Carburizing and quenching process for thin-wall gear

A carburizing quenching and gear technology, applied in metal material coating process, manufacturing tools, coatings, etc., can solve the problems of large elliptical deformation and warping deformation, deformation, and difficult process, and reduce elliptical deformation and warping. warp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057]1) Prepare thin-walled gear blanks, the requirements are as follows

[0058] Material: 20CrMnTi

[0059] Surface hardness: 156-207HB

[0060] Grain size grade: ≥6

[0061] Banded tissue grade: ≤2 grades

[0062] 2) After the thin-walled gear blank has been shaped, it is tempered at 180°C ± 5°C for 2 hours in a trolley resistance furnace, and then air-cooled to room temperature after being released from the furnace;

[0063] 3) After the thin-walled gear is finished turning and drilling to the pre-heating state, use the tempering furnace on the multi-purpose furnace production line to perform pre-oxidation treatment at 400°C±5°C for 90 minutes. After the pre-oxidation is completed, it will enter the heating furnace of the multi-purpose furnace production line with temperature ;

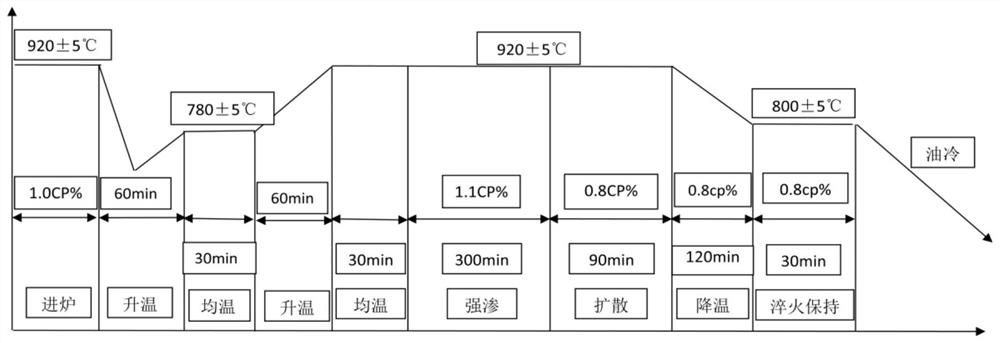

[0064] 4) After the thin-walled gear enters the heating chamber of the multi-purpose furnace production line, press figure 1 The process shown is carburizing:

[0065] 41) Heat up for 1 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com