Digital fitting temperature compensation system of resistance-type differential pressure transmitter

A technology of temperature compensation and transmitter, which is applied in the direction of measuring fluid pressure by changing ohmic resistance, measuring fluid pressure through electromagnetic components, measuring fluid pressure, etc., can solve the problems of slow speed and poor consistency, and achieve low order, The effect of small amount of data and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

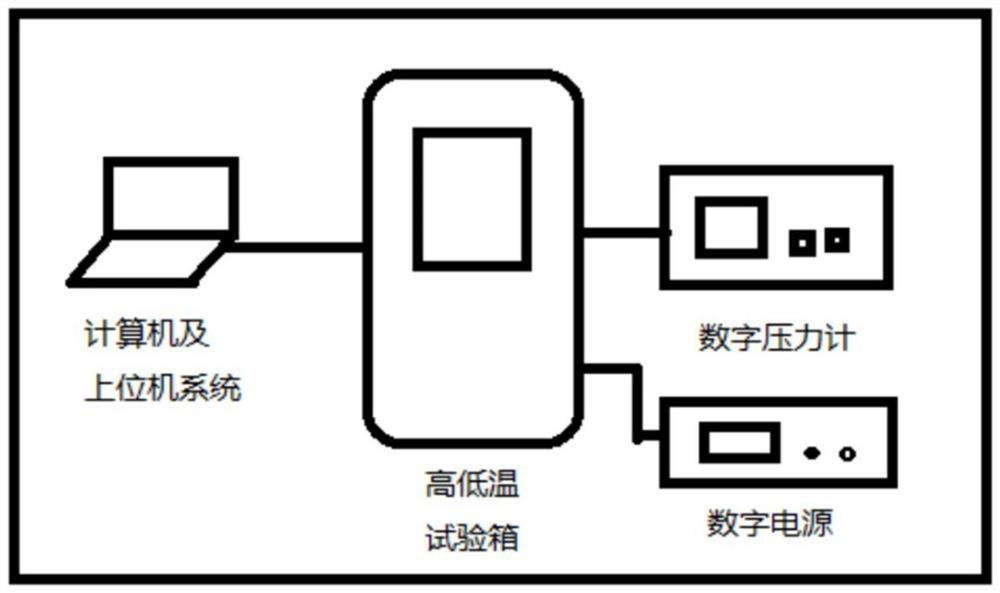

[0033] Such as figure 1 As shown, a schematic diagram of the digital fitting temperature compensation system of the resistive differential pressure transmitter of the present invention is given. The transmitter is connected to the computer system through a quick connector, and the digital power supply supplies power to the transmitter. The output value is collected.

[0034] The digital fitting temperature compensation system of the resistive differential pressure transmitter shown, including pressure transmitter and digital pressure gauge, digital power supply, high and low temperature test chamber, computer and upper computer system, digital communication equipment and other auxiliary components , digital pressure gauge, digital power supply, computer and upper computer system are all connected to the high and low temperature experiment box.

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com