Ground torque swing range determination method and drill column torsional pendulum sliding well drilling method

A determination method and ground technology, applied in the determination of the ground torque swing range, in the field of drill string torsional sliding drilling based on the ground torque swing range, can solve the problem that the ground torque and the screw torque action area cannot intersect, the anti-support pressure effect is not obvious, The design of clockwise torque is too small to avoid serious problems of supporting pressure, improve sliding drilling efficiency and drilling speed, and improve the level of anti-drill string supporting pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

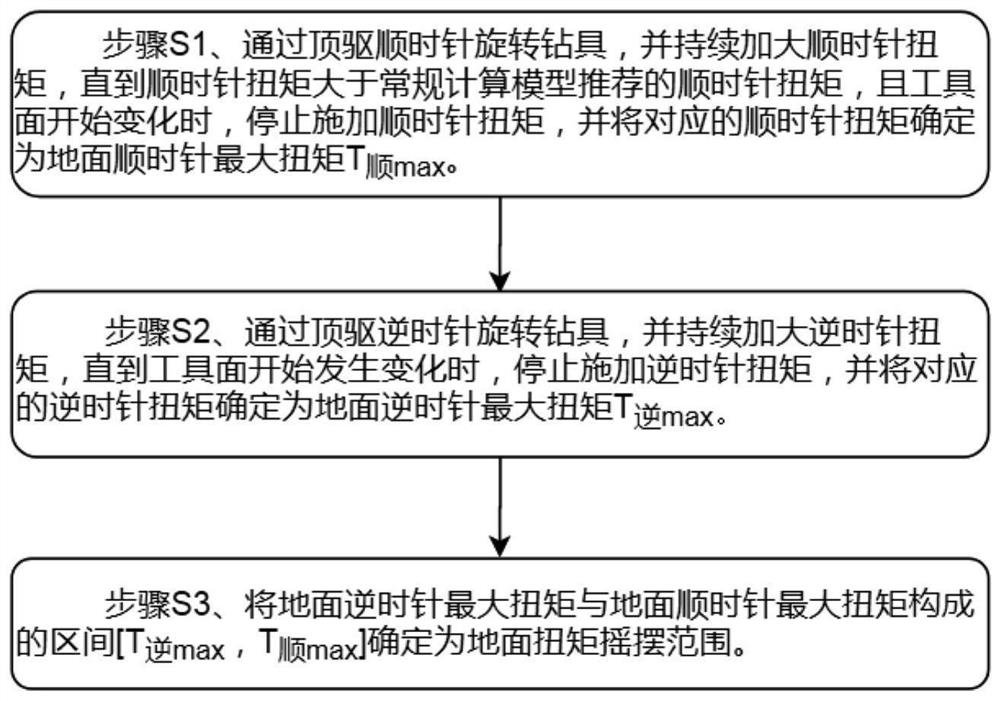

[0150] In order to realize precise control of the torsional force on the ground and give full play to the drag reduction effect of the torsional force on the ground, the present invention provides a simple and fast method for determining the swing range of the ground torque.

[0151] The method includes the following steps:

[0152] (1) When the top drive rotates the drilling tool clockwise, first apply the clockwise torque according to the clockwise torque value recommended by the conventional calculation model, and then continue to increase the clockwise torque by superimposing 150N.m each time until the clockwise torque is When it is applied to cause the lower drilling tool to start slowly (that is, the tool face starts to change), stop applying the clockwise torque, and determine the corresponding clockwise torque as the maximum clockwise torque on the surface T 顺max .

[0153] (2) When the top drive rotates the drilling tool counterclockwise, continue to increase the cou...

example 2

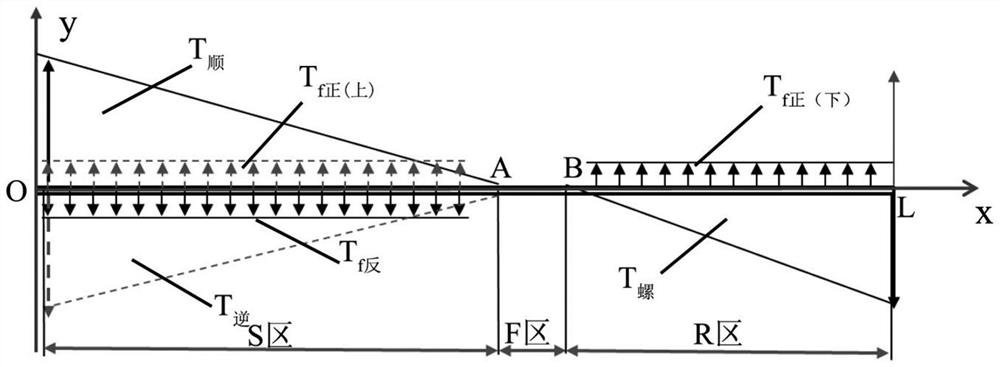

[0156] Such as Figure 6 As shown, a sliding drilling system includes a screw drilling tool 1 , a downhole drill string 2 and drilling equipment 3 . In order to improve the drilling efficiency and drilling speed of drill string torsional sliding, this example provides a method for determining the surface torque swing range.

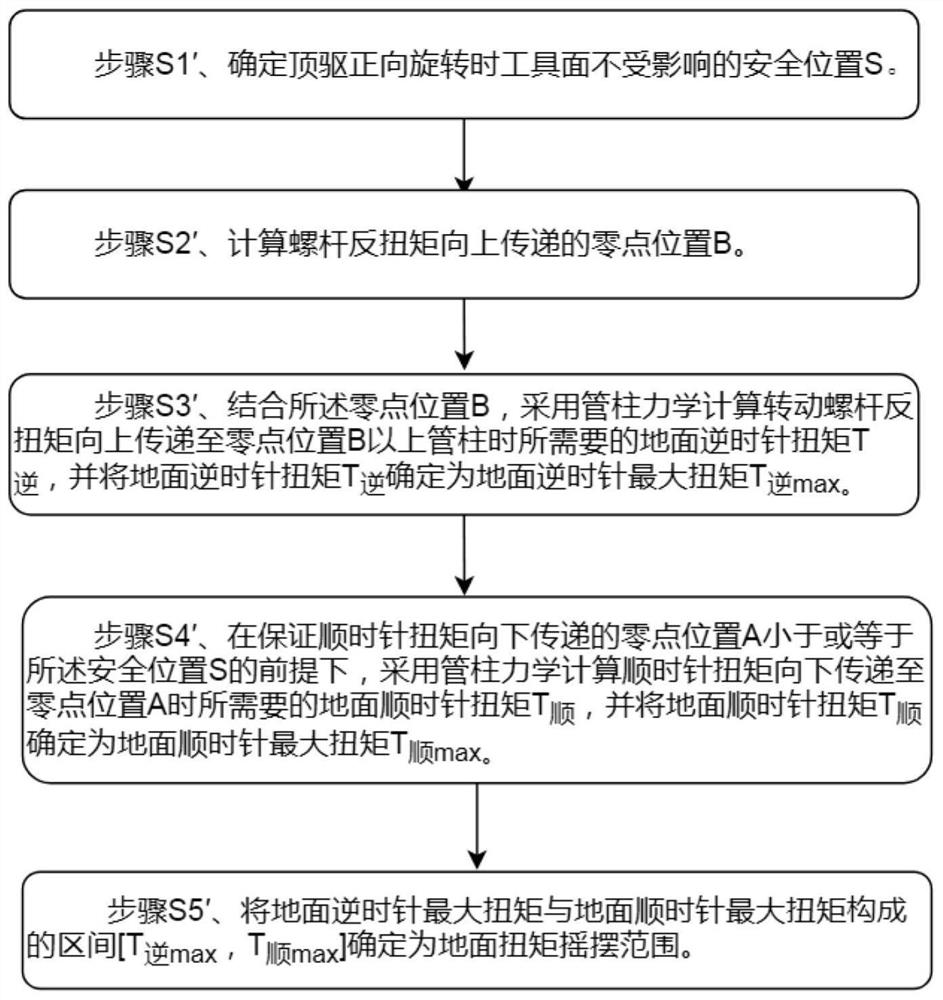

[0157] In this example, a method for determining the ground torque swing range may include the following steps:

[0158] (a) Analyze the drill tool assembly and determine the safe position S where the tool face is not affected.

[0159] (b) Calculate the zero position B of the upward transmission of the screw reaction torque.

[0160] (c) Calculate the counterclockwise ground torque and determine the maximum counterclockwise ground torque.

[0161] (d) Calculate the ground clockwise torque and determine the maximum ground clockwise torque.

[0162] (e) Determine the range of ground sway torque.

[0163] In step (a), the structure of the drill string ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com