Fuel cell adaptive control method and system based on power prediction

A fuel cell system, self-adaptive control technology, applied in fuel cells, forecasting, system integration technology, etc., can solve the problems of slow response to load changes, reduce power consumption and production costs, and low operating efficiency, and achieve improved load changes. The effect of response speed, reducing data dimension, and improving prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

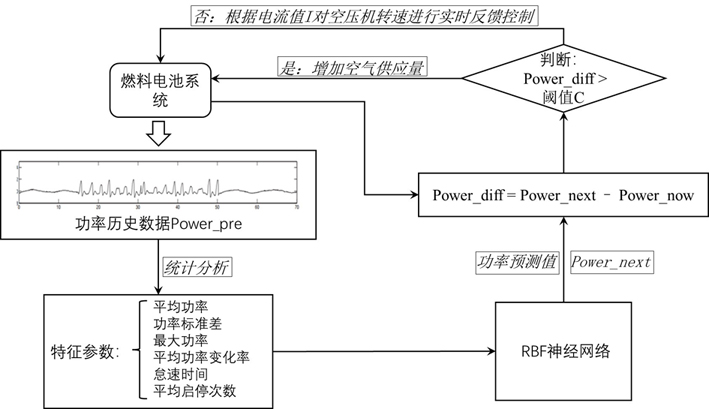

[0031] Such as figure 1 As shown, a fuel cell adaptive control method based on power prediction records the power curve in the last 70s in real time during the operation of the fuel cell system as historical data Power_pre. The real-time power value is Power_now.

[0032] Calculating the power prediction value Power_next of the fuel cell system according to the historical data Power_pre is divided into the following two steps.

[0033] 1) Statistically analyze the historical data Power_pre to obtain characteristic parameters such as average power, power standard deviation, maximum power, average power change rate, idle time, average start-stop times, etc., and form a characteristic parameter vector V, where the elements are V i Indicates that i represents the serial number of the characteristic parameter.

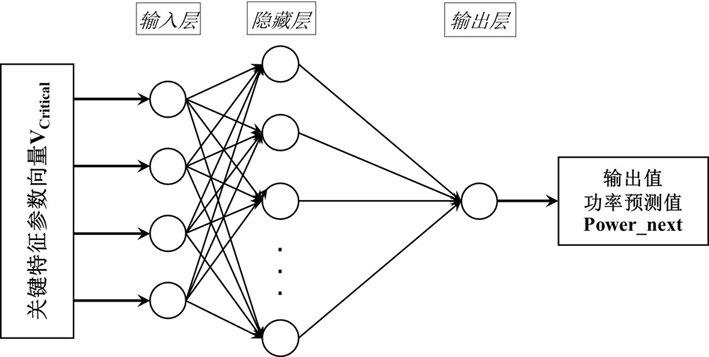

[0034] 2) Correlation analysis is performed on the historical data of the characteristic parameter vector V and the historical data of the output power, and the Pearson c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com