Self-cooling drilling device for numerical control machine tool

A technology for drilling devices and CNC machine tools, which is applied to drilling/drilling equipment, components of boring machines/drilling machines, metal processing machinery parts, etc., and can solve problems such as interference between drill bits and workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

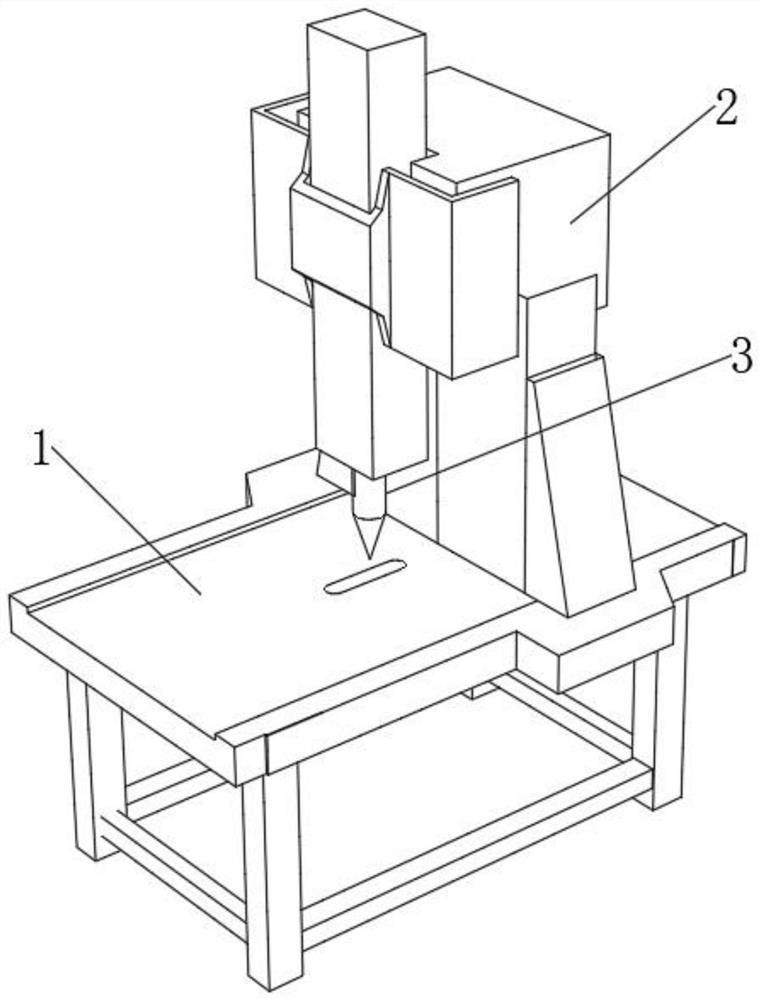

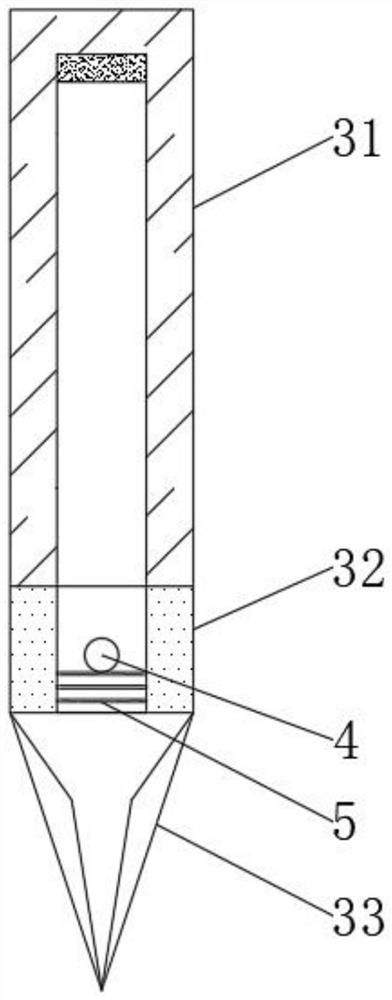

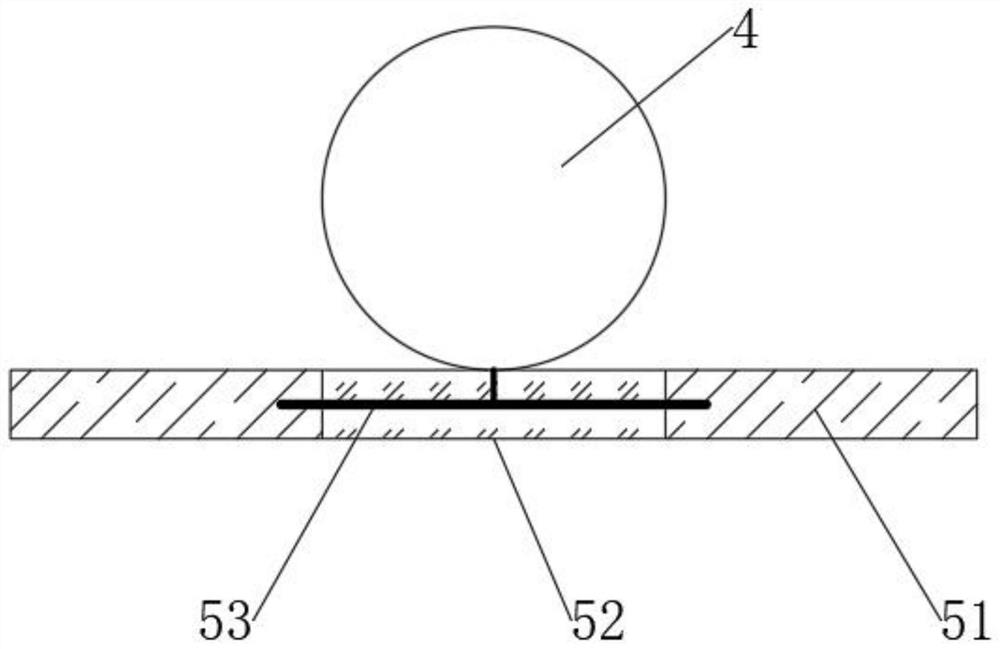

[0044] see Figure 1-2 , a self-cooling drilling device for a numerical control machine tool, comprising a machine tool body 1, a drilling machine 2 is installed on the machine tool body 1, a self-cooling drill 3 is installed on the drilling machine 2, and the self-cooling drill 3 sequentially includes from top to bottom The base part 31, the cooling part 32 and the working part 33, the cooling part 32 is connected with a plurality of evenly distributed water baffles 5, the top of the base part 31 is connected with a supplementary bag, the supplementary bag includes an iron plate and a plurality of cooling particles, and A number of cooling particles are attached to the lower surface of the iron plate. The cooling particles are made of saltpeter powder and magnetic powder. In normal conditions, the cooling particles can be attached to the iron plate with weak magnetic force. When the balloon 4 is triggered to float to the top, the strong magnet Under the action of the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com