LED epitaxial structure and preparation method thereof

An epitaxial structure and structure layer technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the injection efficiency and luminous efficiency of light-emitting diodes, high junction temperature of LED chips, lattice mismatch, etc., to reduce internal reflection. Loss, performance improvement, effect of reducing operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

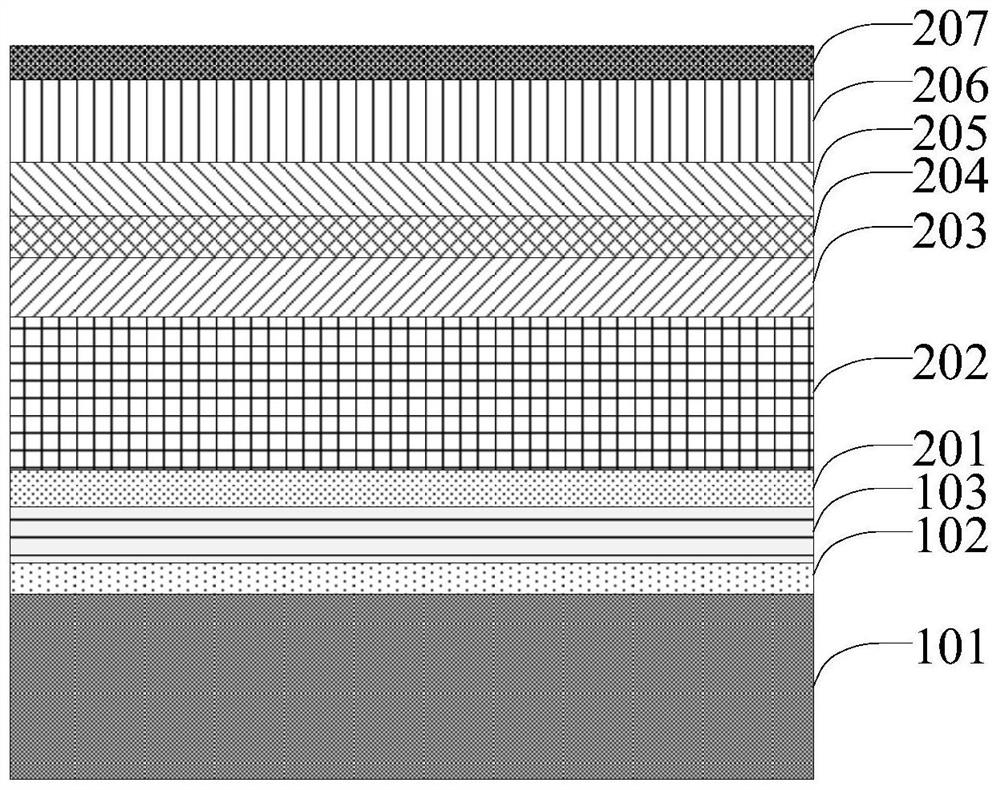

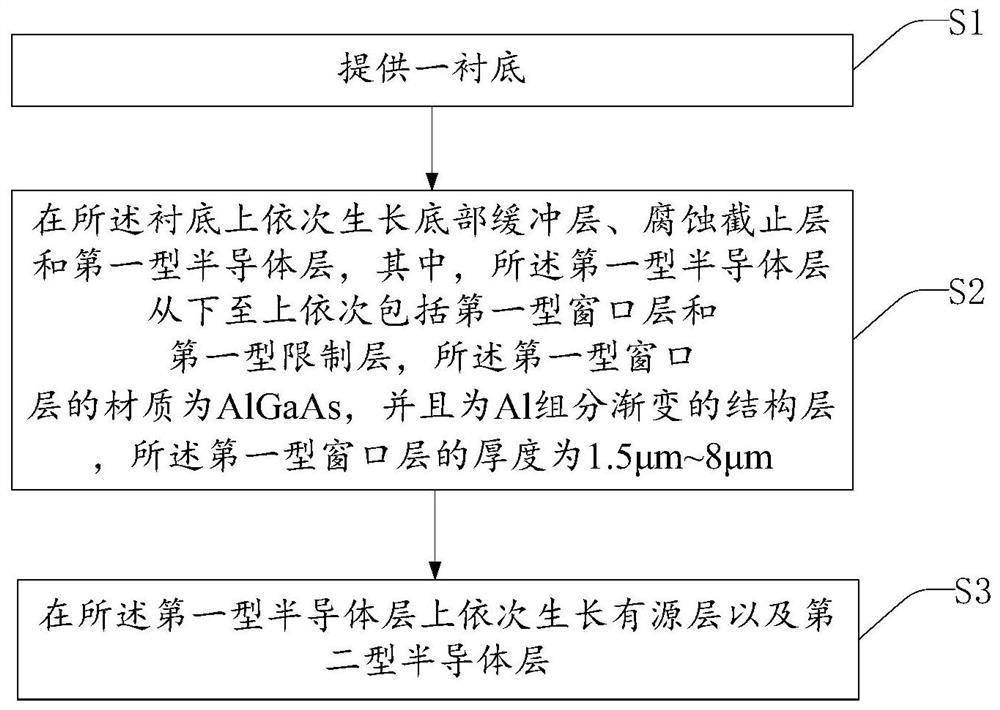

[0048] figure 1 It is a structural schematic diagram of the LED epitaxial structure of this embodiment. refer to figure 1 , the LED epitaxial structure includes from bottom to top: a bottom buffer layer 102 on the substrate 101, an etch stop layer 103, a first-type semiconductor layer, an active layer 204, and a second-type semiconductor layer, wherein the first The semiconductor layer includes a first-type window layer 202 and a first-type confinement layer 203 from bottom to top, and the first-type window layer 202 is a structural layer with a graded Al composition.

[0049] The first type semiconductor layer further includes a first type ohmic contact layer 201 , and the first type ohmic contact layer 201 is located between the etching stop layer 103 and the first type window layer 202 .

[0050] The second-type semiconductor layer includes, from bottom to top, a second-type confinement layer 205 , a second-type window layer 206 and a second-type ohmic contact layer 207 ....

Embodiment 2

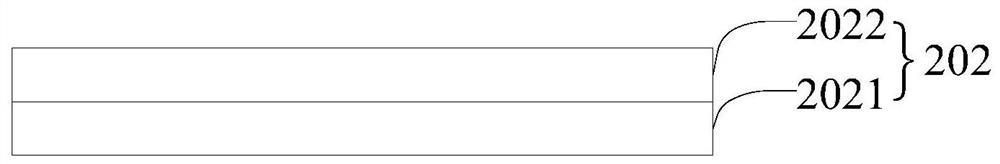

[0084] figure 2 It is a structural schematic diagram of the first type window layer of this embodiment. The difference between this embodiment and the first embodiment is only that the structure of the first-type window layer 202 is different, and the parts with the same structure will not be repeated here.

[0085] Specifically, the first-type window layer 202 in the LED epitaxial structure includes a two-layer structure composed of the first structure layer 2021 and the second structure layer 2022 or a structure composed of the first structure layer 2021 and the second structure layer 2022 stacked alternately. In the multi-period structure, the period number k ranges from 2 to 30, preferably 20-30. Such as figure 2 As shown, the first-type window layer 202 includes a two-layer structure composed of a first structural layer 2021 and a second structural layer 2022 . The material of the first structural layer 2021 is Al a Ga 1-a As, the material of the second structural ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com