Automatically-controlled current-driven test device for electrically-controlled shock absorber

A technology of current drive and test device, applied in the direction of measuring device, instrument, measuring electricity, etc., can solve the problems of large current fluctuation, slow signal response and poor stability of electronically controlled shock absorber, achieve timely power supply, improve efficiency, use safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

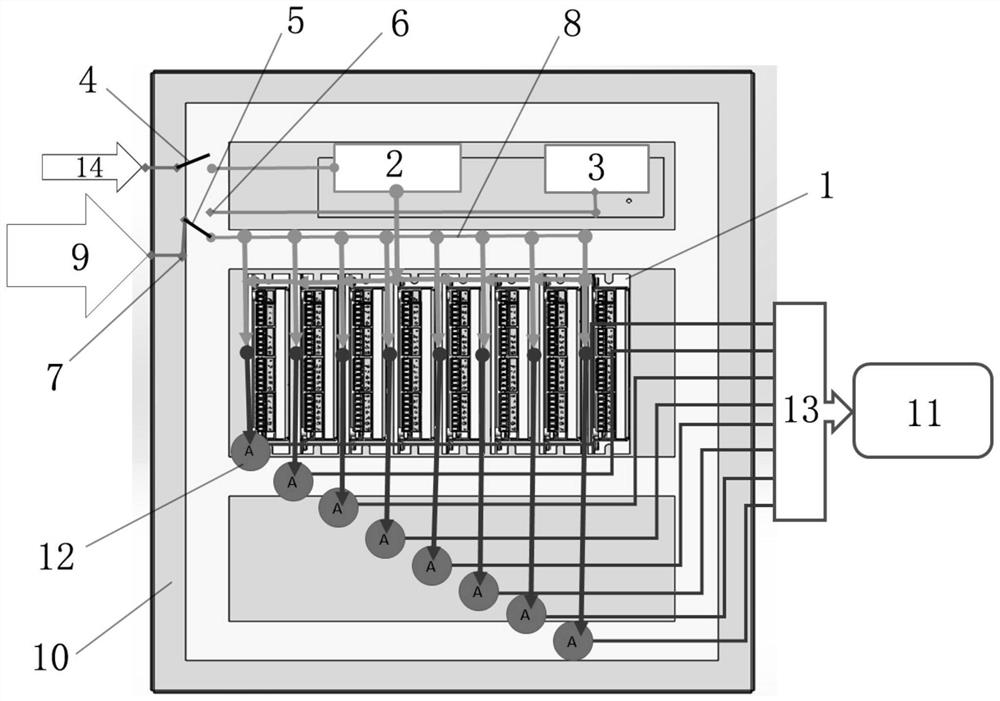

[0024] Embodiment 1: Voltage automatic control state, as attached figure 1 As shown, a kind of automatically controlled electronically controlled shock absorber current drive test device includes a box body 10, a power supply system and a current drive system are arranged in the box body 10, and the current drive system has eight current drivers 1, and the power supply system The system includes a power supply 2 and a voltage simulator 3, one end of the power supply 2 is electrically connected to the power switch 4 provided on the box 10, and the other end of the power supply 2 is electrically connected to each current driver 1 of the current drive system to realize power supply The power switch 4 is connected with the external AC circuit 14, and controls the power supply of the power supply 2; the gear switch 5 is located between the power supply system and the current drive system, and one end of the gear switch 5 is electrically connected with the voltage signal channel 8, a...

Embodiment 2

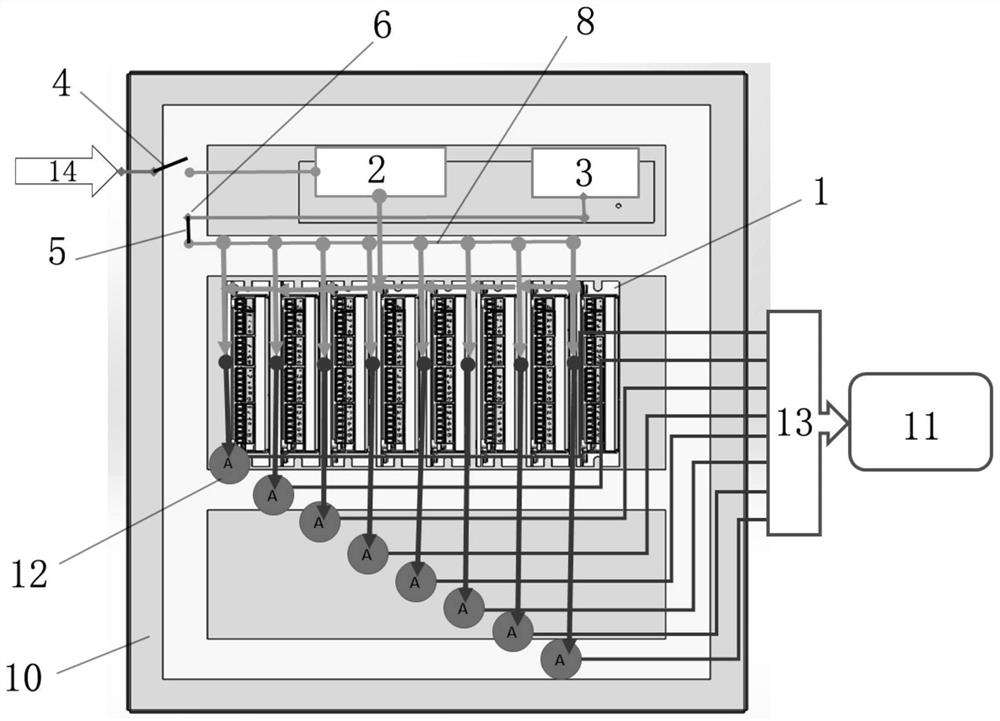

[0028] Example 2: Voltage manual control state, as attached figure 2 As shown, a kind of automatically controlled electronically controlled shock absorber current drive test device includes a box body 10, a power supply system and a current drive system are arranged in the box body 10, and the current drive system has eight current drivers 1, and the power supply system The system includes a power supply 2 and a voltage simulator 3, one end of the power supply 2 is electrically connected to the power switch 4 provided on the box 10, and the other end of the power supply 2 is electrically connected to each current driver 1 of the current drive system to realize power supply The power switch 4 is connected with the external AC circuit 14, and controls the power supply of the power supply 2; the gear switch 5 is located between the power supply system and the current drive system, and one end of the gear switch 5 is electrically connected with the voltage signal channel 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com