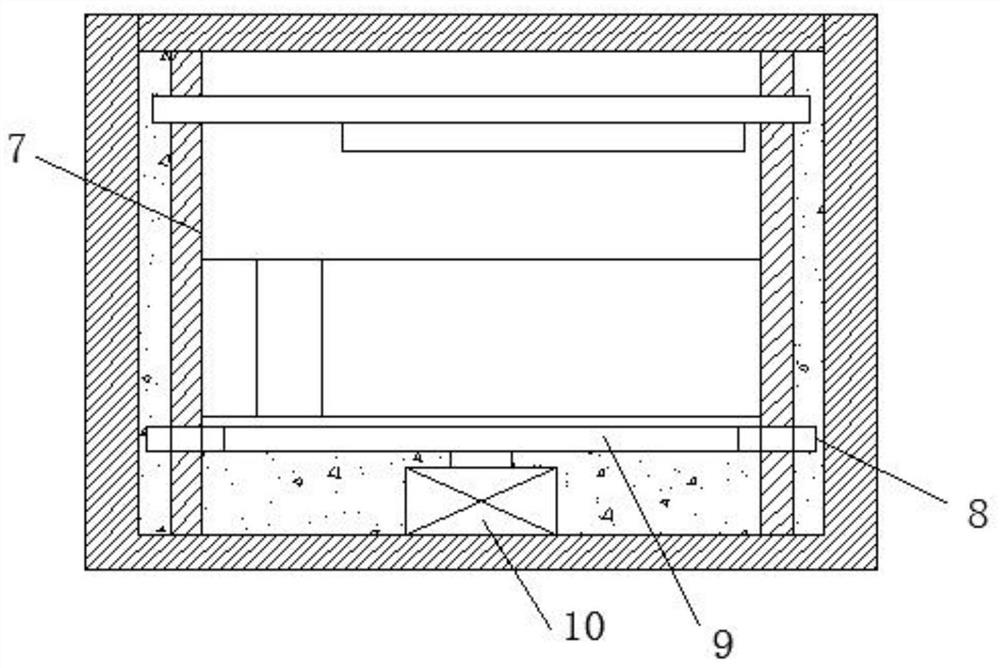

[0036] see Figure 1-Figure 3 , a material surface modification device based on electrochemistry, comprising a frame 1, an electroplating box 2 arranged on the frame 1, a low-voltage power supply electrically connected to the electroplating box 2, a fixed lifting device, a feeding device, and a feeding and stirring device

[0037] Specifically, in this embodiment, the fixed lifting device includes two lead screws 7, which are respectively arranged on both sides of the electroplating box 2. The threads on the two lead screws 7 are opposite, and a fixed lifting rod is arranged between the two lead screws 7. 3. The two ends of the fixed lifting rod 3 are threadedly connected with the lead screws 7 on both sides respectively, and the lower ends of the two lead screws 7 are provided with drive components;

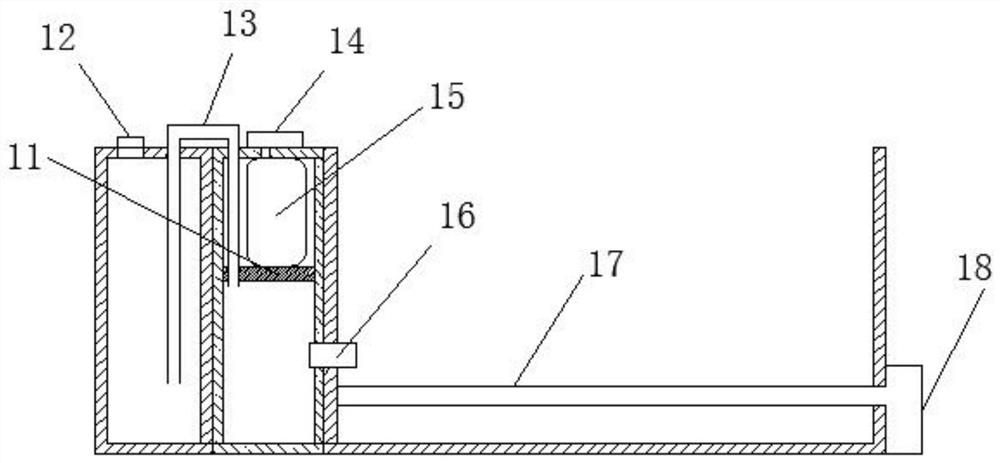

[0038] Feeding device wherein comprises feeding box 6, is arranged on electroplating box 2 outer walls, is communicated with electroplating box 2 by one-way valve 16; , located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com