A method to optimize gas turbine igv control to improve the efficiency of gas-steam combined cycle

A combined cycle and gas turbine technology, applied in engine control, gas turbine installations, mechanical equipment, etc., can solve problems such as the inability of desuperheating water to control the temperature of the main steam, affecting the load capacity of the combined cycle unit, and reducing the efficiency of the unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] When it is close to the annual average working condition, readjust the IGV opening, control the exhaust temperature of the gas turbine and the main steam temperature of the turbine to the design value, and confirm the corresponding operating parameters to ensure the safe and stable operation of the unit.

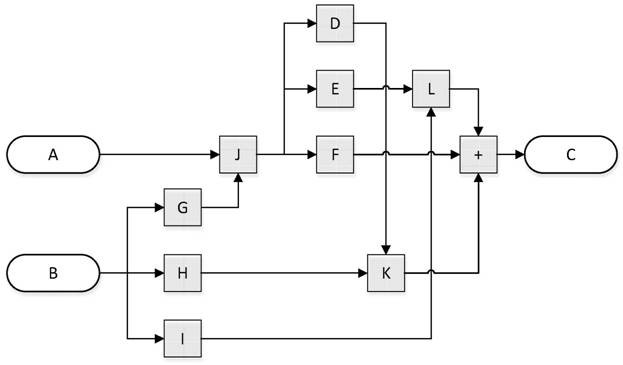

[0045] In the above scheme, first ensure that the inlet temperature of the compressor is close to the annual average temperature, then gradually increase the load of the gas turbine from 50% load, and adjust the IGV angle to control the exhaust temperature of the gas turbine and the main steam temperature of the turbine to the design value, and the IGV is obtained as The opening degree setting function "F" of gas turbine load changes, and finally closes the IGV by 0-5% when the gas turbine load is 50% to 90%.

Embodiment 2

[0047] When the temperature is directly lower than the annual average temperature, the deviation of IGV closing is added, and the corresponding operating parameters are confirmed at the same time, so as to improve the part-load operation efficiency of the unit.

[0048] In the above scheme, when the temperature is close to the annual minimum temperature, then the gas turbine load is gradually increased from 50%, and the IGV angle is adjusted to control the exhaust temperature of the gas turbine and the main steam temperature of the turbine to the design value, and the IGV with combustion Turn down the deviation function "D" of the load change, the IGV is turned down by 0 to -5% at 50% to 90% load, and the IGV deviation correction coefficient is taken as "1"; when the temperature gradually rises to the annual average temperature When the IGV is off, the IGV deviation correction coefficient is adjusted to control the exhaust gas temperature of the gas turbine and the main steam t...

Embodiment 3

[0050] When the temperature is higher than the annual average temperature, the deviation of IGV opening is added, and the corresponding operating parameters are confirmed at the same time, so as to prevent the gas turbine from entering the exhaust temperature control operation in advance under partial load.

[0051] In the above scheme, when the temperature is close to the annual maximum temperature, the gas turbine load is gradually increased from 50% of the load, and the IGV angle is adjusted to control the exhaust temperature of the gas turbine and the main steam temperature of the turbine to the design value, and the IGV changes with the gas turbine load. The opening deviation function "E" of 50% to 90% load increases the IGV by 0 to 5%, and takes the IGV deviation correction coefficient as "1"; when the temperature gradually decreases to the annual average temperature, adjust the IGV deviation The correction coefficient is to control the exhaust temperature of the gas turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com