Anchor cable or anchor tray with polyurethane coating and manufacturing method thereof

A polyurethane and cladding technology is applied in the field of anchor cables or anchor rod trays and their production, which can solve the problems of easy rust and oxygen corrosion, easy loosening of trays, small pre-tightening force, etc. , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

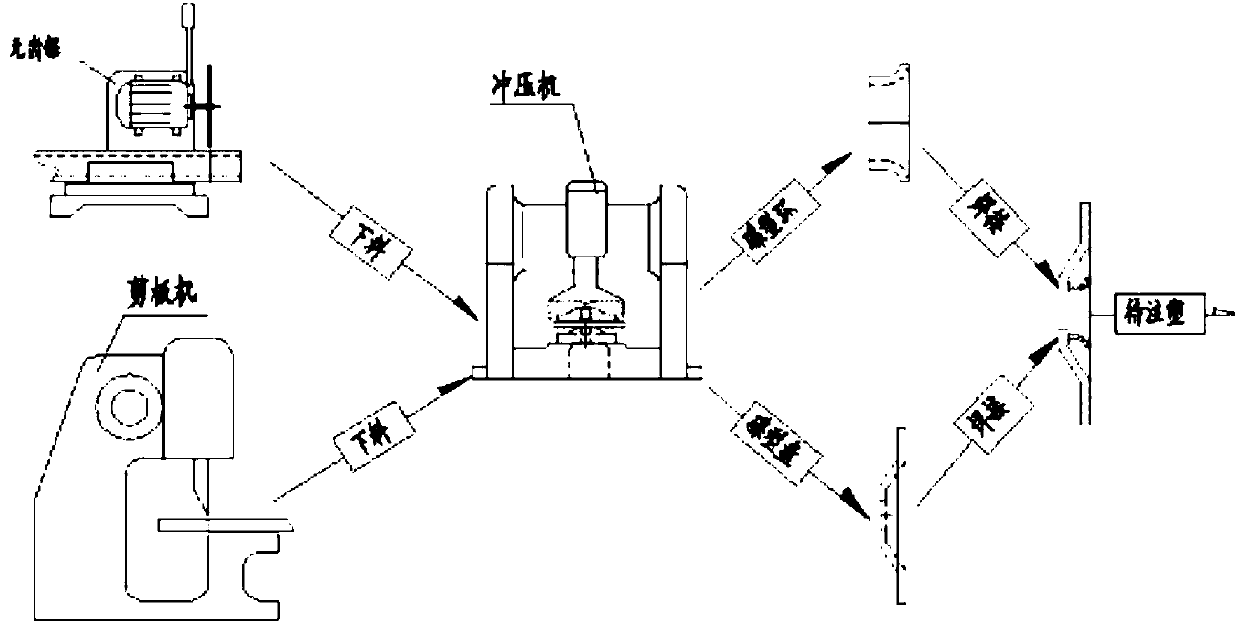

[0025] A method for making an anchor cable or anchor tray with a polyurethane coating, characterized in that the steps are as follows:

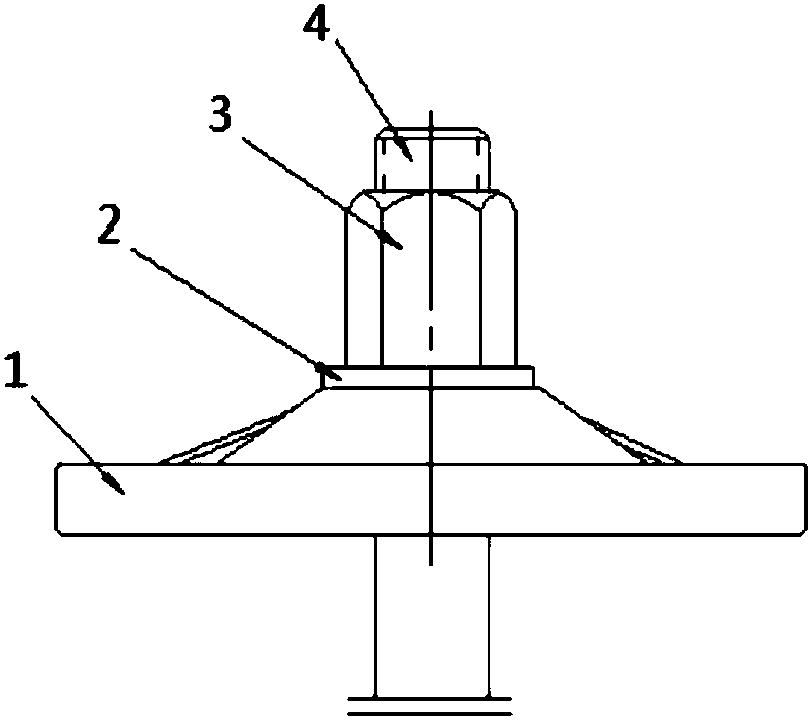

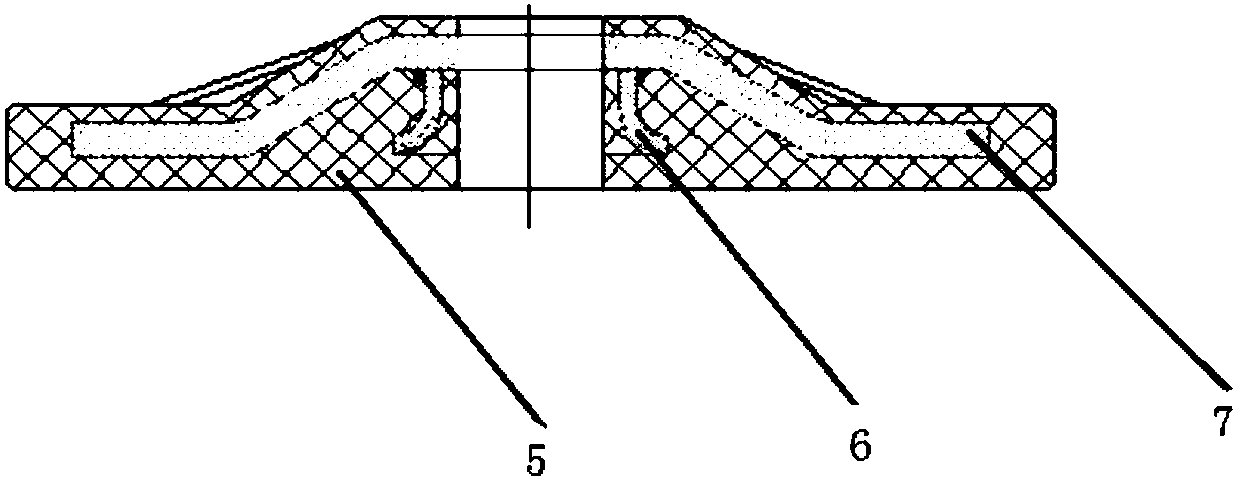

[0026] a. Stamping the pressure ring 6 and the dish-shaped disc 7 with a central through hole respectively;

[0027] b. Weld the pressure ring 6 to the bottom of the inner side of the disc 7 to form a disc-shaped metal bearing support member 1;

[0028] c. Add 100 parts of polymer polyurethane thermoplastic TPU-68D elastomer treated with coupling agent KH570, 10 parts of flame retardant HF-TPU, and 10 parts of antistatic agent E-1228 into a twin-screw extruder to extrude Obtain modified polyurethane particles after granulation;

[0029] d. Place the disc-shaped metal bearing support member 1 in the cavity of the injection mold, then put the modified polyurethane particles prepared in step c into an injection molding machine and inject and coat the surface of the disc-shaped metal bearing support member 1 to obtain For anchor cables or ancho...

Embodiment 2

[0031] A method for making an anchor cable or anchor tray with a polyurethane coating, characterized in that the steps are as follows:

[0032] a. Stamping the pressure ring 6 and the metal disc 7 with a central through hole respectively;

[0033] b. Weld the pressure ring 6 to the bottom of the inner side of the disc 7 to form a disc-shaped metal bearing support member 1;

[0034] c. Add 100 parts of polymer polyurethane thermoplastic TPU-68D elastomer treated with coupling agent KH570, 12 parts of flame retardant HF-TPU, and 5 parts of antistatic agent E-1228 into a twin-screw extruder to extrude Obtain modified polyurethane particles after granulation;

[0035] d. Place the disc-shaped metal bearing support member 1 in the cavity of the injection mold, then put the modified polyurethane particles prepared in step c into an injection molding machine and inject and coat the surface of the disc-shaped metal bearing support member 1 to obtain For anchor cables or anchor rod t...

Embodiment 3

[0037] A method for making an anchor cable or anchor tray with a polyurethane coating, characterized in that the steps are as follows:

[0038] a. Stamping the pressure ring 6 and the metal disc 7 with a central through hole respectively;

[0039] b. Weld the pressure ring 6 to the bottom of the inner side of the disc 7 to form a disc-shaped metal bearing support member;

[0040] c. Add 100 parts of polymer polyurethane thermoplastic TPU-68D elastomer treated with coupling agent KH570, 15 parts of flame retardant HF-TPU, and 12 parts of antistatic agent E-1228 into a twin-screw extruder to extrude Obtain modified polyurethane particles after granulation;

[0041] d. Place the disc-shaped metal bearing support member 1 in the cavity of the injection mold, then put the modified polyurethane particles prepared in step c into an injection molding machine and inject and coat the surface of the disc-shaped metal bearing support member 1 to obtain For anchor cables or anchor rod tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com