Welding positioning system and laser welding equipment for casting outer wrapping part

A welding positioning and laser welding technology, applied in the field of machinery, can solve the problems of unstable welding quality, difficult clamping and positioning, and low manual welding efficiency, achieve a high degree of automation and intelligence, improve the stability of welding quality, and solve manual The effect of low welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Preferred embodiments of the present invention are provided below to help further understanding of the present invention. Those skilled in the art should understand that the descriptions of the embodiments of the present invention are only exemplary, and are not intended to limit the solution of the present invention.

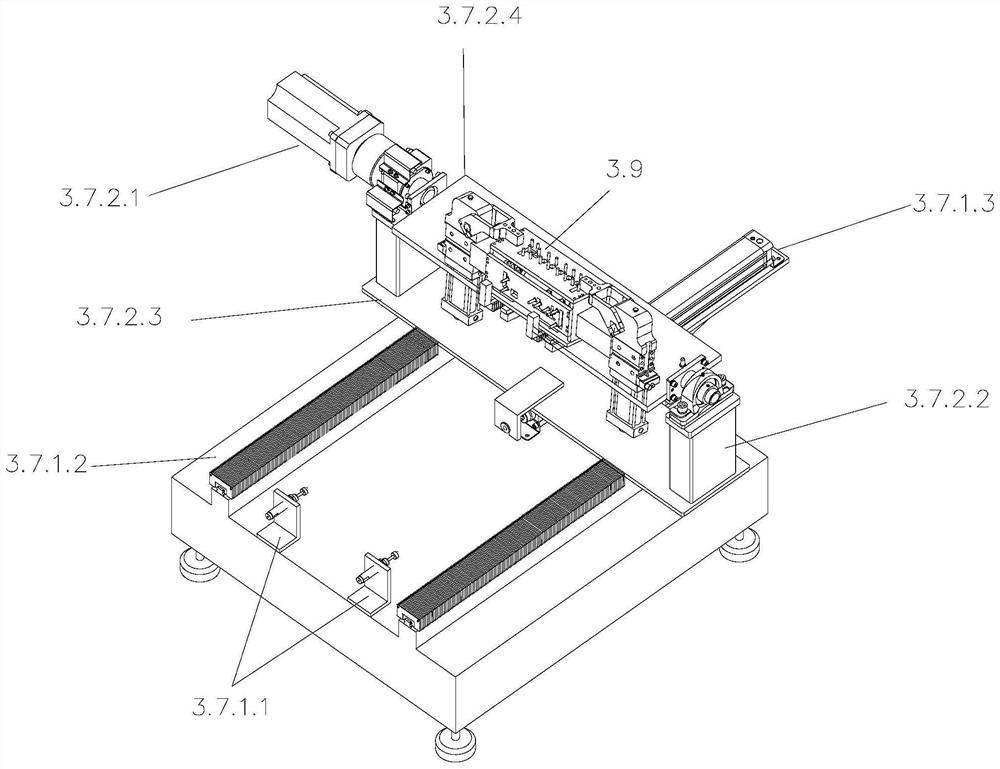

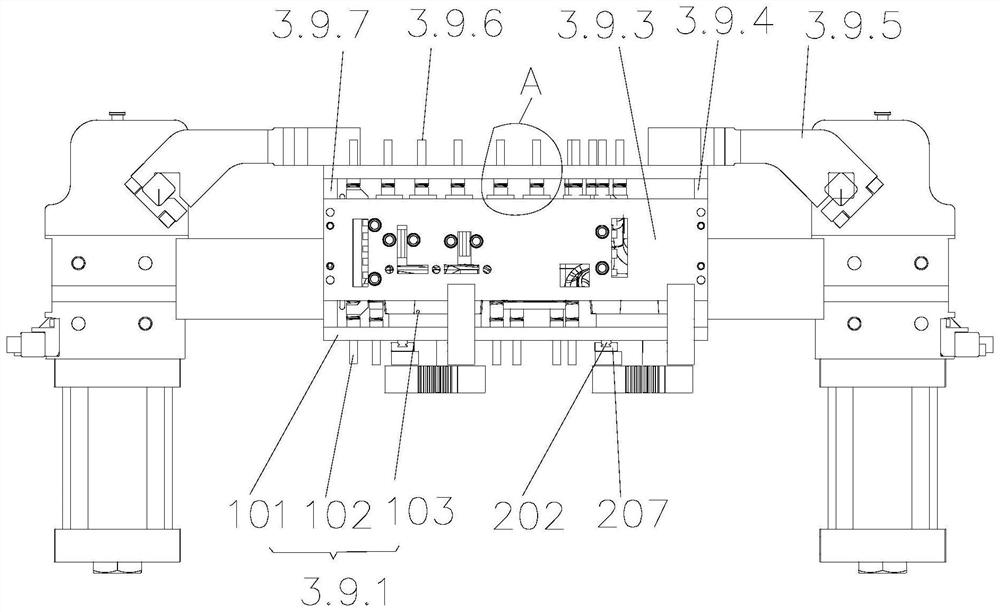

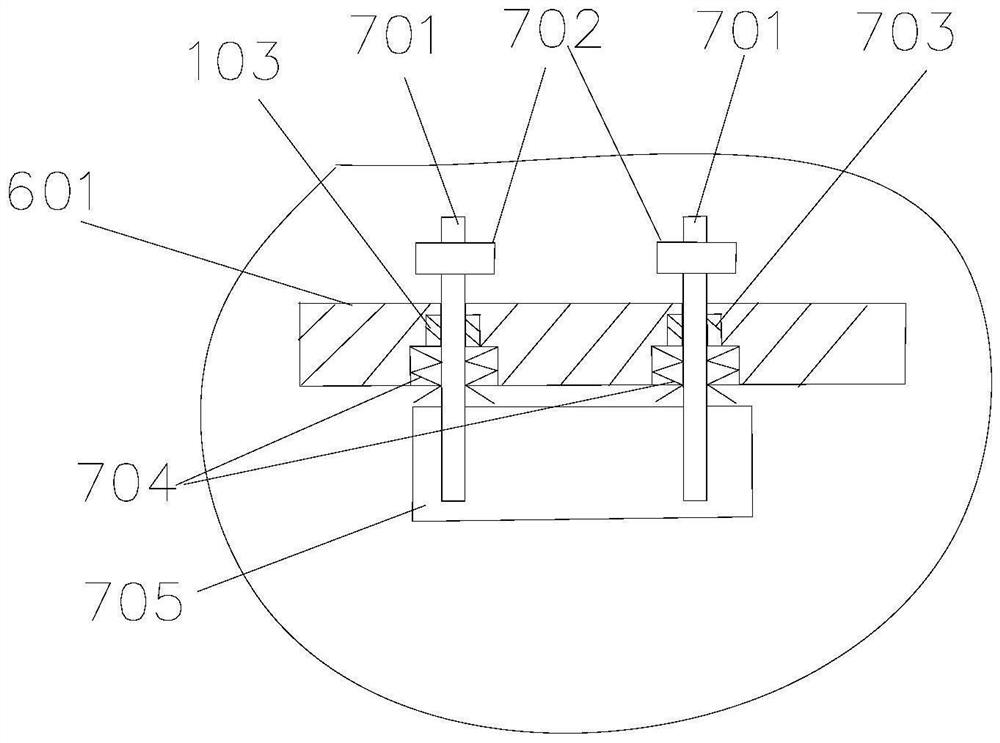

[0051] See attached figure 1 to attach Figure 7 The schematic diagram, the welding positioning system of the outer cladding of castings in an embodiment of the present invention includes a position transformation unit 3.7 and a clamping unit 3.9, the position transformation unit 3.7 includes a rotary displacement mechanism, and the rotary displacement machine includes a support assembly 3.7 .2.2, drive assembly 3.7.2.1, connection base plate 3.7.2.3 and installation plate 3.7.2.4, support assembly 3.7.2.2 is set on connection base plate 3.7.2.3, both ends of installation plate 3.7.2.4 are set on support assembly 3.7 .2.2, the clamping unit 3.9 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com