Low-reflection glass cleaning agent for museum showcases and preparation method of low-reflection glass cleaning agent

A low-reflection, museum technology, applied in the preparation of detergent mixture compositions, chemical instruments and methods, detergent compositions, etc., can solve the problem of no anti-fog effect, etc., achieve good implementation effect, good cleaning effect, High-value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

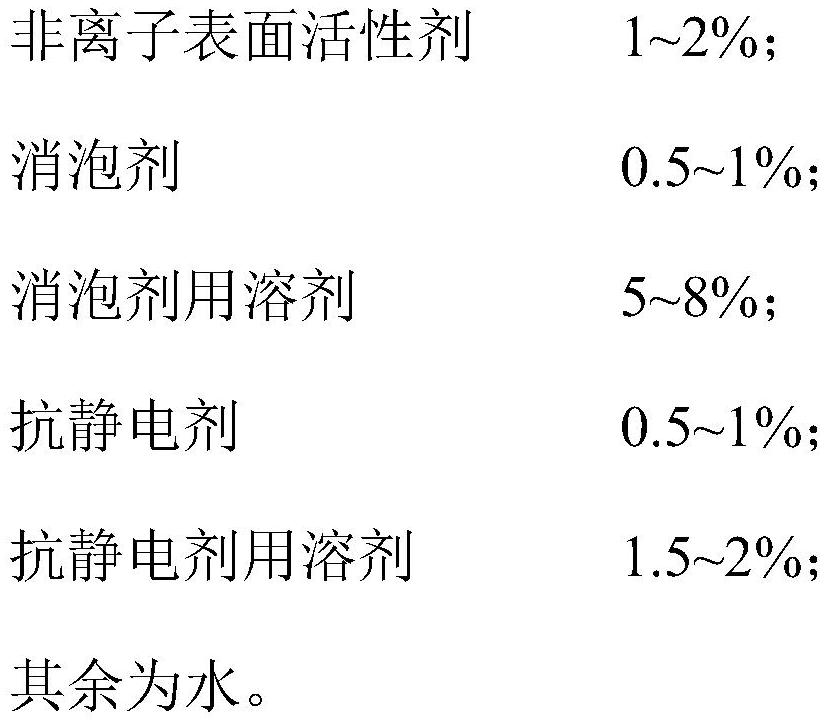

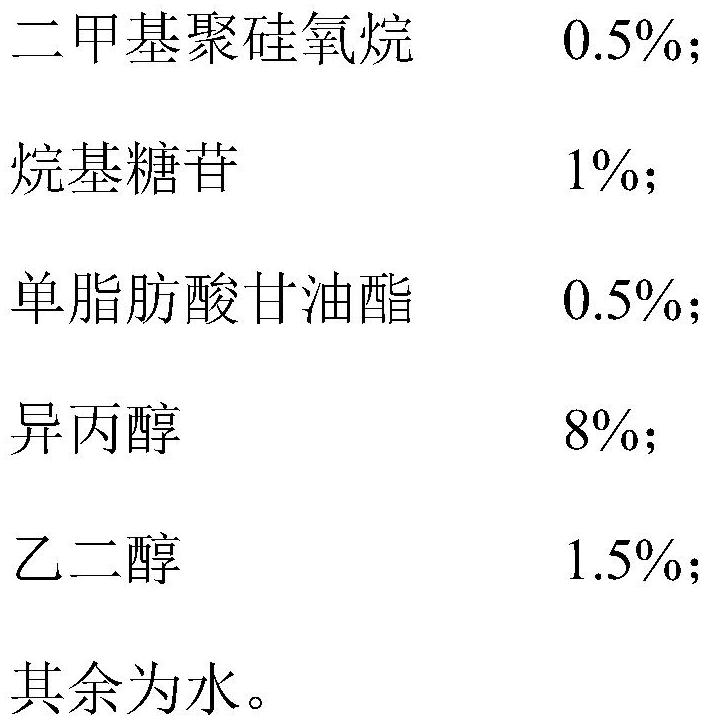

[0032] Step 1, dissolving 0.5kg of dimethyl polysiloxane in 5kg of alcohol to make a defoamer solution;

[0033] Step 2, 0.5kg monoglyceride is dissolved in 1.5kg ethylene glycol to make antistatic agent solution;

[0034] Step 3: Mix and stir 1 kg of alkyl glycoside, defoamer solution, antistatic agent solution, and 91.5 kg of water for 2-3 hours to prepare sample 1.

Embodiment 2

[0036] Step 1, dissolving 0.5kg of dimethyl polysiloxane in 5kg of isopropanol to make a defoamer solution;

[0037] Step 2, 0.5kg monoglyceride is dissolved in 1.5kg ethylene glycol to make antistatic agent solution;

[0038] Step 3: Mix and stir 1 kg of alkyl glycoside, defoamer solution, antistatic agent solution, and 91.5 kg of water for 2-3 hours to prepare sample 2.

Embodiment 3

[0040] Step 1, dissolving 0.5kg of dimethylpolysiloxane in 8kg of isopropanol to make a defoamer solution;

[0041] Step 2, 0.5kg monoglyceride is dissolved in 1.5kg ethylene glycol to make antistatic agent solution;

[0042] Step 3: Mix and stir 1 kg of alkyl glycoside, defoamer solution, antistatic agent solution, and 88.5 kg of water for 2-3 hours to prepare sample 3.

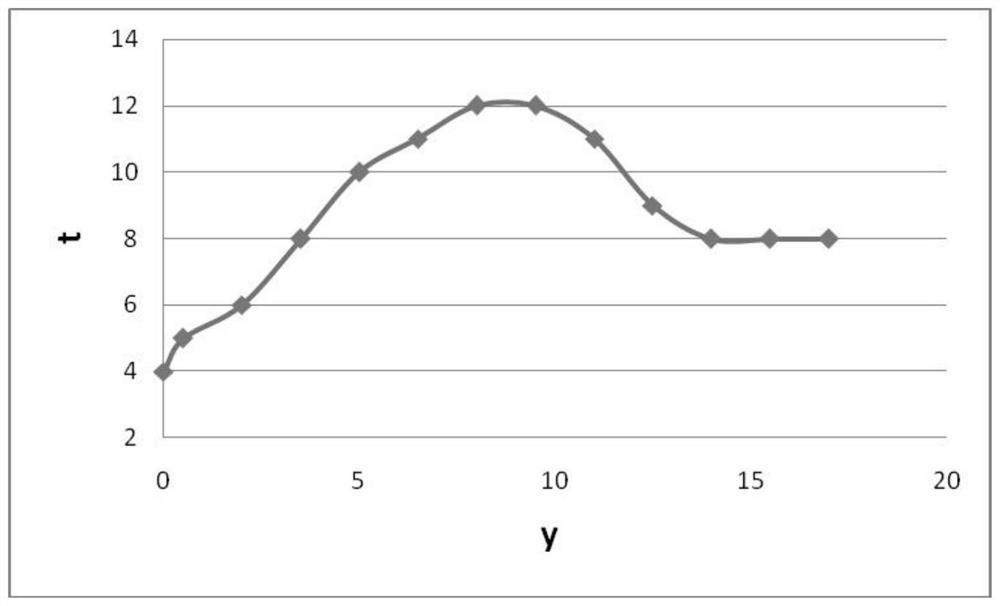

[0043] 1. Initial anti-fog effect test:

[0044] 1.1. Processing of glass samples to be tested

[0045] Use an ultrasonic cleaner to clean the surface of the low-reflection glass, and put it in an oven at 80°C for 60 minutes to dry it, so that the glass surface is clean and dry. Then use samples 1-3 to clean the glass samples to be tested respectively. After cleaning, the glass samples to be tested are subjected to an initial anti-fog test.

[0046] Fix the glass sample to be tested at a distance of 10cm from the steam outlet, turn on the switch of the electric steamer, and let the hot steam blow to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com