Precise hot forming method for deep-cavity ribbed notched irregular cylindrical forge piece

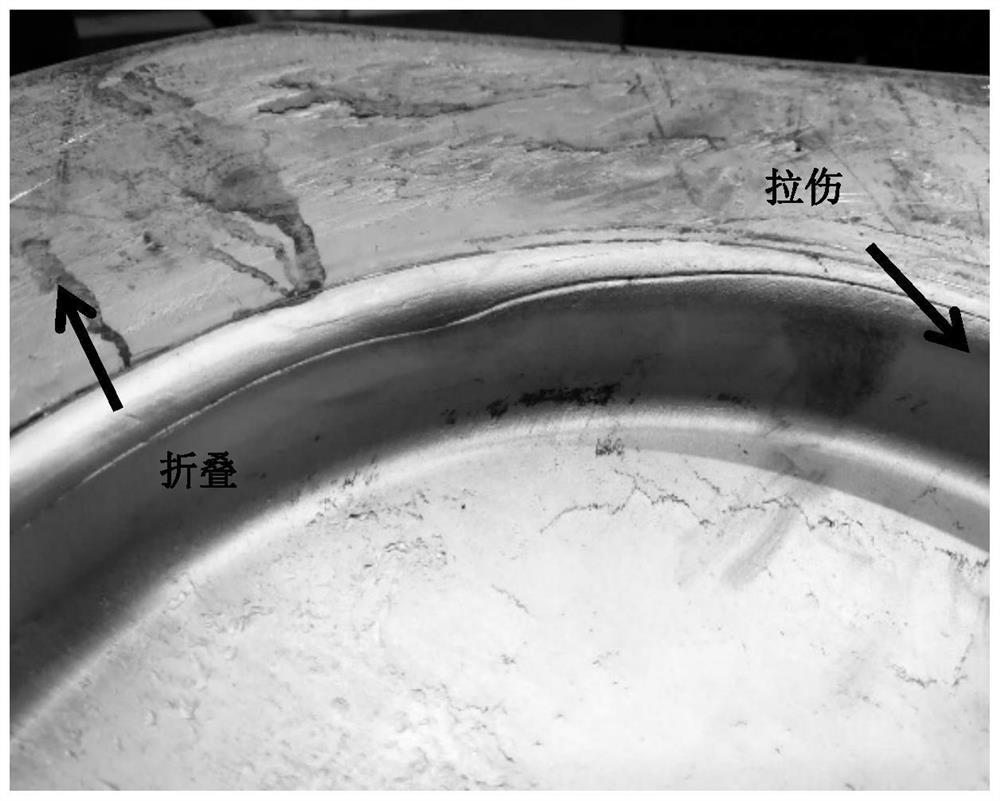

An irregular and hot forming technology, applied in the field of warm forging, can solve the problems of large load tonnage, surface strain on the rib side wall, low die life, etc., to reduce the forming load, reduce the forming energy consumption, and prolong the die life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Those of ordinary skill in the art can understand that the above-mentioned embodiments are specific examples for realizing the present invention, and in practical applications, various changes can be made to it in form and details without departing from the spirit and spirit of the present invention. scope.

[0045] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the spirit of the disclosure of the present invention will be described in detail below. After any person skilled in the art understands the embodiments of the present invention, they can learn from the present invention The techniques taught by the summary of the invention are subject to change and modification without departing from the spirit and scope of the summary of the invention.

[0046] The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com