Low-toxicity gel system gel casting fused quartz ceramic method

A fused silica and injection molding technology, applied in the field of non-metallic materials, can solve the problems of low safety factor, indurability, complex production process, etc., and achieve the effects of high automation performance, uniform carcass structure, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

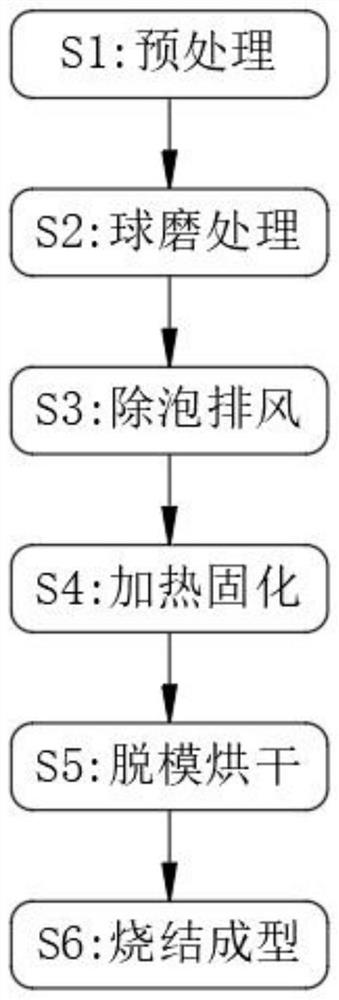

[0024] The present invention provides a technical solution: the embodiment of the present invention provides a technical solution: a method for casting a low-toxicity gel system into fused silica ceramics, the production steps include the following: S1, pretreatment: preparing fused silica ceramic powder and Mixed liquid, weigh 70 parts of fused silica ceramic powder, 30 parts of mixed liquid; S2, ball milling treatment: add dispersant and grinding balls in the preparation tank, then add the injected slurry, and perform ball milling treatment on the injected slurry; S3, defoaming and exhausting: add a certain amount of defoaming agent to the prepared slurry to defoam, and install an exhaust pipe on the top of the preparation tank; S4, heating and curing: place the slurry inside the heating plate of the stainless steel mold , the bottom of the stainless steel mold heating plate is installed with an electric heating tube, the bottom of the electric heating tube is electrically co...

example 2

[0026] The present invention provides a technical solution: the embodiment of the present invention provides a technical solution: a method for casting a low-toxicity gel system into fused silica ceramics, the production steps include the following: S1, pretreatment: preparing fused silica ceramic powder and Mixed solution, 80 parts of fused silica ceramic powder and 20 parts of mixed solution are weighed; S2, ball milling treatment: add dispersant and grinding balls to the preparation tank, then add the injected slurry, and perform ball milling treatment on the injected slurry; S3, defoaming and exhausting: add a certain amount of defoaming agent to the prepared slurry to defoam, and install an exhaust pipe on the top of the preparation tank; S4, heating and curing: place the slurry inside the heating plate of the stainless steel mold , the bottom of the stainless steel mold heating plate is installed with an electric heating tube, the bottom of the electric heating tube is el...

example 3

[0028] The embodiment of the present invention provides a technical solution: a method for casting a low-toxic gel system into fused silica ceramics, the production steps include the following: S1, pretreatment: prepare fused silica ceramic powder and mixed solution, and weigh fused silica ceramics 75 parts of powder, 25 parts of mixed solution; S2, ball milling treatment: add dispersant and grinding balls to the preparation tank, then add the injected slurry, and the injected slurry is subjected to ball milling treatment; S3, defoaming and exhausting: in The prepared slurry is defoamed after adding a certain amount of defoaming agent, and an exhaust pipe is installed on the top of the preparation tank; S4, heating and curing: the slurry is placed inside the stainless steel mold heating plate, and the bottom of the stainless steel mold heating plate is installed There are electric heating tubes distributed, and the bottom of the electric heating tubes is electrically connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com