Tyre steel wires and curtain thread tension sensor

A tension sensor and steel cord technology, which is applied in the sensor field to achieve the effects of good temperature resistance, reliable force transmission and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

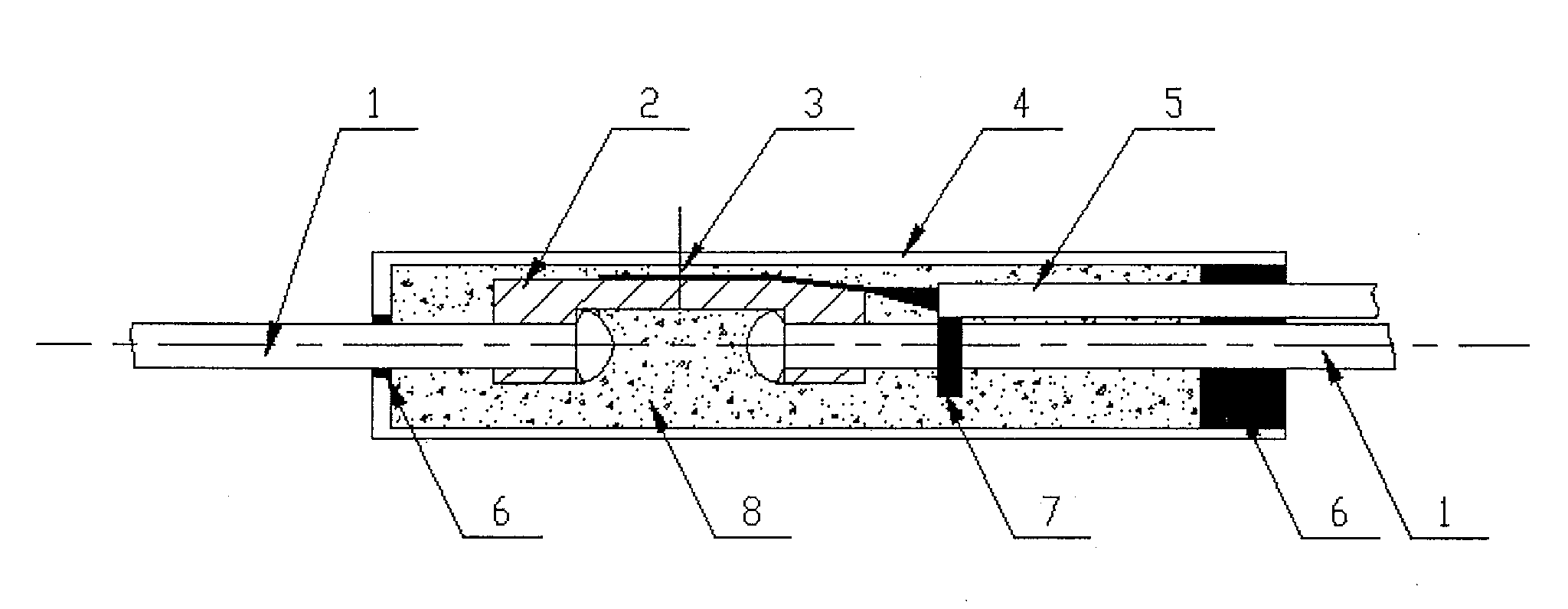

[0020] like figure 1 As shown, for the steel cord tension sensor in this embodiment, the steel cords (1) at both ends are straightened and pressed into the cord layer parallel to the alignment direction of the steel cords to be embedded in the cord layer during tire molding, and the steel sleeve (4 ) at the position of the test point, hinge off the excess steel cord (1) whose length exceeds the width of the ply at both ends, do not press the lead wire (5) on the steel cord (1), and arrange the lead wire (5) between the ply and the Between the rubber, along the direction between the layers, it leads out of the tire from the tire shoulder. After vulcanization, test the output signal of the sensor and clear the bit if the output value is normal. For preventing that whole position is damaged in tire manufacturing process, be full of soft rubber (8) between this steel sleeve (4) and elastic beam (2), steel sleeve (4) two ends outlets are sealed with epoxy resin (6). In order to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com