Transformer voltage regulating lead wire assembling method

A technology of voltage regulating lead and assembly method, which is applied in the field of transformers, can solve the problems of time-consuming and laborious assembly of voltage regulating leads, and achieve the effects of saving lead wire assembly time, large operating space, and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

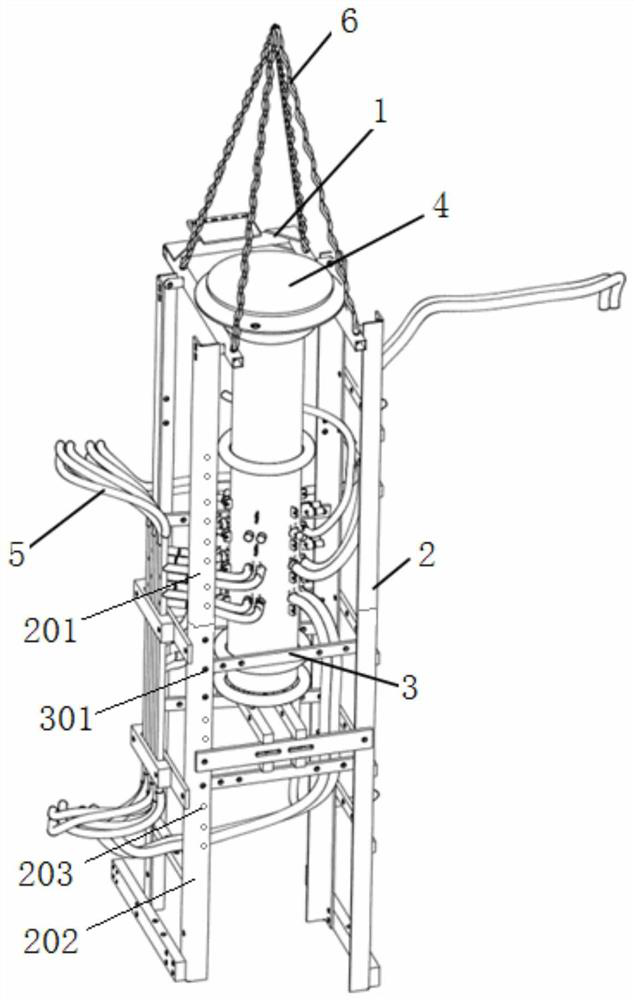

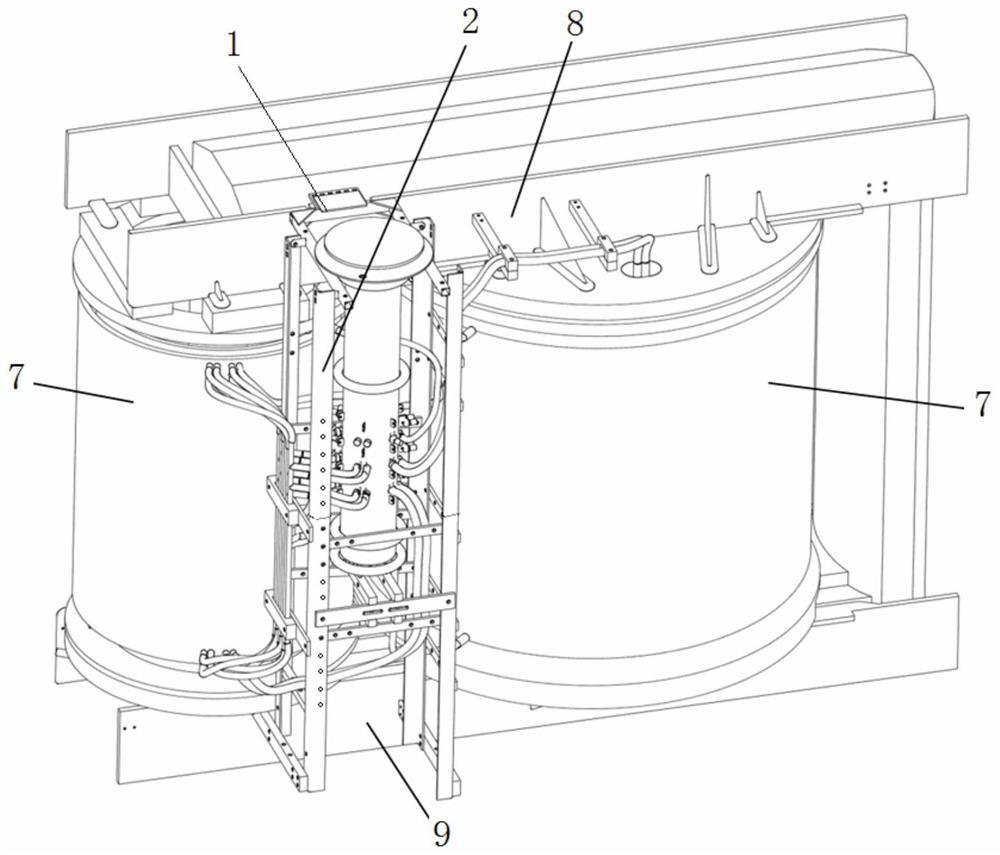

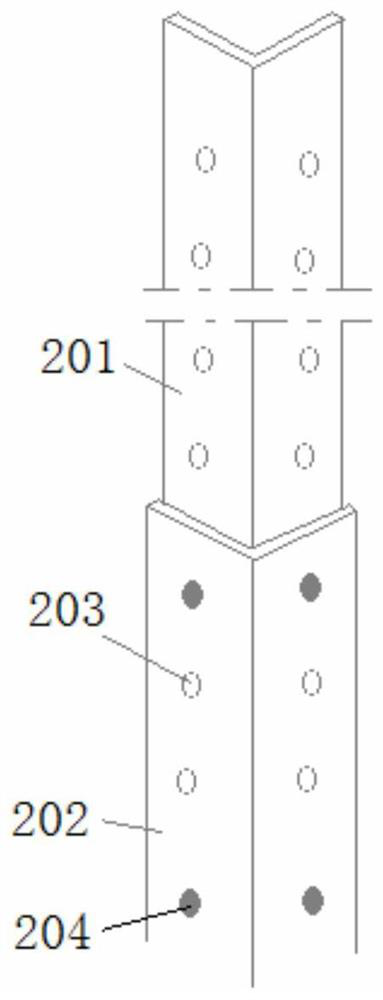

[0027] like Figure 1~3 As shown, the present invention includes a switch support plate 1, a vertical pole 2 and a cross bar 3, wherein the vertical pole 2 is arranged vertically and its upper end is fixedly connected with the switch support plate 1, and the cross bar 3 is arranged horizontally and between two adjacent poles 2 The crossbar 3 and the vertical pole 2 form a frame structure, the upper end of the tap changer 4 is installed on the switch support plate 1, and the body of the tap changer 4 is placed in the frame. After the pressure lead wire 5 is connected to the joint on the tap switch 4, it is bandaged and insulated, and the joint is reserved. The voltage regulation lead wire 5 can be bound on the frame, so that the tap changer 4, the frame and the voltage regulation lead wire 5 can pass through the suspension together. Rope 6 overall hoisting, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com