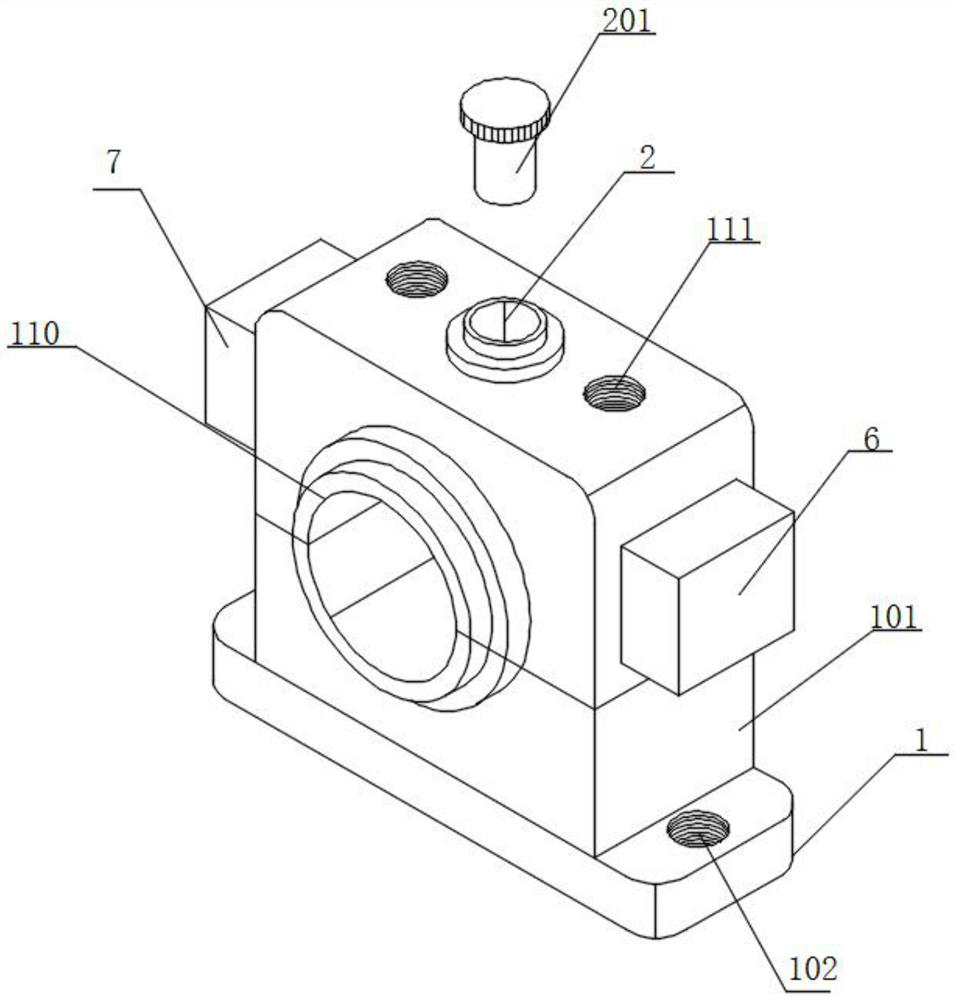

Sliding bearing with high-stability mounting support

A technology for sliding bearings and mounting supports, which is applied in bearing cooling, bearing assembly, safety devices, etc., can solve the problems of loose connection, poor heat dissipation effect, lack of detection structure, etc., and achieve tight connection, increased stability, and enhanced The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

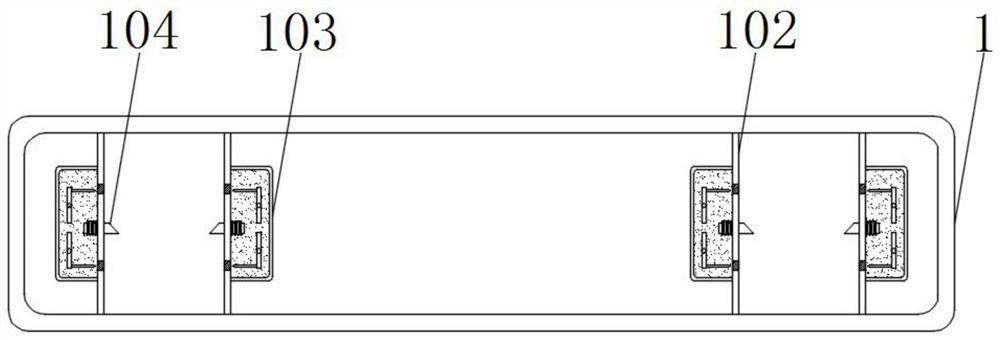

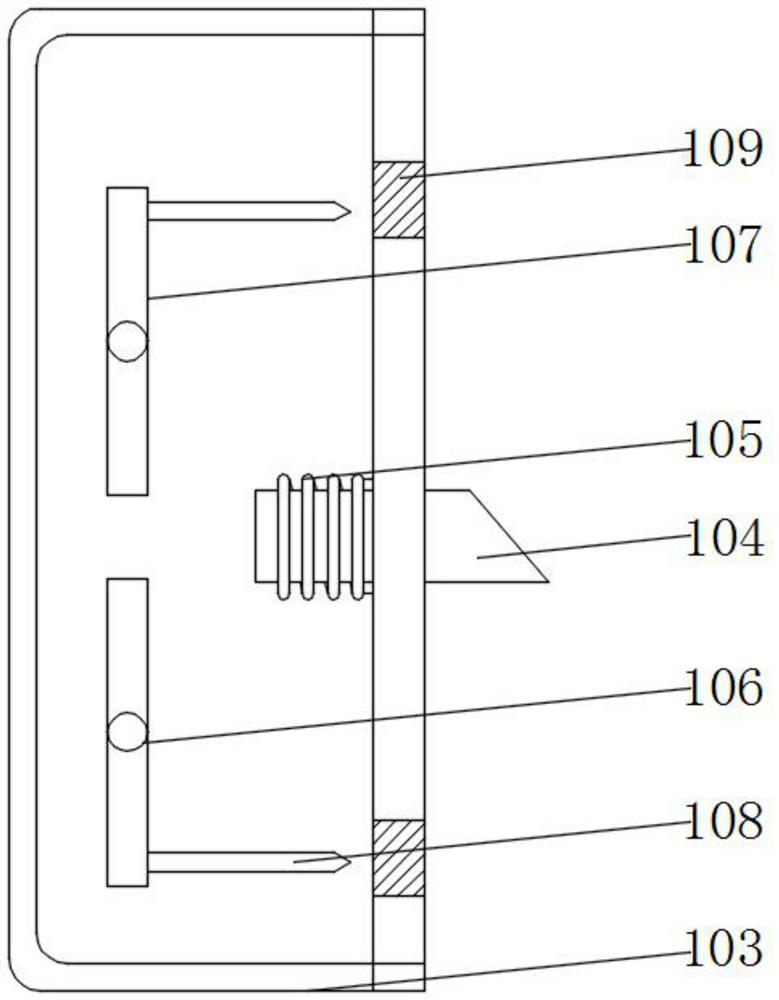

[0043] Example 2: See Figure 4 , Figure 5 , Figure 6 and Figure 7 , an embodiment provided by the present invention: a sliding bearing with a high-stability mounting support, an oil cup 201 is installed on the inner wall of the oil inlet hole 2, a sealing bolt 202 is installed on the outer wall of the oil cup 201, and the oil cup 201 The inner wall of the oil cup 201 is equipped with a sloping plate 203, the inner wall of the oil cup 201 is equipped with a filter screen 204, the bottom of the oil cup 201 is equipped with a roller 205, the top of the oil cup 201 is equipped with a cup cover 3, and the top of the sloping plate 203 is installed. A trigger 4 is installed on the inner top wall of the oil cup 201, a battery 301 is installed on the inner bottom wall of the cup cover 3, a buzzer 302 is installed on the inner wall of the cup cover 3, and a fixing frame 401 is installed on the inner wall of the trigger 4. The outer wall of the frame 401 is equipped with a rotatin...

Embodiment 3

[0044] Example 3: See Figure 8 and Figure 9, an embodiment provided by the present invention: a sliding bearing with a high-stability mounting support, an electric telescopic rod 601 is installed on the inner wall of the detector 6, and one end of the electric telescopic rod 601 extends into the inside of the bearing bush 110, The inner wall of the bearing bush 110 is provided with a fixed hole 602, the inner top wall and inner bottom wall of the fixed hole 602 are equipped with a movable plate 603, the outer wall of the movable plate 603 is equipped with a second spring 604, and one end of the second spring 604 is connected to the fixed hole. The inner wall of 602 is connected, one end of the electric telescopic rod 601 is installed with a test board 605, the inner wall of the test board 605 is installed with oil-absorbing cotton 606, the inner bottom wall of the test board 605 is installed with a pressure sensor 607, and the inner wall of the detector 6 is installed with t...

Embodiment 4

[0045] Example 4: See Figure 8 , an embodiment provided by the present invention: a sliding bearing with a high-stability mounting support, a heat dissipation fan 701 is installed on the inner wall of the radiator 7, a heat dissipation pipe 702 is installed on the inner wall of the radiator 7, and the heat dissipation pipe 702 One end of the shaft extends into the inside of the bearing housing 101 and contacts the outer wall of the bearing bush 110, the inner bottom wall of the radiator 7 is equipped with a motor 705, the output end of the motor 705 is equipped with a first bevel gear, and the inner top wall of the radiator 7 is installed with a reciprocating Screw mandrel 703, the bottom of reciprocating screw mandrel 703 is equipped with second bevel gear, and the outer wall of reciprocating screw mandrel 703 is equipped with a plurality of sealing blocks 704, when carrying out heat dissipation, first start motor 705, and the rotation of motor 705 drives the first bevel gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com