Flexible photovoltaic module integrated structure and system and installation method of system

A technology of photovoltaic modules and installation methods, which is applied to the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation, etc., which can solve the problems of life mismatch of power generation, secondary maintenance cost, component falling off and damage, and difficult life span, etc., to reduce the cost of materials Cost and installation cost, safe and reliable installation structure, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

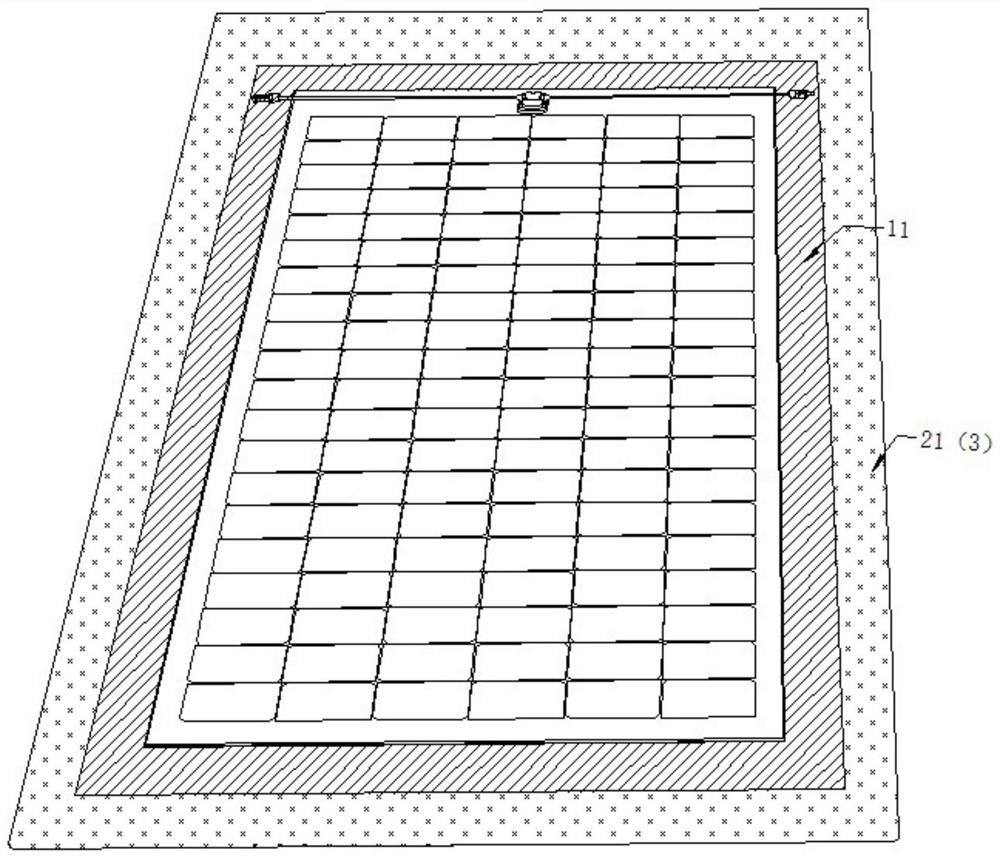

[0037] Such as Figure 1-4 As shown, the flexible photovoltaic module integrated system includes a roof structure 2 and a flexible photovoltaic module integrated structure 1 fixed on the roof structure 2 by hot air welding. The flexible photovoltaic module integrated structure 1 is the above-mentioned flexible photovoltaic module integration Chemical structure 1.

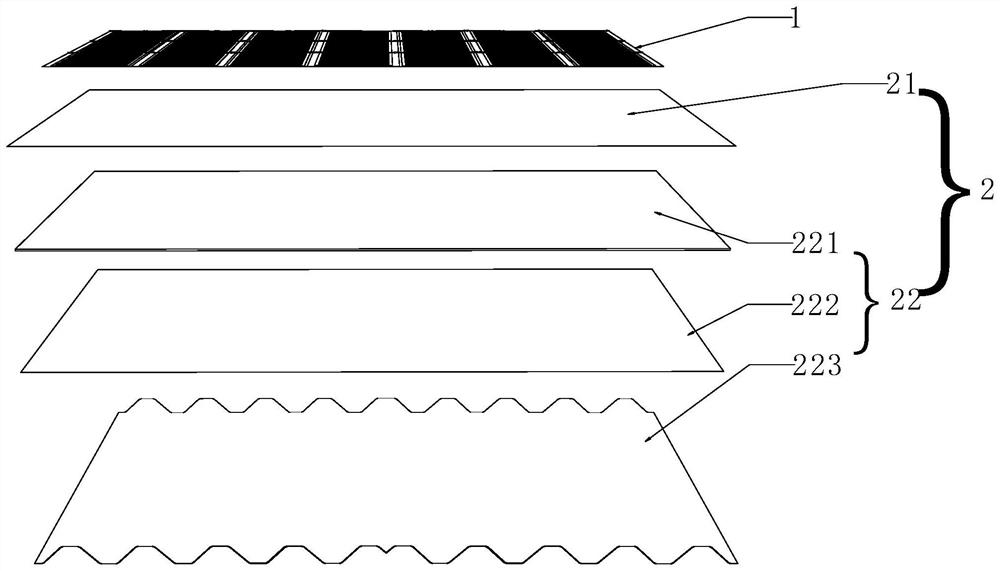

[0038] The roof structure 2 includes a main waterproof roll material 21 and a roof base material 22 below the main waterproof roll material 21 . The roof base material 22 includes a thermal insulation layer 221 , a waterproof and air-permeable layer 222 under the thermal insulation layer 221 , and a steel plate load-bearing layer 223 under the waterproof and air-permeable layer 222 .

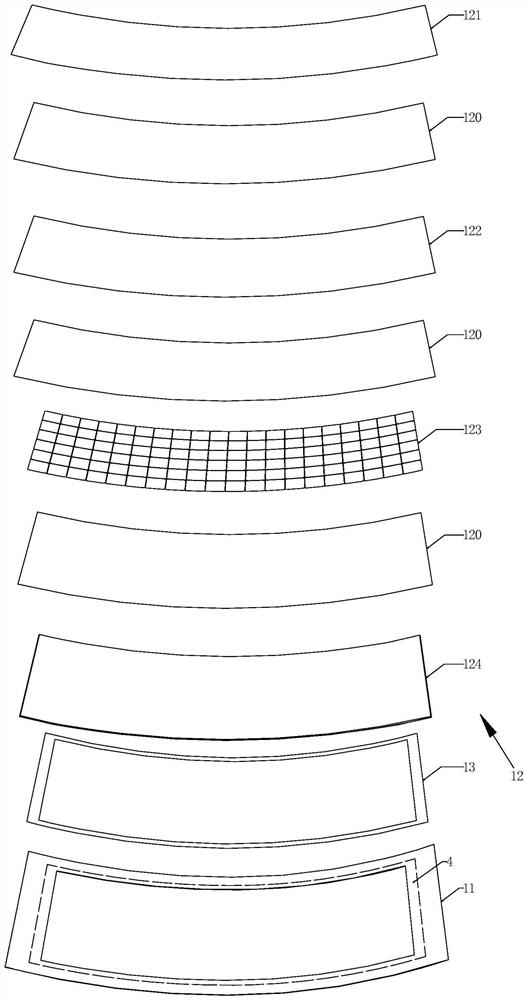

[0039] Flexible photovoltaic module integrated structure 1, which includes a secondary waterproof roll material 11, a flexible photovoltaic component 12 integrated on the front side of the secondary waterproof roll material 11, and a...

Embodiment 2

[0055] Such as figure 1 , 2 , 7, the flexible photovoltaic module integrated system includes a roof structure 2, and a flexible photovoltaic module integrated structure 1 fixed on the roof structure 2 by hot air welding, and the flexible photovoltaic module integrated structure 1 is the above-mentioned flexible photovoltaic module Component integration structure 1.

[0056] The roof structure 2 includes a main waterproof roll material 21 and a roof base material 22 below the main waterproof roll material 21 . The roof base material 22 includes a thermal insulation layer 221 , a waterproof and air-permeable layer 222 under the thermal insulation layer 221 , and a steel plate load-bearing layer 223 under the waterproof and air-permeable layer 222 .

[0057] Flexible photovoltaic module integrated structure 1, which includes a secondary waterproof roll material 11, a flexible photovoltaic component 12 integrated on the front side of the secondary waterproof roll material 11, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com