Full-automatic intelligent oven door

An oven door, fully automatic technology, applied in the field of ovens, can solve problems such as high work intensity, high temperature gas injury, safety accidents, etc., to reduce work intensity and avoid injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

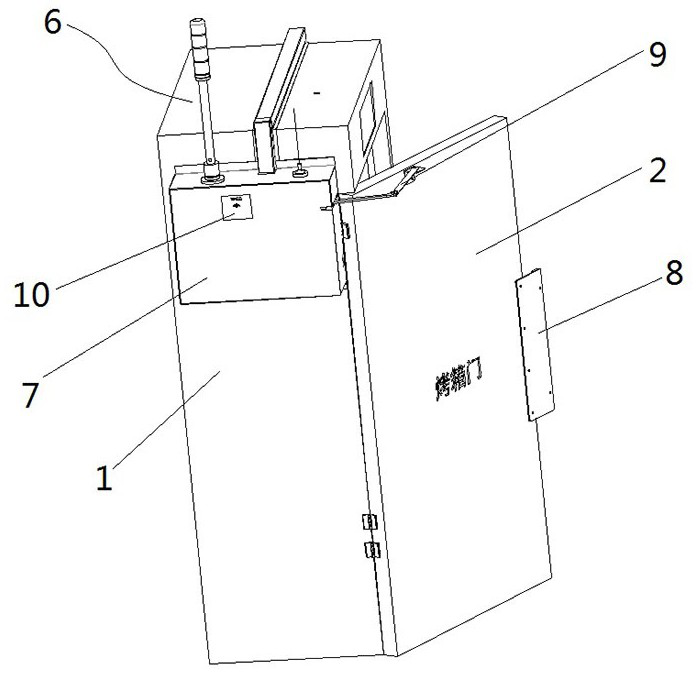

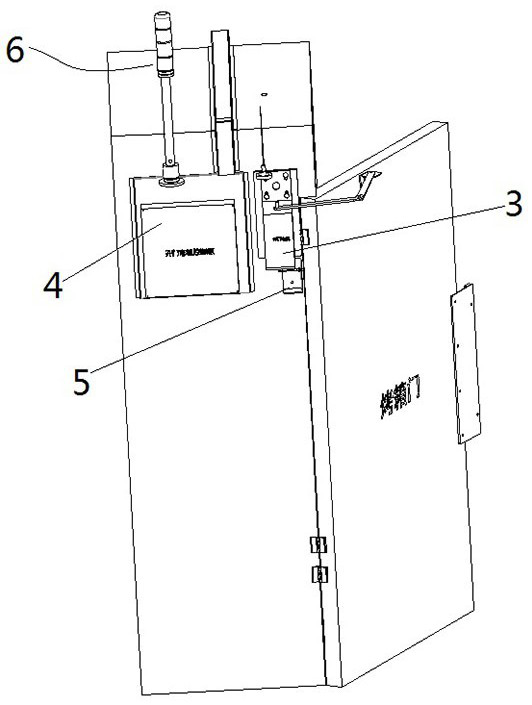

[0019] The first embodiment: a fully automatic intelligent oven door, including a door panel 2 for rotating connection with the oven 1, and also includes a door opening motor 3 for being installed on the oven 1 and located on the side of the door panel 2, the door opening The motor 3 is connected to the door panel 2 through the crank arm structure 9, and the fully automatic intelligent oven door also includes an electric control module 4 for controlling the start and stop of the door opening motor 3, and the electric control module 4 is connected to the control module of the oven 1 by signal, When the control module gives a signal that the door panel 2 can be opened, the door opening motor 3 is controlled to start, and the crank arm structure 9 drives the door panel 2 to open.

[0020] It includes a proximity switch 5 arranged on the oven 1 and located beside the door panel 2 for judging whether the opening angle of the door panel 2 meets the standard, and the proximity switch ...

no. 2 example

[0030] The difference between this embodiment and the first embodiment is that the alarm device is only one of the alarm lamp or the buzzer alarm, instead of both.

no. 3 example

[0032] The difference between this embodiment and the first embodiment is that no integrated box is provided, and each component can be arranged at each position on the oven.

[0033] In the present invention, unless otherwise specified and limited, for example, it can be fixed connection, detachable connection, or integrated; it can be mechanical connection or electrical connection; it can be direct connection or The indirect connection through an intermediary can be the internal communication of two elements or the interaction relationship between two elements. Unless otherwise clearly defined, those of ordinary skill in the art can understand the above terms in the present invention according to the specific situation. specific meaning in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com