Smelting furnace for aluminum-titanium-boron wire production

An aluminum-titanium-boron wire, melting furnace technology, applied in furnaces, crucible furnaces, furnace components, etc., can solve the problems of increased coke ratio in the furnace, no coal powder injection, and inability to replace coke, etc., to reduce the coke ratio, The effect of improving the quality and improving the utilization rate of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

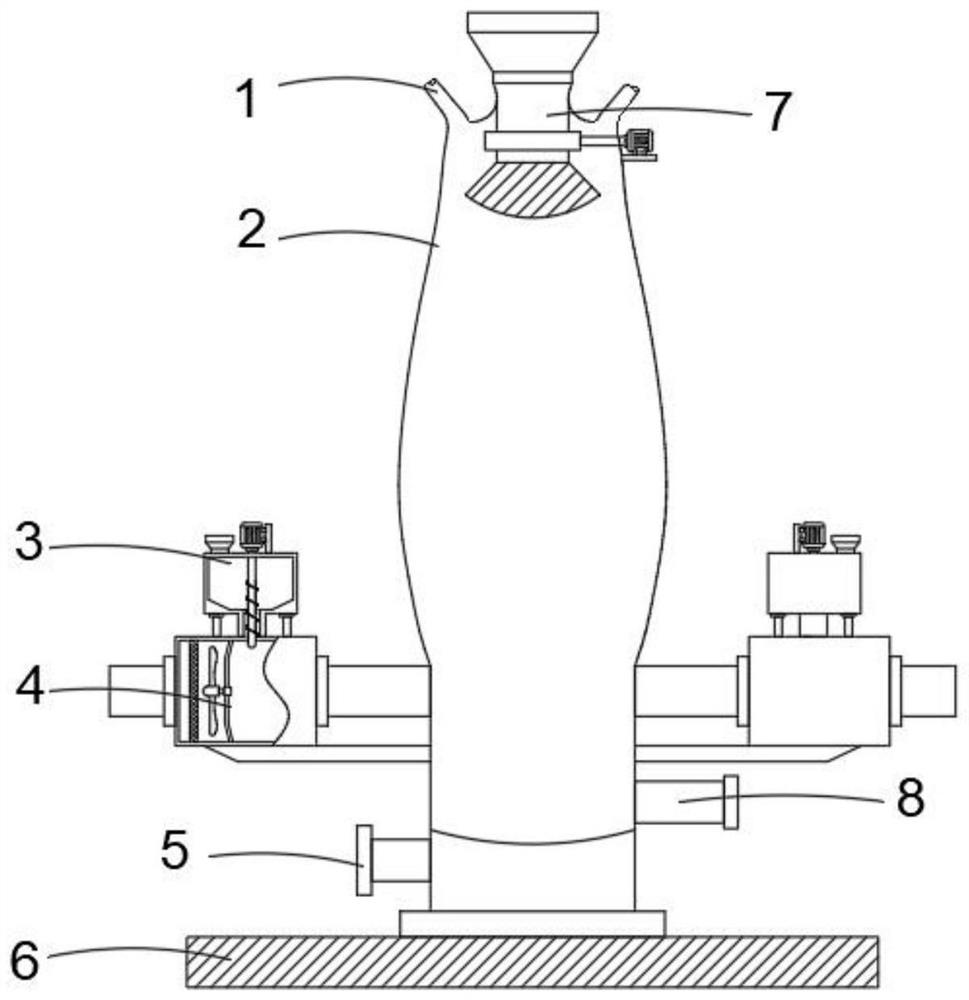

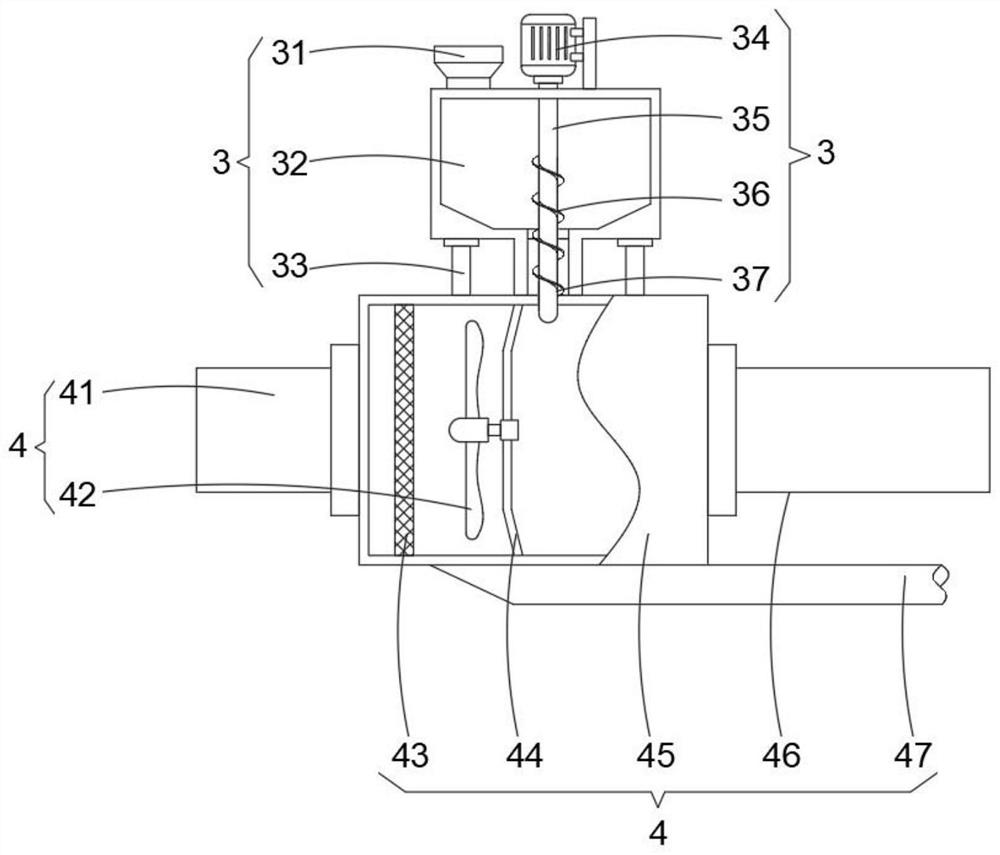

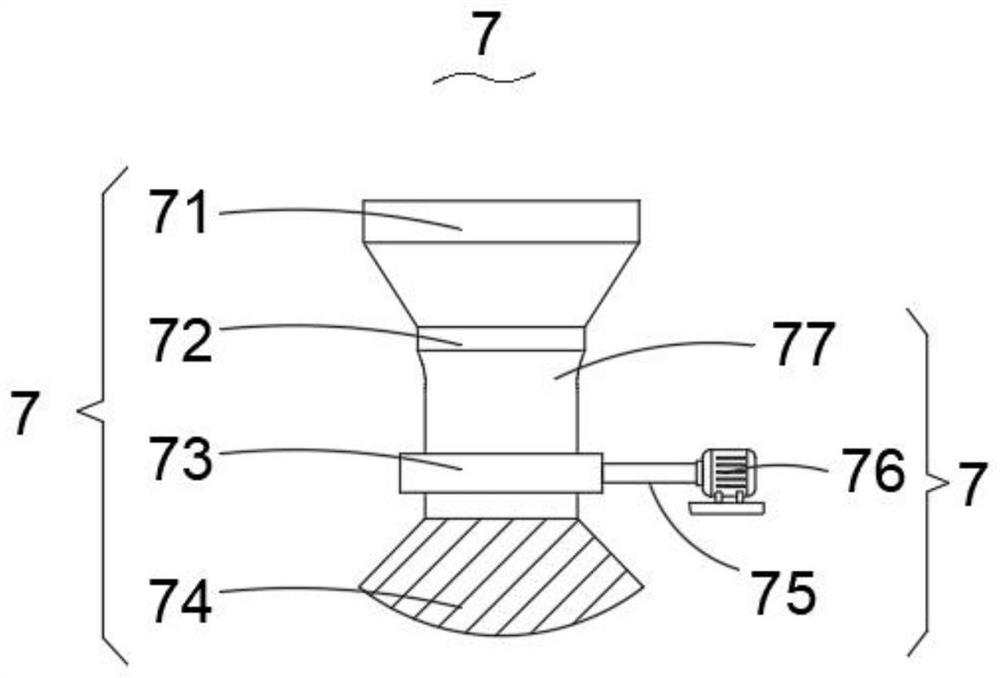

[0021] Please refer to figure 1 , figure 2 and image 3 The smelting furnace for the production of aluminum titanium boron wire includes: a blast furnace body 2, the top of the blast furnace body 2 is fixedly connected with two gas pipes 1 communicating with its interior, and the bottom of the blast furnace body 2 is fixedly connected with a gas pipe 1 communicating with its interior. Aluminum port 5 and slag discharge port 8; feeding mechanism 7, the top of the blast furnace body 2 is connected with a feeding mechanism 7 for feeding; air intake mechanism 4, the bottom of the blast furnace body 2 is connected with two symmetrical Air inlet mechanism 4; pulverized coal export mechanism 3, the quantity of described pulverized coal export mechanism 3 is two, and two pulverized coal export mechanisms 3 are respectively connected with the corresponding mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com