Integrated automatic marking platform for teaching

An integrated, platform technology, applied in teaching models, educational appliances, instruments, etc., can solve problems such as inapplicability for on-site teaching and demonstration, large area, and inability to realize function splitting, etc., to ensure the depth of marking and marking. The accuracy of the marking position, avoiding pollution, and improving the product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

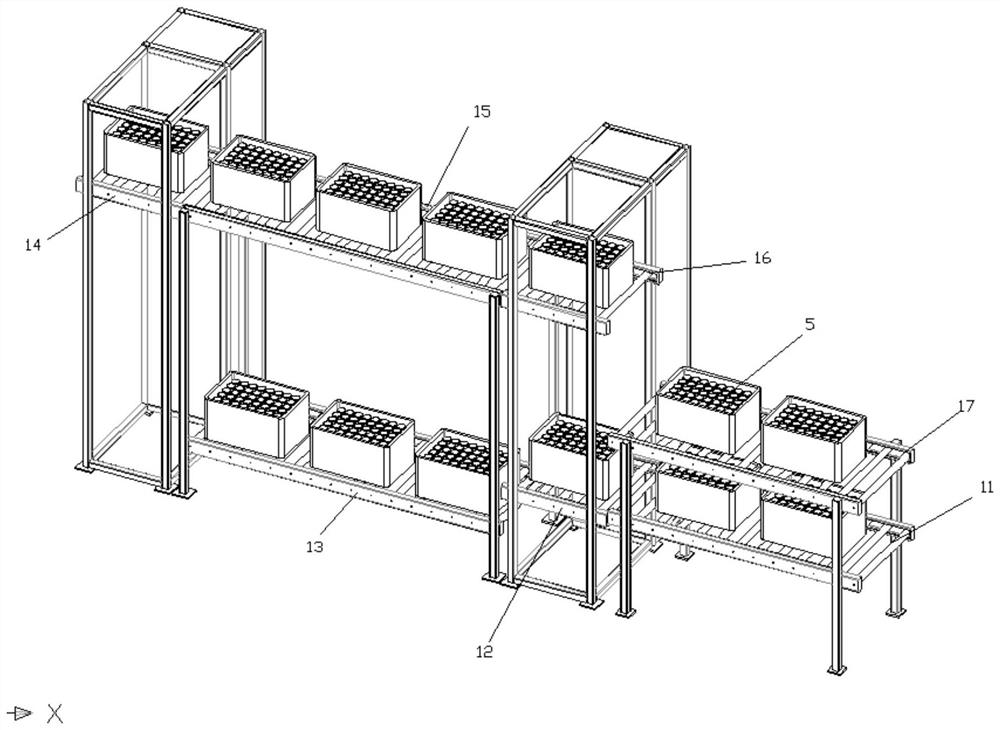

[0042] Such as Figure 1 to Figure 3 As shown, this embodiment designs a conveying demonstration mechanism 1, which can be independent from the demonstration process of the marking demonstration platform 3, and demonstrates the conveying process of the workpiece 5. The demonstration process summarizes the workpiece 5 in a matrix placed in a material box.

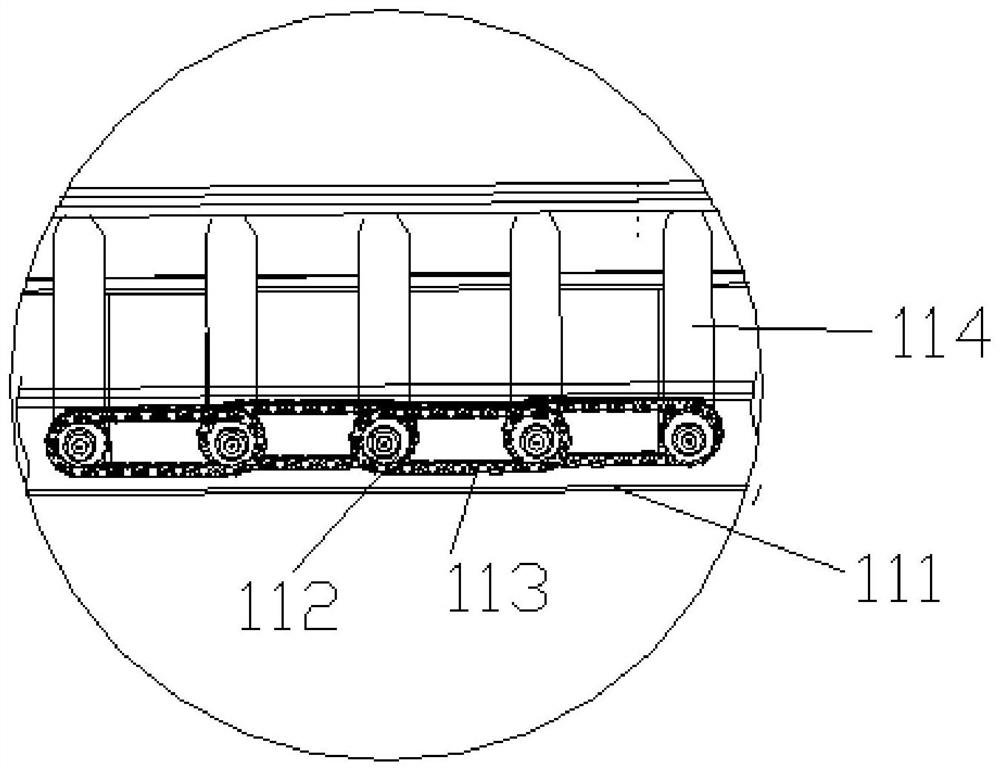

[0043] The conveying demonstration mechanism 1 includes a plurality of supports and a plurality of conveying lines, and each conveying line is respectively used for horizontally conveying material frames; the conveying function of each conveying line is independent of each other, and each conveying line includes two rod frames 111 and a plurality of Drive rollers 114; two rod frames 111 are parallel to each other, and each drive roller 114 is rotatably connected between the two rod frames 111, and each drive roller 114 is fixedly connected with two sprockets 112, between adjacent drive rollers 114 The space is connected wit...

Embodiment 2

[0052] Such as figure 1 and Figure 4 to Figure 6 As shown, a marking demonstration platform 3 is designed in this embodiment, which is used to demonstrate the marking process of the workpiece 5, including a machine platform 31, a shell cover 33, a rotary conveyor plate 34, a laser range finder 37, and a laser marking head 38. Structures such as visual detector 32, dust removal mechanism and two-way pneumatic clamp 35.

[0053] Machine platform 31 comprises support, lower platform 312 and upper platform 313, and lower platform 312 and upper platform 313 are all connected on the support, and upper platform 313 is positioned at the top of lower platform 312, and the middle part of upper platform 313 is provided with accommodating rotary conveying The hole of the disc 34 , the driving mechanism is fixed on the lower platform 312 and is used to connect and support the rotary conveying disc 34 . The bracket is a frame structure welded by square tubes.

[0054] The shell cover 33...

Embodiment 3

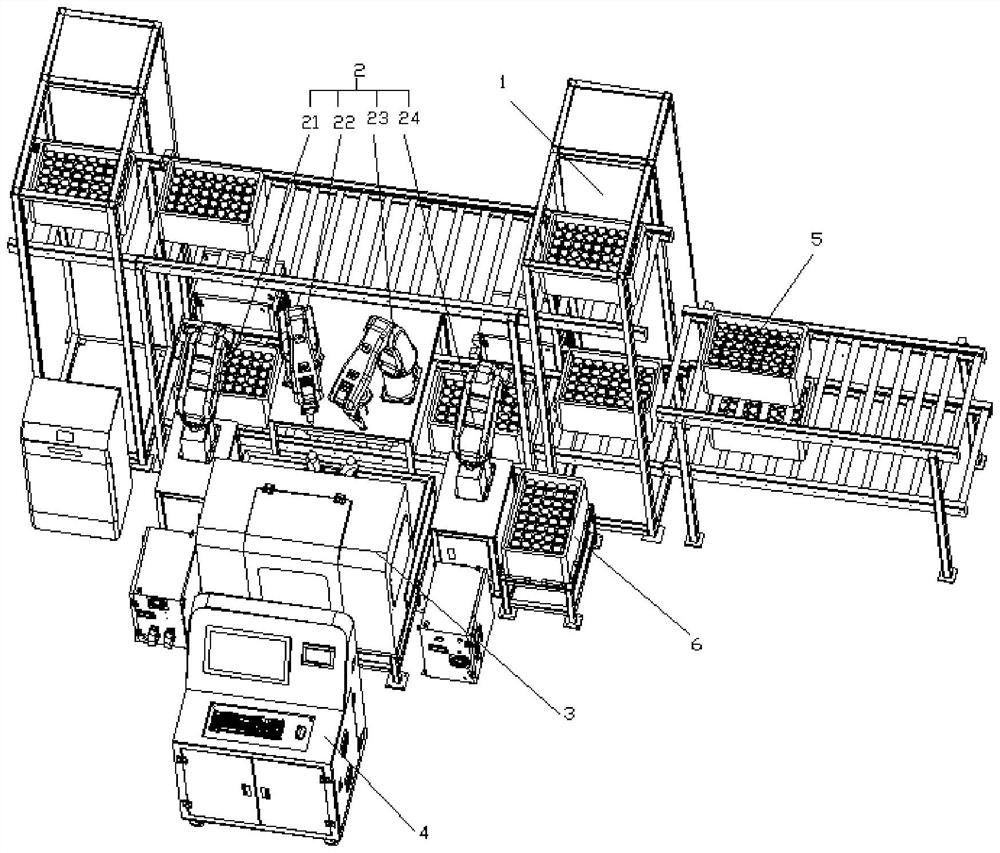

[0063] Such as Figure 1 to Figure 6 As shown, this embodiment designs an integrated automatic marking platform for teaching, including the conveying demonstration mechanism 1 described in Embodiment 1, the marking demonstration platform 3 described in Embodiment 2, and the manipulator 2. Product box 6 and console 4. The manipulator 2 is used to realize the transfer of the workpiece 5 between the conveying demonstration mechanism 1 and the marking demonstration table 3 .

[0064]A manipulator 2 is set at each of the four pick-and-place stations, and the unqualified product frame 6 is located at a pick-and-place station and is located on the right side of the marking demonstration table 3, and the manipulator 2 at this station can grab and put the workpiece 5 back On the station conveying line 13 or catch and move in the unqualified product frame 6. The mechanical claws include a first mechanical gripper 21, a second mechanical gripper 22, a third mechanical gripper 23 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com