Unidirectional transient suppression diode and preparation process thereof

A technology of transient suppression and preparation process, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of unstable breakdown voltage, increased cost, TVS reliability easily affected by charges, etc., to achieve Effect of improving negative surge capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

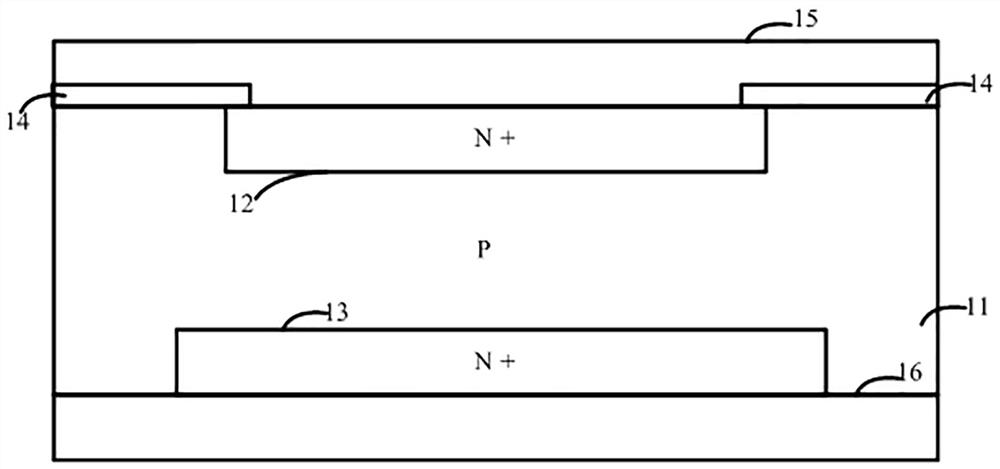

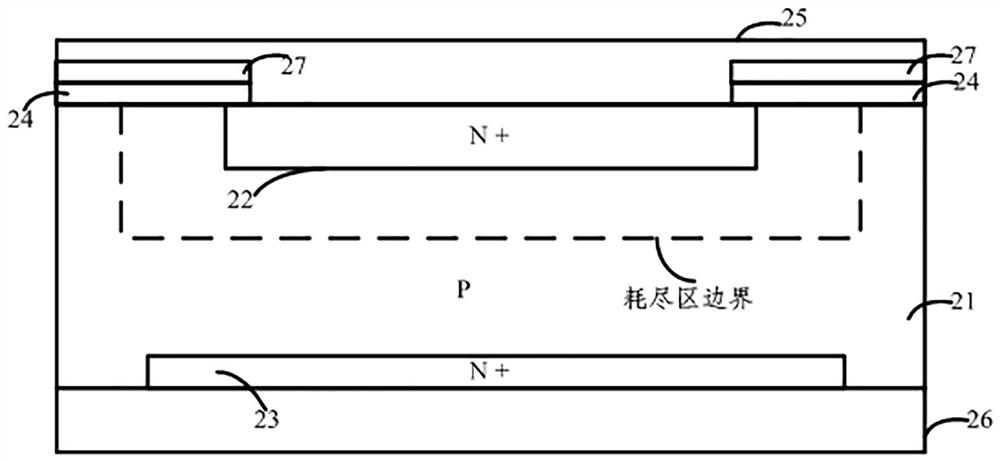

[0040] Such as figure 2 As shown, the embodiment of the present application provides a unidirectional TVS diode, including a substrate 21 of a first conductivity type, a first injection region 22 and a second injection region 23 of a second conductivity type;

[0041] The first implantation region 22 is arranged on the front side of the substrate 21, and the second implantation region 23 is arranged on the backside of the substrate 21, wherein the junction depth of the pn junction formed between the second implantation region 23 and the substrate 21 is smaller than that between the first implantation region 22 and the substrate 21. The junction depth of the pn junction formed between the substrates 21 is provided with a barrier layer 24 and an insulating layer 27 sequentially from bottom to top on the front surface of the substrate 21; the first injection region 22 draws out the first electrode through the first metal 25, The insulating layer 27 is arranged between the barrie...

Embodiment 2

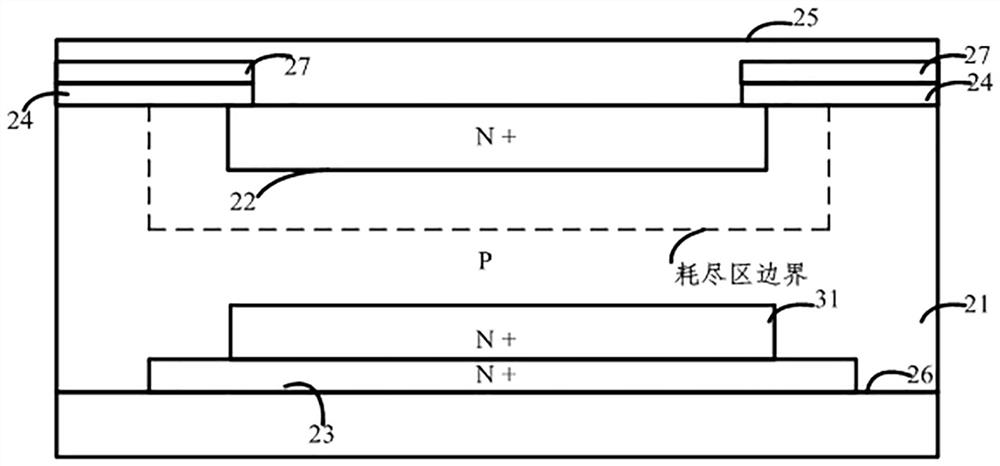

[0045] On the basis of Example 1, such as image 3 As shown, the diode provided by the embodiment of the present application also includes a third implantation region 31 of the second conductivity type, the second implantation region 23 is larger than the width of the third implantation region 31, and the second implantation region 23 on the back side is set to be third than the front side of the substrate. The reason why the first injection region 22 is wide is that the second injection region 23 on the back side is an electron emission region, and the quantity of electron emission is related to the area. The larger the area, the more electrons are emitted, and the stronger its flow capacity is. In the embodiment of the present application, the first The junction depth of the pn junction formed between the third implant region 31 and the substrate 21 is greater than the junction depth of the pn junction formed between the first implant region 22 and the substrate 21, and the s...

Embodiment 3

[0048] On the basis of Example 3, as Figure 4 As shown, the unidirectional TVS diode provided by the embodiment of the present application further includes a fourth injection region 42 of the first conductivity type and / or a fifth injection region 41 of the second conductivity type; the fifth injection region 41 covers the first An injection region 22, the fifth injection region 41 is separated from the first injection region 22 by a preset distance, and the boundary of the depletion region on the surface can be extended gently by the distance between the fifth injection region 41 and the first injection region 22. The fourth injection region 42 covers the second injection region 23, The fourth implantation region 42 is in contact with the second implantation region 23, and the fourth implantation region 42 is in contact with the second implantation region 23 on the back side of the substrate to form a pn between the fourth implantation region 42 and the second implantation re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com