Cooling device for reducing lead refining in secondary lead smelting

A secondary lead smelting and cooling device technology, applied in the field of cooling devices, can solve the problems affecting the health of workers, the inability to recycle water, and the waste of water resources, etc., to achieve efficient and intelligent use of water resources, prolong service life, and save water resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

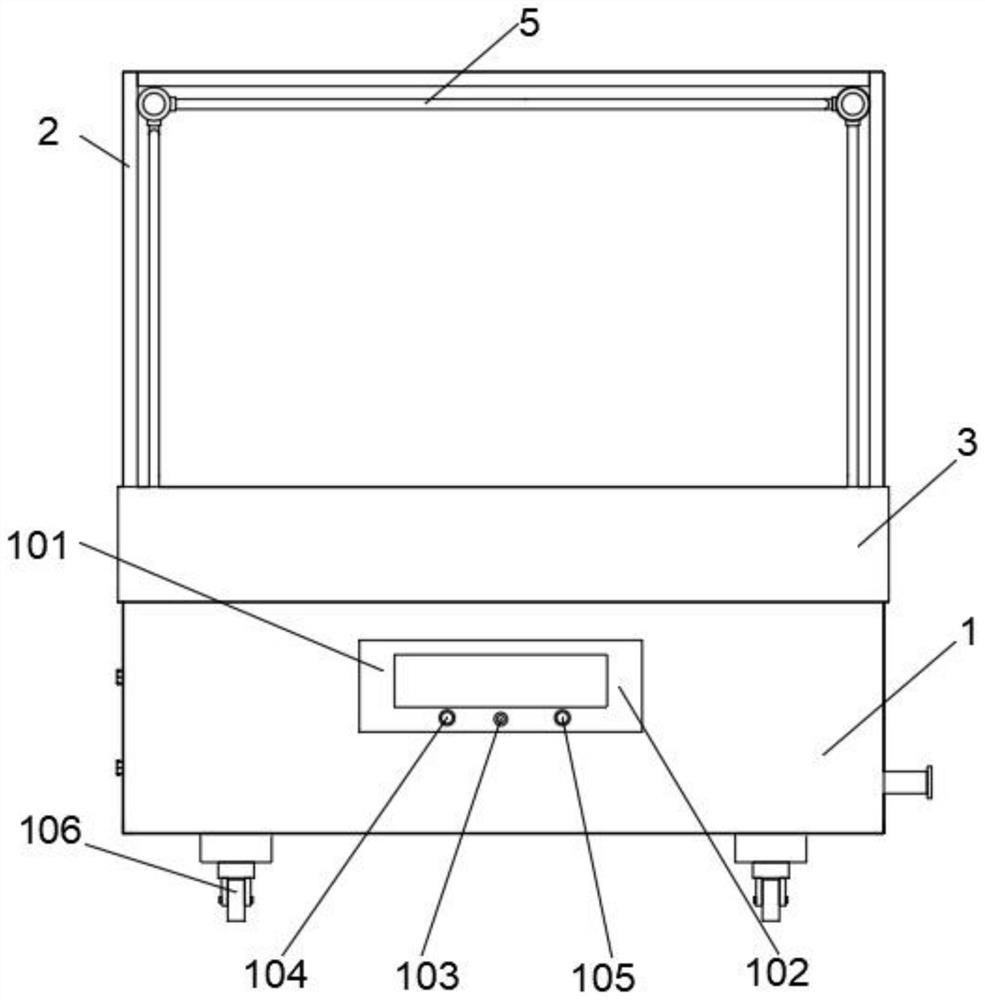

[0024] Such as figure 1 - Figure 4 As shown, a cooling device for secondary lead smelting and reduction lead refining includes a housing 1, a control panel 101, a display screen 102, a start button 103, an indicator light 104, a warning light 105 and a moving wheel 106. The control panel 101 is installed in the housing One side of the body 1, the display screen 102, the start button 103, the indicator light 104 and the warning light 105 are all electrically connected with the control panel 101, the indicator light 104 and the warning light 105 are respectively arranged on both sides of the start button 103, and the moving wheel 106 is set There are four, and the moving wheels 106 are installed at the four corners of the bottom surface of the housing 1, press the start button 103 to start the equipment, the display screen 102 is used to display the total water consumption and water pressure, and the control panel 101 is used to control the components Working, the indicator li...

Embodiment 2

[0028] The circulating water distribution cooling system is replenished by regularly opening the water inlet replenishment valve 508, and the problem of unstable water pressure is solved to a certain extent. High, but when the water inlet replenishment valve 508 needs to be closed, the water pressure will decrease again, thus causing the water pressure to be unstable, resulting in the problem of uneven cooling effect and low cooling efficiency;

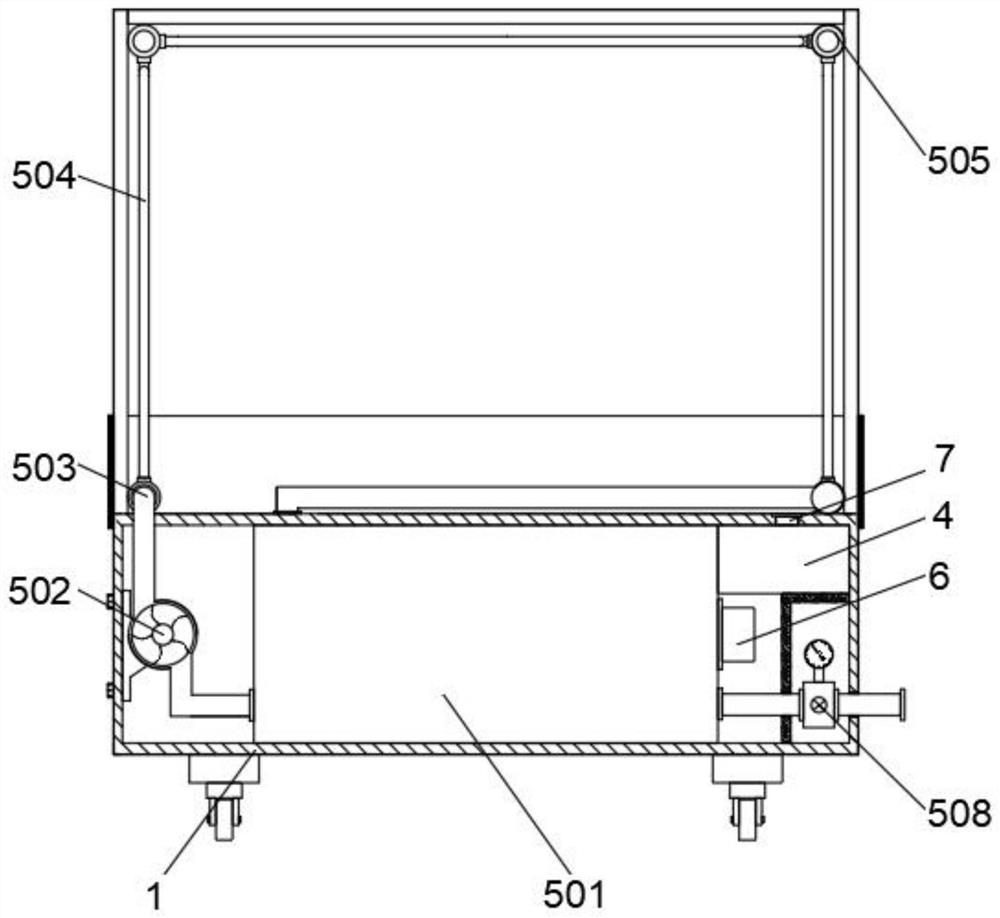

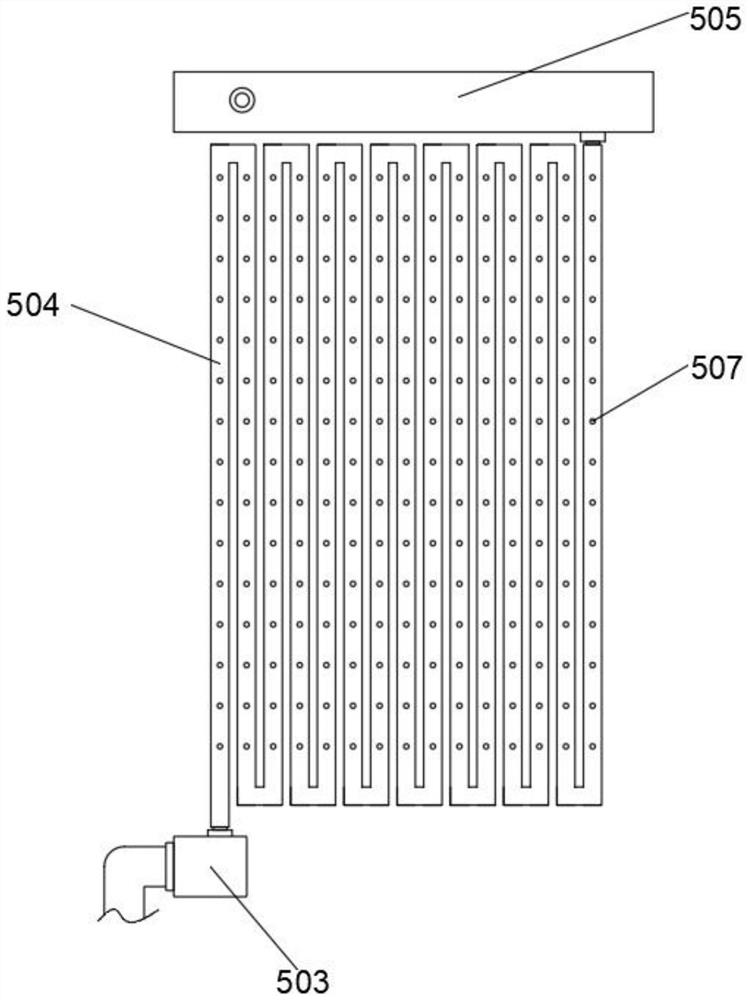

[0029] Such as figure 2 , Figure 5 with Image 6 As shown, a cooling device for secondary lead smelting and reduction lead refining also includes a micro-pressure control water assembly 6, which is adapted to the circulating water distribution structure 5, and the micro-pressure control water assembly 6 is installed on the circulating cloth In the circulating water tank 501 of the water replenishment structure 5, the micro-pressure control water component 6 is used for constant circulating water distribution water pressure;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com