Grinding device for powder photocatalytic material

A technology of photocatalytic materials and powder grinding, which is applied in the fields of application, chemical instruments and methods, cleaning methods and appliances, etc. It can solve the problems of uneven grinding parts, the failure of ground materials, and the reduction of the powder output rate of the device. Increase the service life, prevent clogging, and prevent the effect of air flow disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

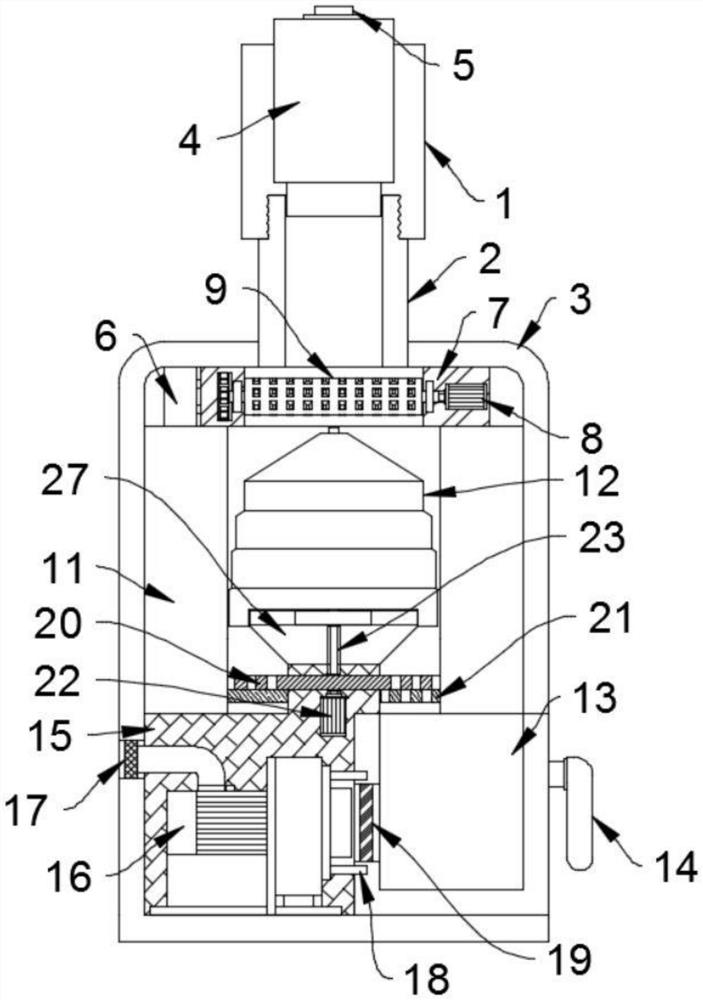

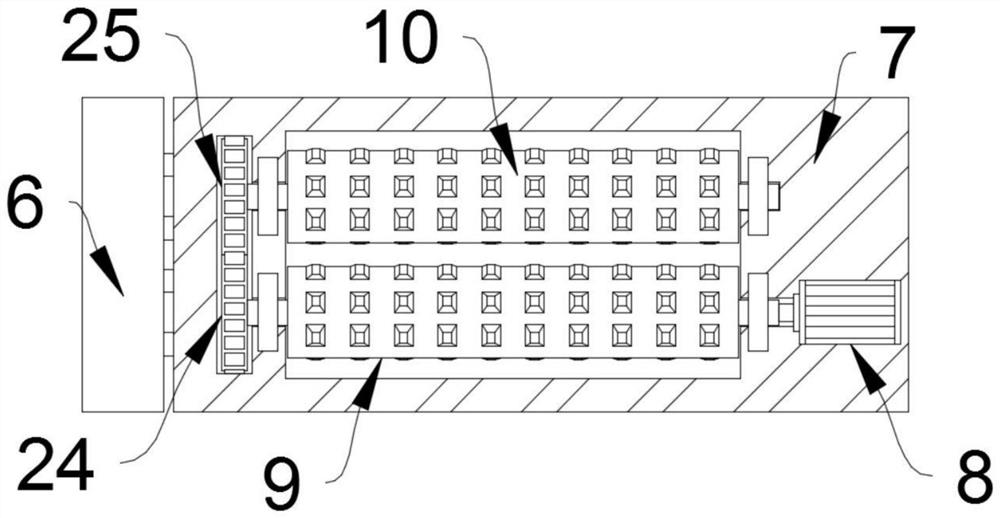

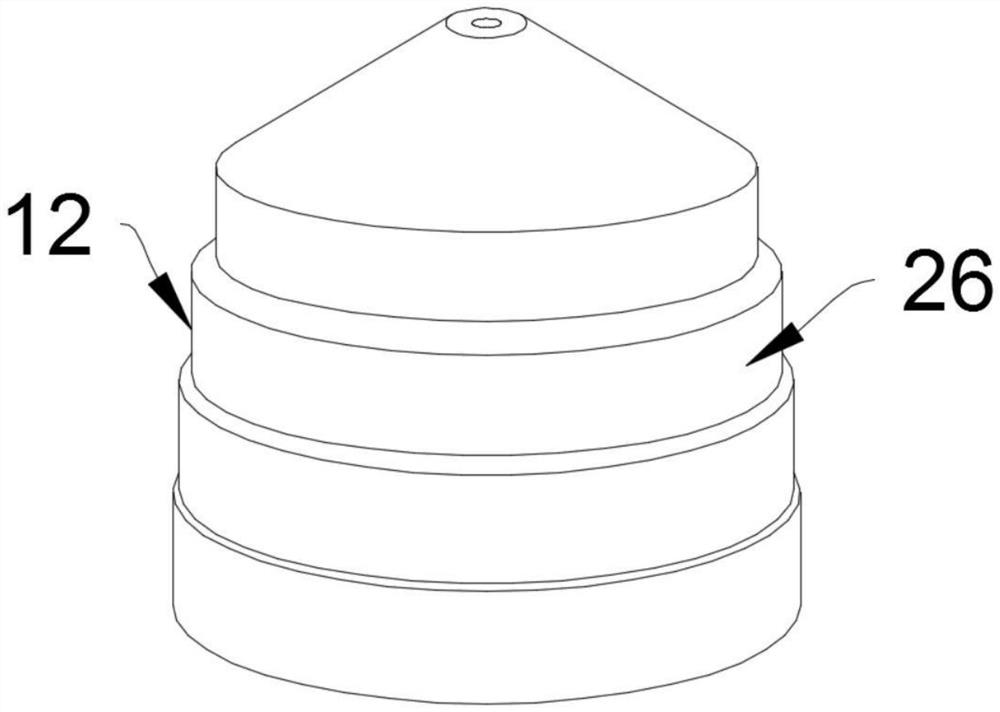

[0025] See Figure 1-5 In one embodiment of the present invention, an example of a grinding apparatus for a powder photocatalytic material comprising a main body housing 3, an internal portion of the main body housing 3 having a primary grinding block 7, and a primary grinding block 7 The main body housing 3 is slidably connected by the jitter cylinder 6, and after the propulsion cylinder 4 completely pushes the photocatalytic material through the first coarse mill 9 and the second coarse grinding roller 10, the jitter cylinder 6 starts to drive the primary grinding block 7 and the interior The component is turned back and forth, thereby separating the photocatalytic material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com