Method for calculating ratio of fly ash to large slag based on mercury concentration measurement

A mercury concentration, fly ash technology, applied in the direction of measuring devices, fuel oil testing, instruments, etc., can solve the problems of reducing test uncertainty, reducing measurement work, unable to accurately measure ash and slag mass flow, etc., to eliminate measurement uncertainty big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

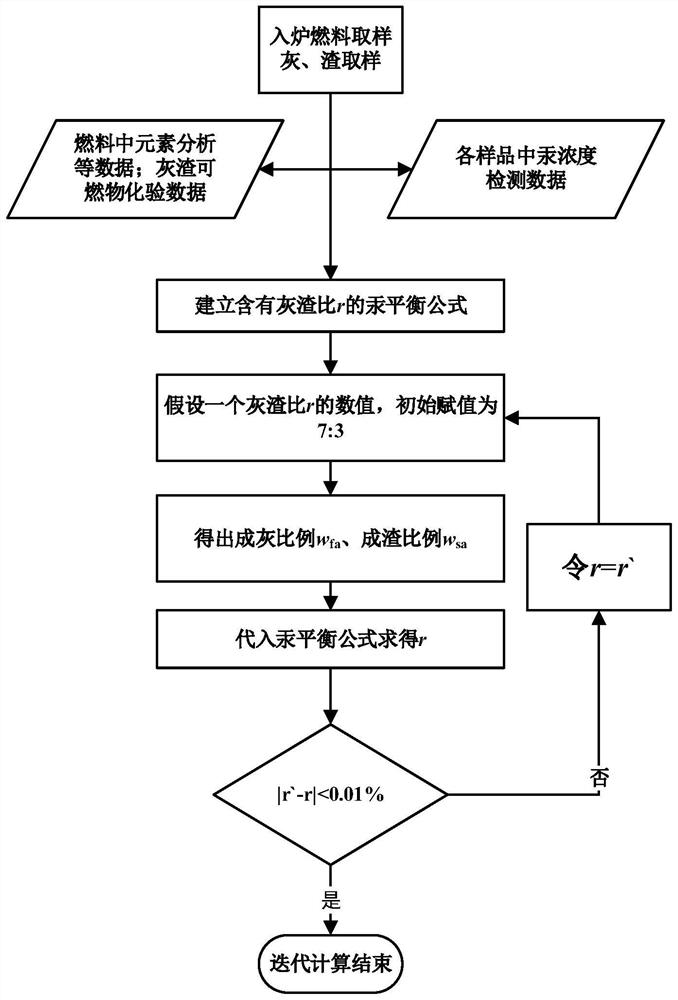

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0046] see figure 1 , a kind of method of calculating fly ash and large slag ratio based on mercury concentration measurement of the present invention, comprises the following steps:

[0047] According to the method stipulated in ASME PTC 4-2013 "Boiler Performance Test Regulations", the fuel, fly ash and bottom slag were sampled respectively;

[0048] Industrial analysis, elemental analysis and concentration of heavy metal mercury in fuel to analyze the fuel entering the boundary of the boiler using a mercury analyzer;

[0049] Use a mercury analyzer to analyze the mercury concentration in the fly ash and bottom slag leaving the boiler boundary;

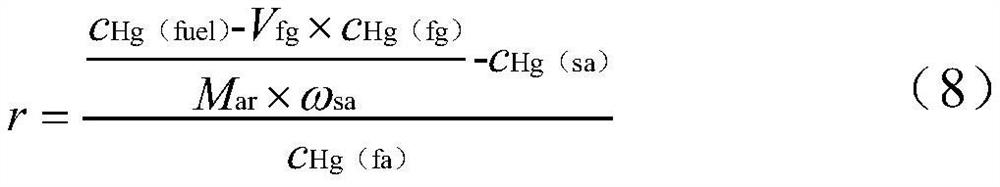

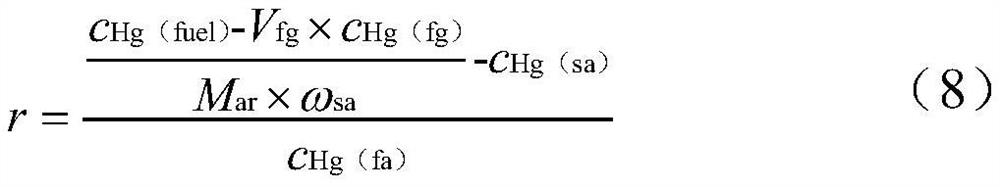

[0050] Among them, the basic formula for boiler mercury balance based on the conservation of mercury element is:

[0051] m Hg(fuel) =m Hg(fa) +m Hg(sa) +m Hg(fg) (1)

[0052] In the formula: m Hg(fuel) —...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com