Optical glass forming mold device

A technology for molding molds and optical glass, applied in glass molding, glass pressing, glass manufacturing equipment, etc., can solve problems such as poor practical effect and single structure, and achieve the effect of improving practicability and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

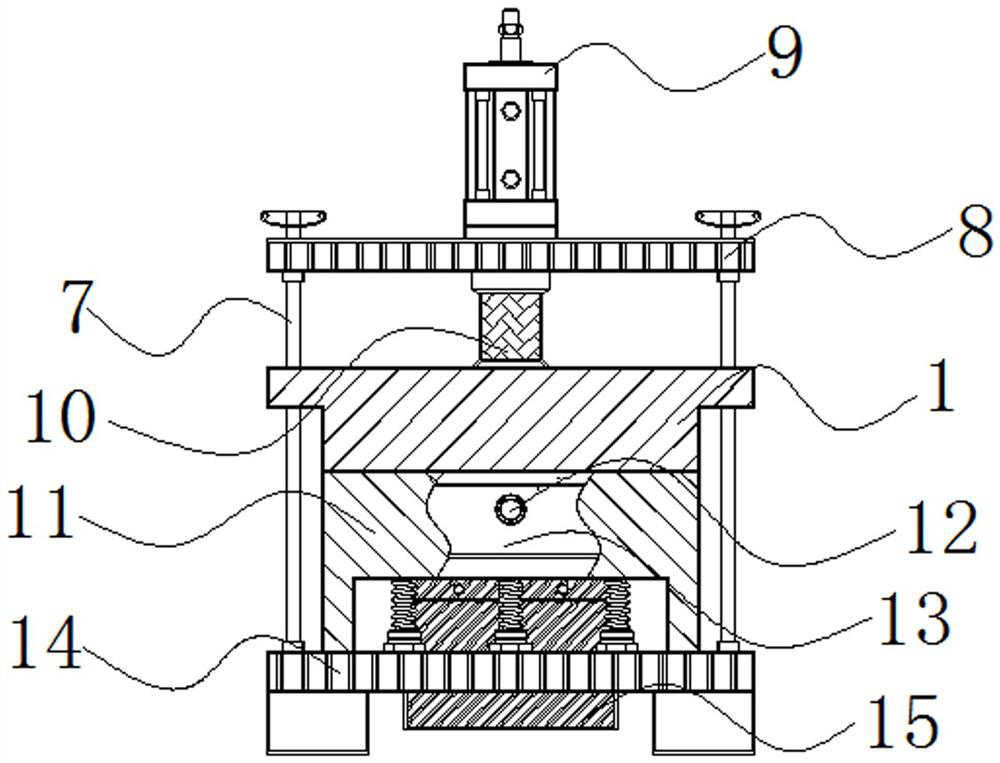

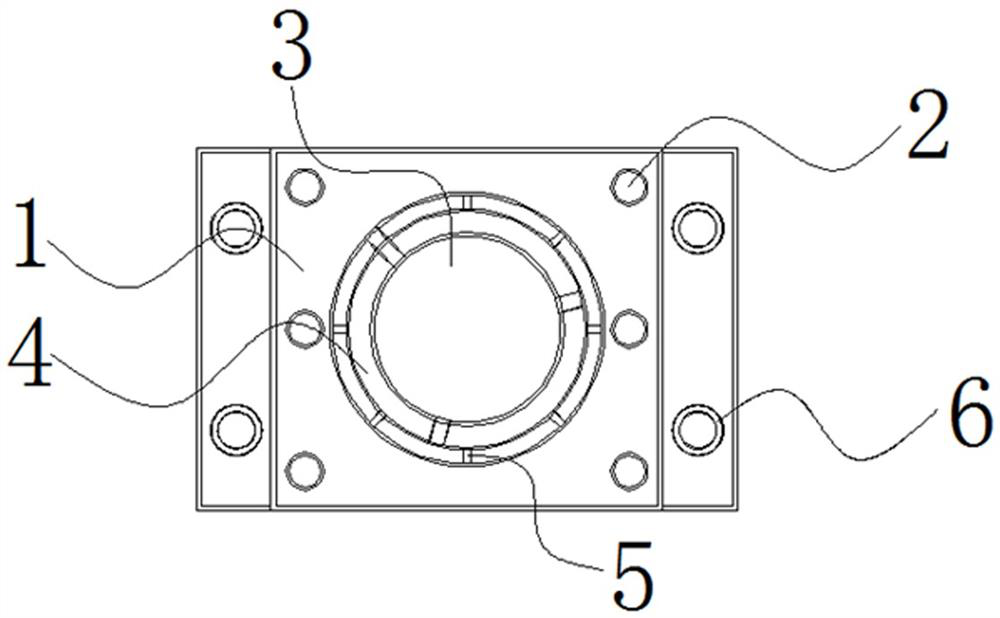

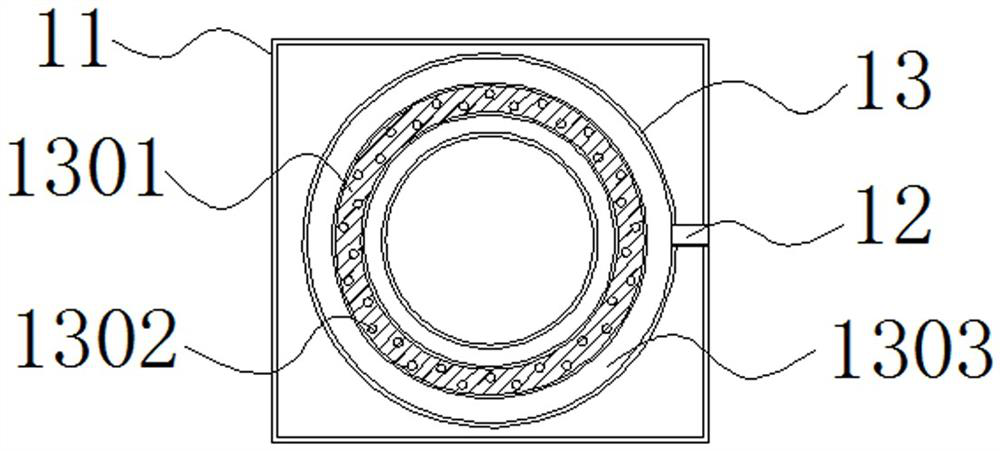

[0022] see Figure 1-5 , an optical glass forming mold device, comprising an upper mold 1, a sinking ring groove 4 and a positioning opening 5, the bottom of the upper mold 1 is fixed with a limited connecting column 2 around, and the middle part of the bottom of the upper mold 1 is provided with a template placement groove 3. The sinking ring groove 4 is opened on the outside of the formwork placement groove 3, and the positioning openings 5 are distributed on the outside of the sinking ring groove 4;

[0023] The specific operation is as follows. There are multiple sets of annular positioning openings 5 distributed equidistantly on the outside of the sinking ring groove 4. The positioning openings 5 are all in a rectangular concave shape, which fits the structure of the mold core. The opening 5 and the mold core are positioned and buckled, and then the forming template is positioned and installed, and a variety of different types of templates are respectively snapped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com