Low-impact high-reliability counterweight type automatic explosive pressing device for initiating explosive device

A low-impact, pyrotechnic technology, applied in ignition devices, explosives, explosives processing equipment, etc., can solve the problems of low production efficiency, large impact of pressing charges, inability to adapt to high reliability and high efficiency of pyrotechnics pressing charges, etc. Reliable force transmission, improved drug pressing efficiency and manual safety, and stable and reliable pressing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

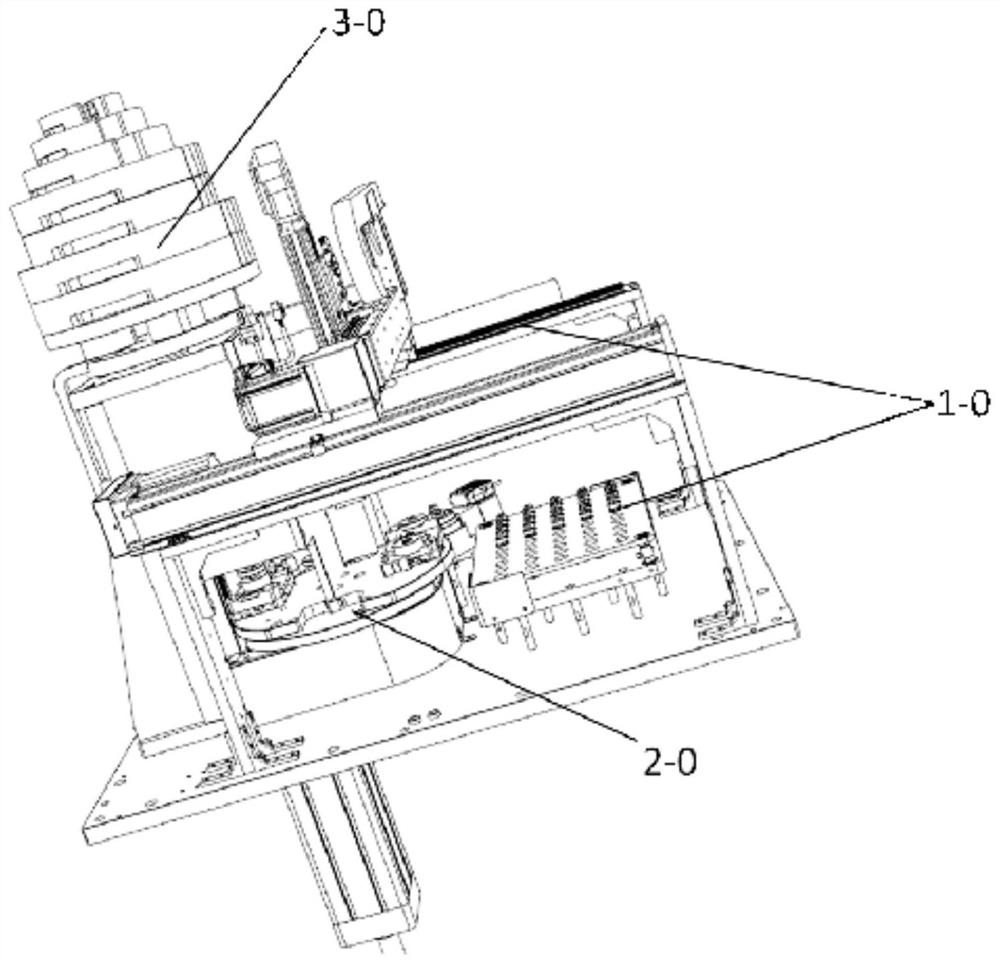

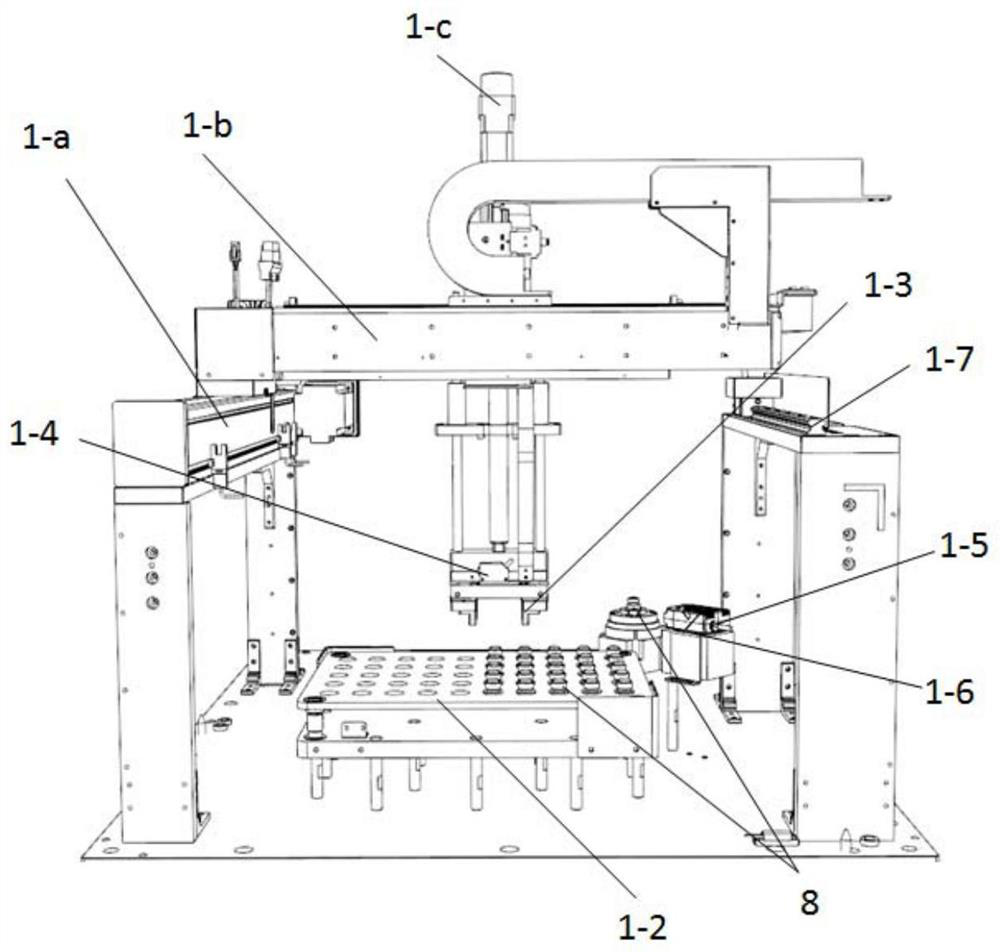

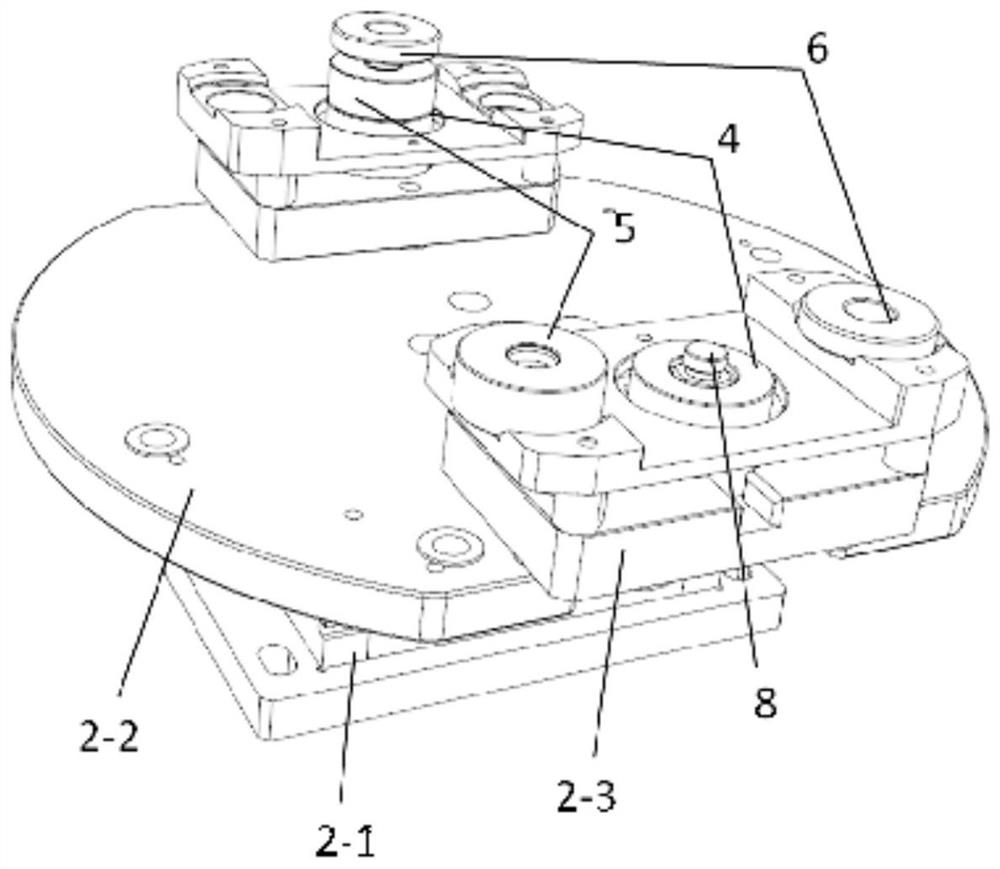

[0057]The invention includes a loading and unloading module, a turntable module, a press module, a PLC control module, a man-machine interface module, a gateway module and the like. Loading and unloading module: 2-axis: 2-axis servo (X / Y), 1-axis stepping (Z), gripper mechanism and QR code scanning gun constitute the loading and unloading module, which can realize the specified position to clamp the product through the 3-axis motor Transport to the designated location to place the product, the positioning accuracy is 0.003mm, which can meet the precise positioning requirements of product transport, the cylinder jaws clamp the product to be pressed to the scanning station, and the station rotates through the stepping motor to complete the scanning of the code scanning gun. The gripper puts the scanned product into the center of the turntable module. Turntable module: The turntable module is an intermediate module connecting the loading and unloading module and the press module....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com