Yielding anchor rod and supporting method

A technology of letting and pressing bolts and bolts, used in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve problems such as failure of the anchor head, inability to effectively absorb the impact energy of impact ground pressure, and rod body breaking, etc. Let the pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

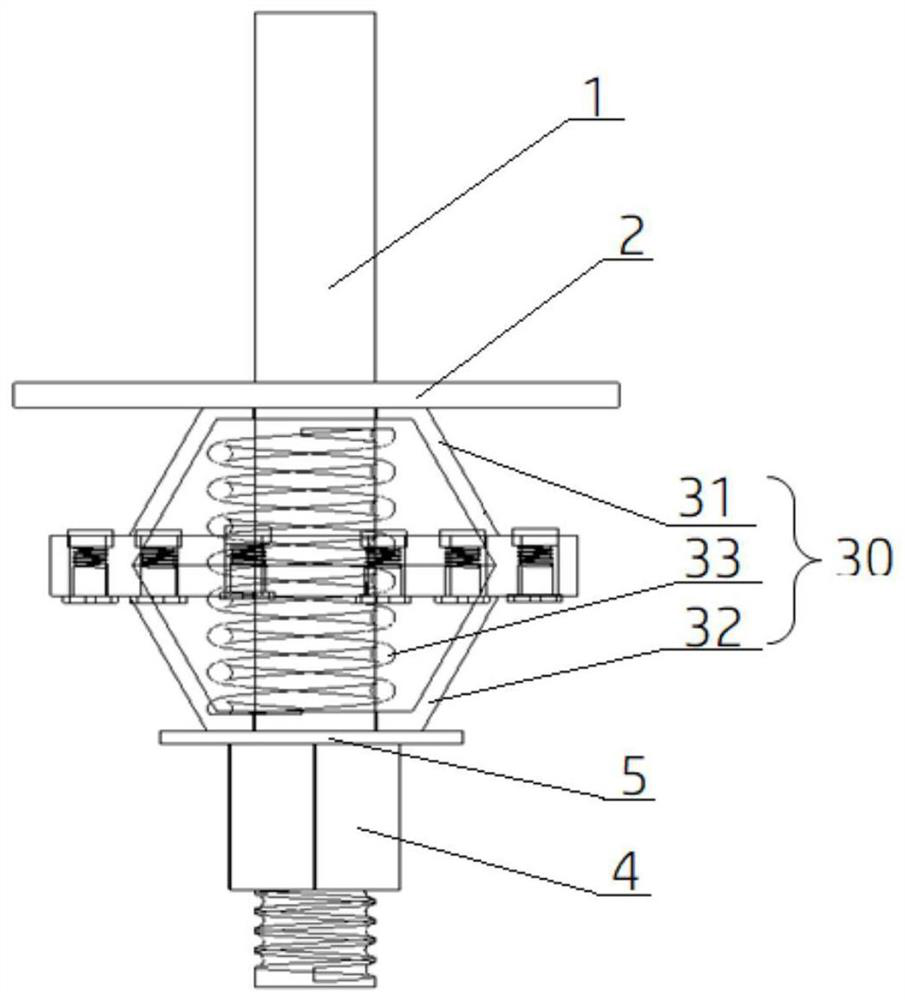

[0024] Bolt support has the characteristics of economy, effectiveness and high efficiency, and is the preferred active support method for surrounding rock in coal mines. The bearing capacity of the traditional bolt is limited, and the elongation of the bolt body is low and the toughness is poor. Under the impact energy generated by the impact rock pressure, the surrounding rock deforms and acts on the bolt, so that the bolt is elongated, and the elongated Anchor bolts are often unable to resist the remaining impact energy due to reduced strength, resulting in damage to the pallet or loosening of the pre-tightening nut, resulting in safety accidents, and cannot adapt to the large deformation of the surrounding rock mass in deep roadways due to high stress.

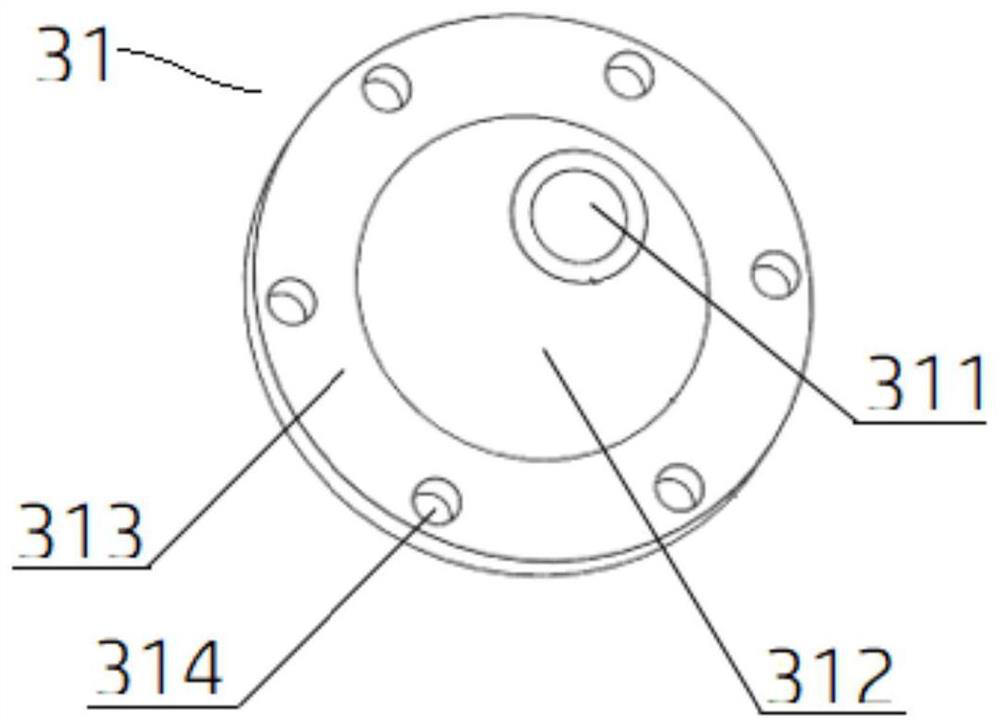

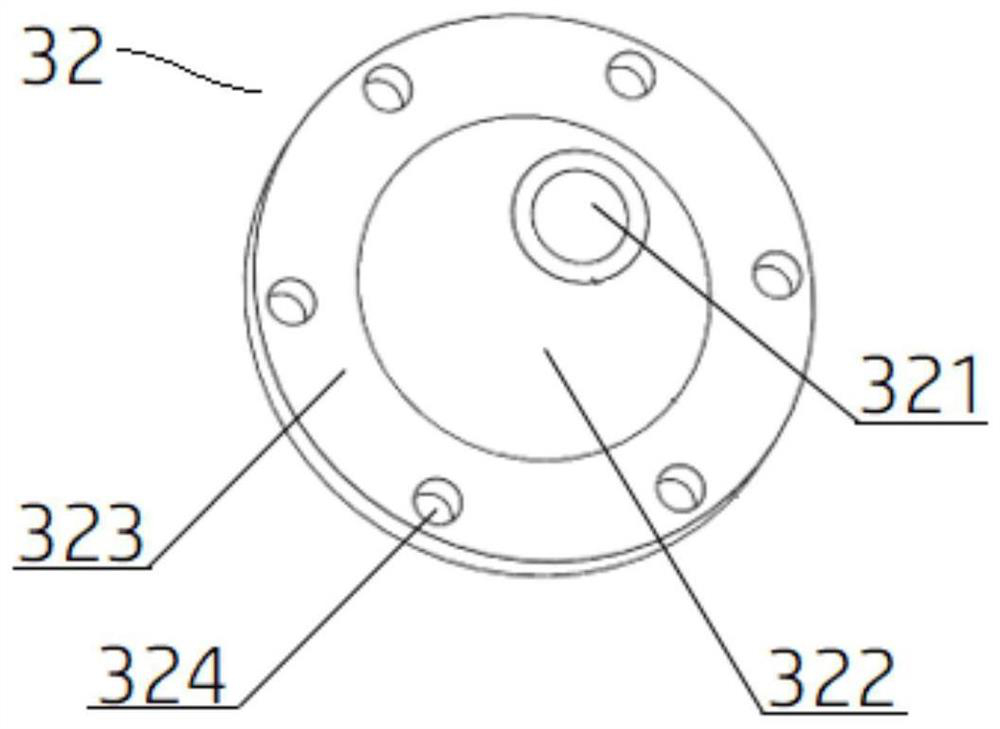

[0025] In order to ensure the co-deformation of the bolt and the surrounding rock, absorb the impact energy generated by the impact rock pressure, control the deformation of the surrounding rock, and prevent safety accidents...

Embodiment 2

[0050] see Figure 4 As shown, the embodiment of the present invention provides a support method, which is characterized in that the yielding anchor described in any one of the first embodiment is adopted, comprising the steps of:

[0051] S01. Insert the anchor rod into the preset anchor rod hole, install a tray, a pressure relief device and a pre-tightening nut at the end of the anchor rod, and complete the pre-tightening support of the anchor rod.

[0052] Specifically, the anchor rod hole is drilled at the anchor rod installation position by a drilling rig, and then the anchoring agent is placed at the end of the anchor rod hole, and then the anchor rod is inserted into the preset anchor rod hole, and the resin anchoring agent is sent to Preset anchorage in the anchor hole. Then connect the end of the anchor rod outside the anchor rod hole to the driving device, and the driving device drives the anchor rod to rotate to stir the anchoring agent. Wherein, the anchoring age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com