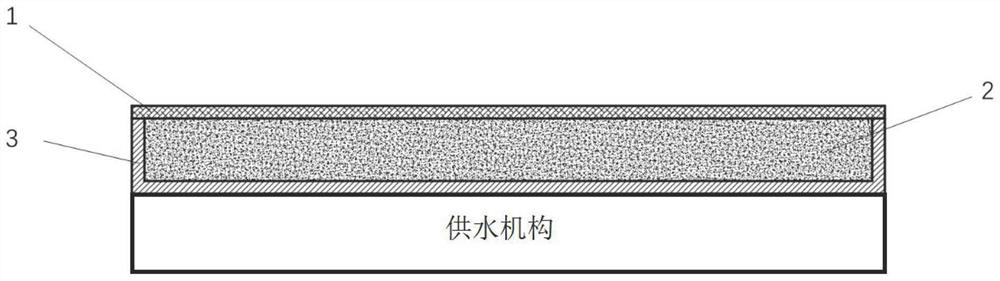

Hydrogel sweating and cooling system

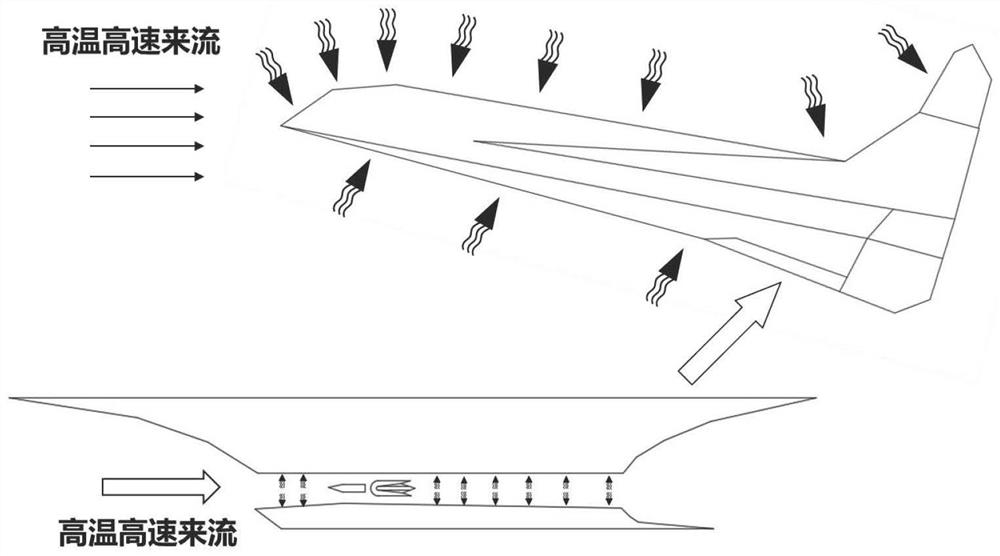

A technology of sweat cooling and hydrogel, which is applied in spaceflight vehicle heat protection devices, aerospace safety/emergency devices, weight reduction, etc., and can solve problems such as limited flow heat exchange efficiency, steam blockage, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

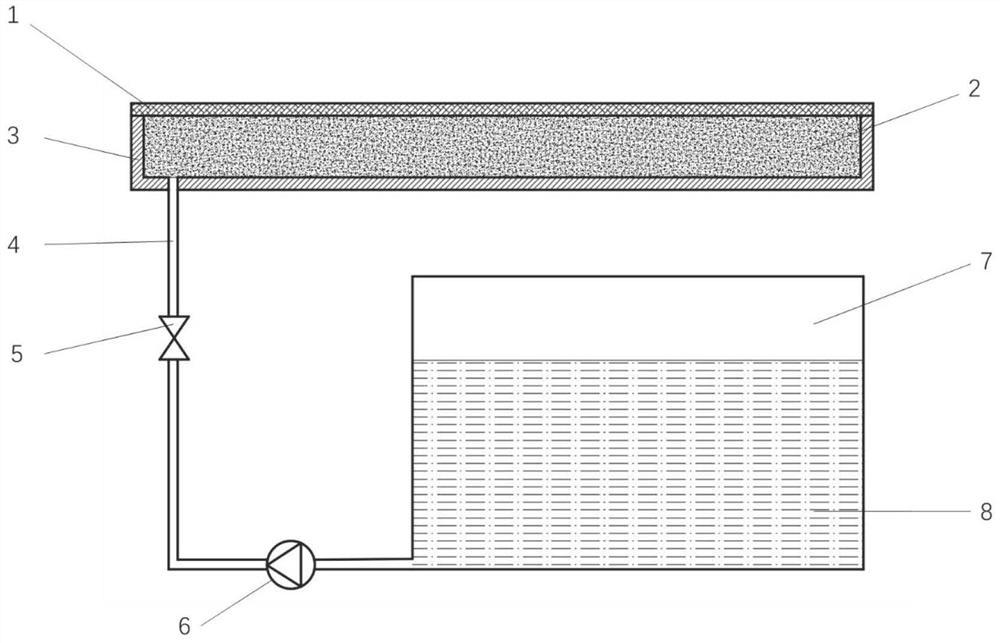

[0041] like image 3 As shown, the water supply mechanism in the first embodiment includes: a valve 5 , a pressure pump 6 and a water tank 7 .

[0042] The cavity mechanism is provided with a water injection port. The water injection port is connected to the water tank 7 through the pipeline 4 . The pipeline 4 is provided with a pressure pump 6 and a valve 5 . Based on this structure, the water pressure in the pipeline 4 is controlled by the water pump and the valve 5 , so that the water can be continuously input into the cavity mechanism and absorbed by the hydrogel coolant 2 .

Embodiment 2

[0044] like Figure 4 As shown, the water supply mechanism in the second embodiment includes: an air source 15 and a water tank 7 .

[0045] The cavity mechanism is provided with a water injection port. The water injection port is connected to the water tank 7 through the pipeline 4 . The air source 15 is connected with the water tank 7 through the pipeline 4 . Based on this structure, the hydrogel coolant 2 is connected to the water tank 7 through the pipeline 4, and the water tank 7 is pressurized by the air source 15 to maintain a certain pressure for water delivery.

Embodiment 3

[0048] The water supply mechanism includes: a water tank 7 .

[0049] The hydrogel coolant 2 is connected to the water tank 7 through the pipeline 4, and the water is transported and cooled by the natural suction of the water after the hydrogel coolant 2 loses water. At this time, there is no pressure pump or air source to provide water injection power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com