Formula of nano-antibacterial pipe and single-screw extruder for processing nano-antibacterial pipe

A single-screw extruder and extruder technology, applied in the field of nanometer antibacterial pipe extruder, can solve the problems of unfavorable feeding, small diameter of feeding hopper, long time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific embodiments.

[0031] like Figure 1 - Figure 8 As shown, the formulation of a nano-antibacterial tube according to the present invention comprises a raw material according to the following weight ratio: silica load nano silver antibacterial agent 0.3 ~ 2%, PE raw materials 94 ~ 95.7%, toner 2%, antioxidant 2% of the agent; wherein the silica load nano silver antibacterial agent is prepared by mixing nitrate, orthosateic acid ethyl ester, anhydrous ethanol and ammonia and ammonia and is reduced by a reducing agent.

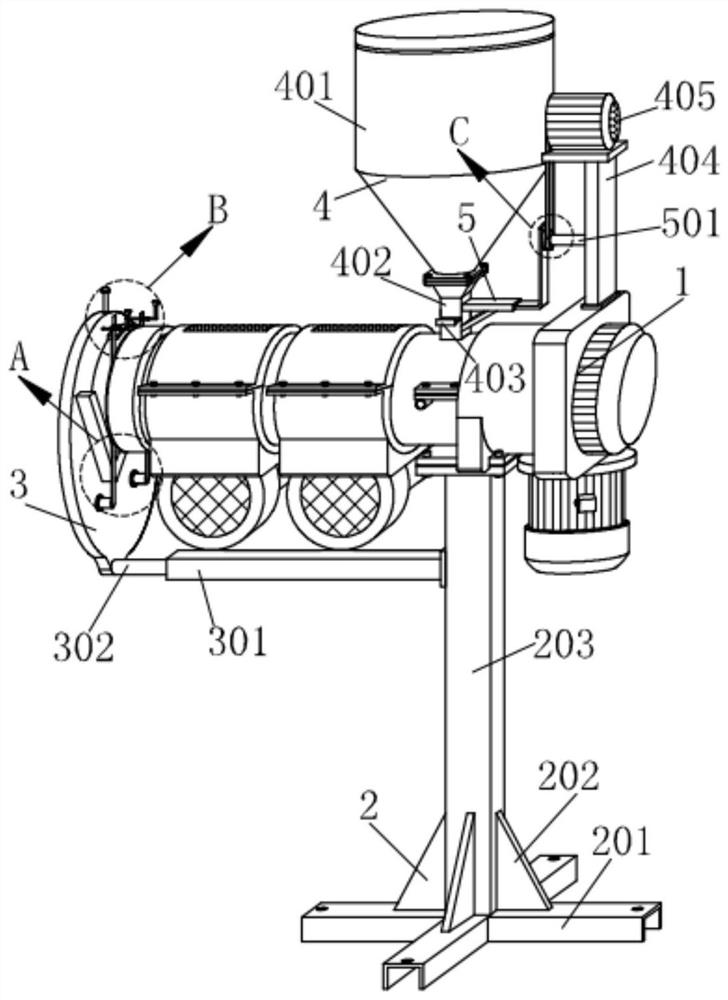

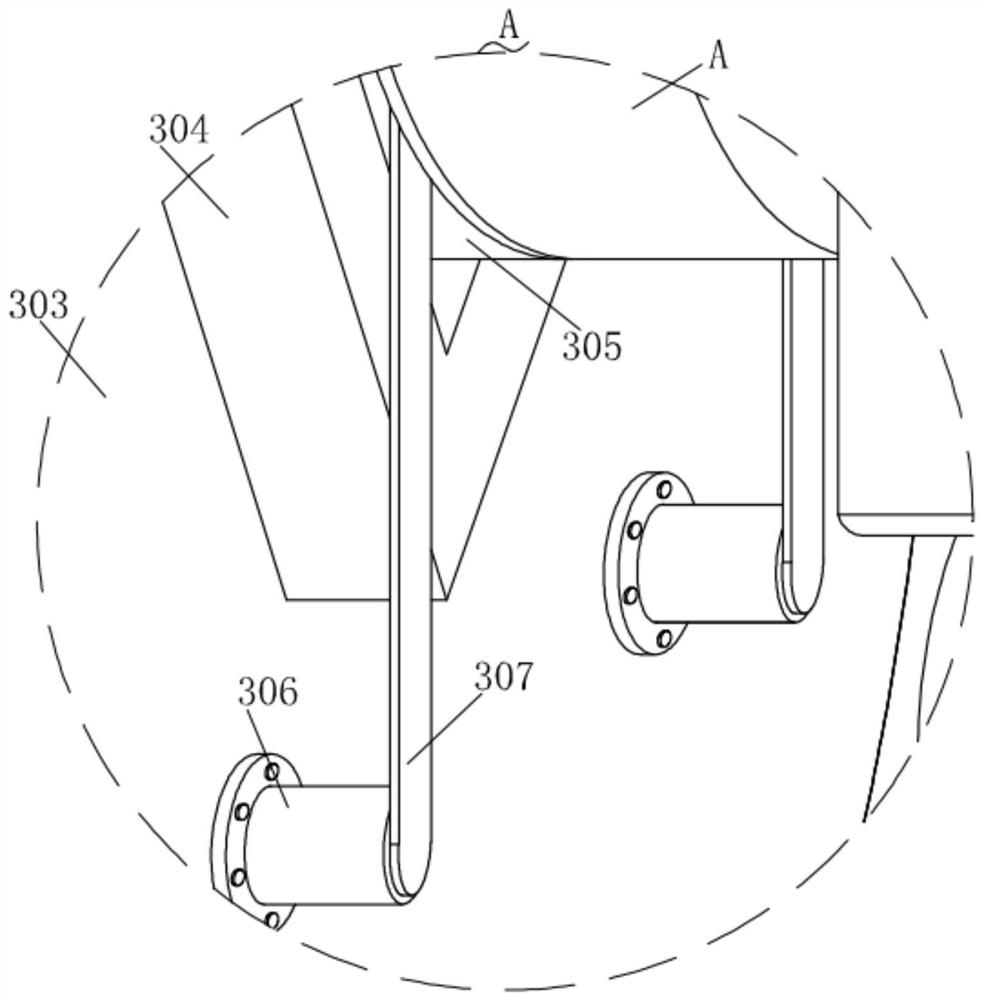

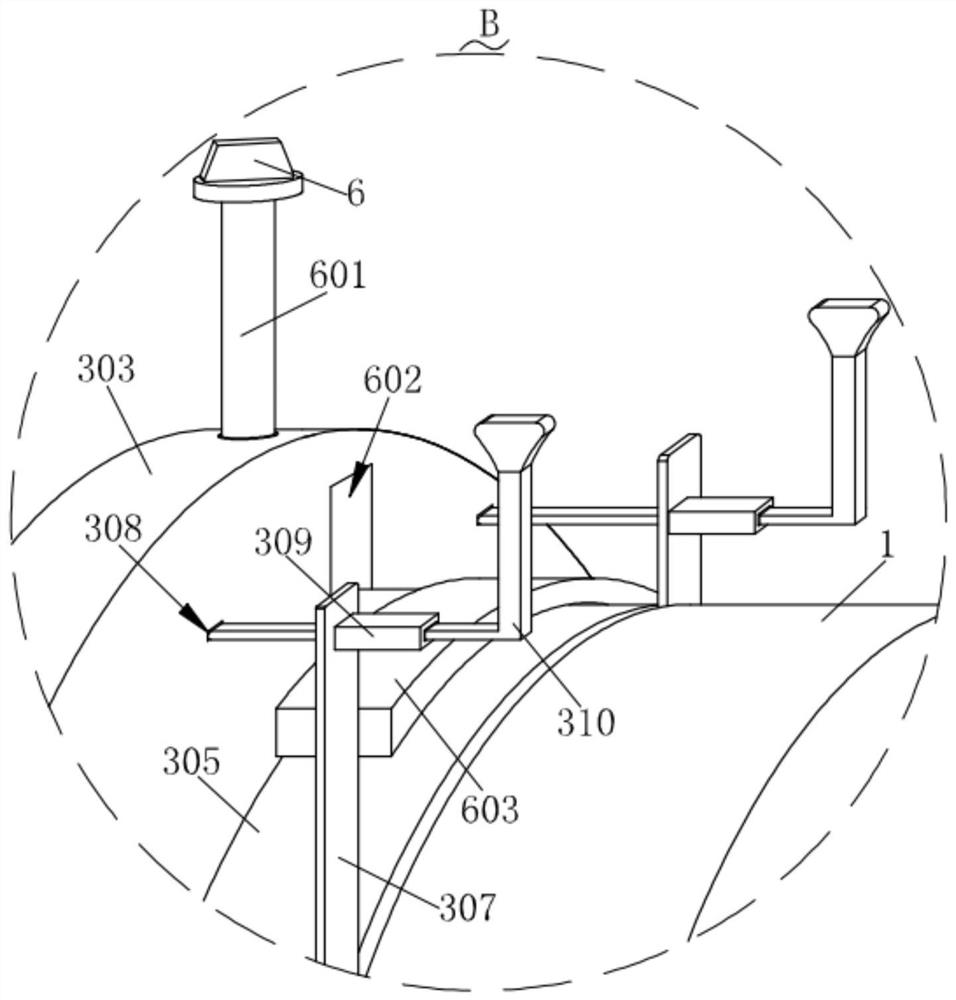

[0032]A single screw extruder processed by a nano antibacterial tube comprising an extruder body 1, and a support mechanism 2 is attached to the extruder body 1, and the extruder body 1 is attached to the raw material. The upper body 4 is mounted o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com