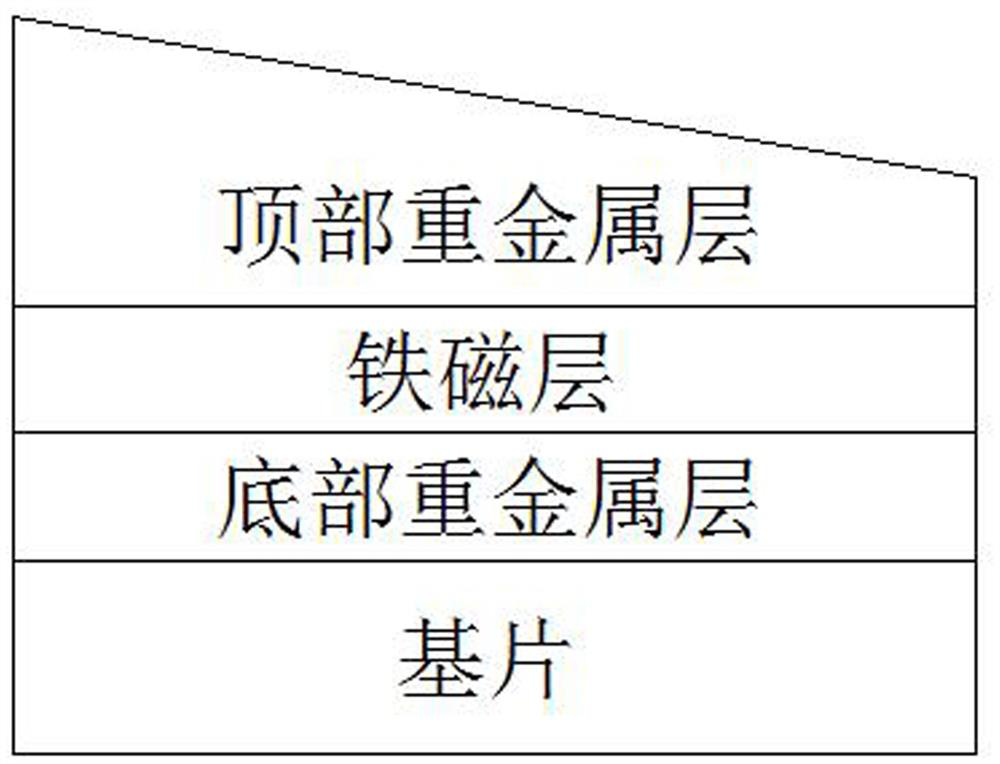

A heavy metal/ferromagnetic/heavy metal heterojunction realizing field-free switching and its preparation method

A heavy metal, heterojunction technology, applied in metal material coating process, manufacturing/processing of electromagnetic devices, components of electromagnetic equipment, etc., to achieve the effects of low cost, convenient preparation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

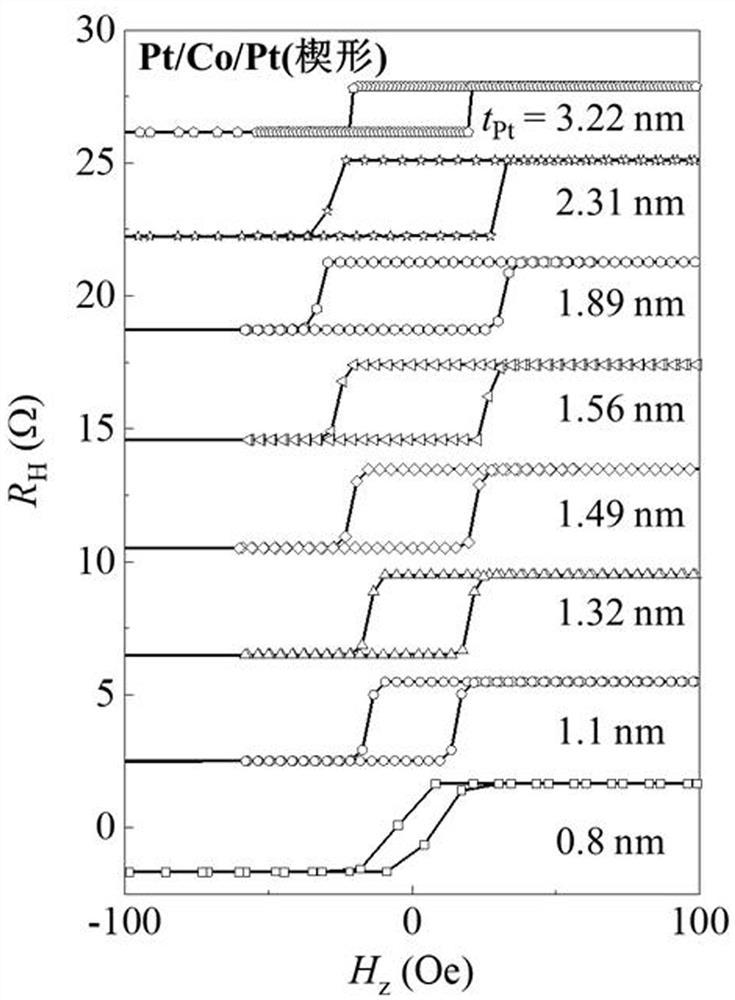

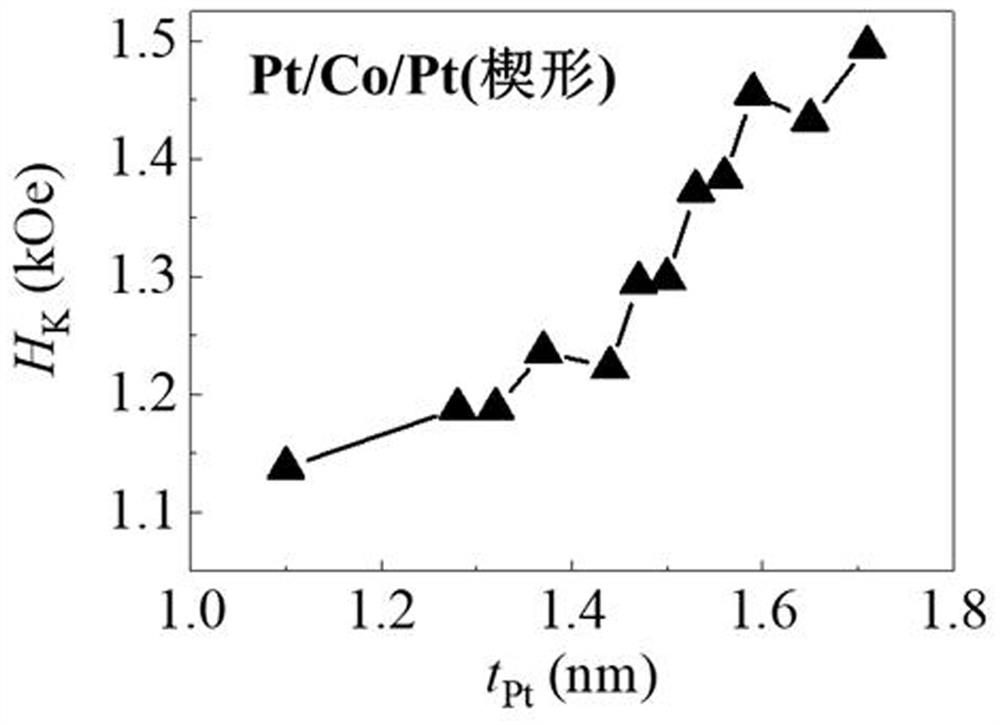

[0028] (2) Si / SiO with a length of 95 mm and a width of 10 mm 2 Put the long substrate into the circular tray, the substrate is symmetrical about the center of the tray, and then put the tray into the sample transfer chamber;

[0029] (3) Close the magnetron sputtering chamber and the sample transfer chamber, and the baffle valve between the two chambers is also closed, and the sputtering chamber and the sample transfer chamber are respectively evacuated;

[0030] (4) When the background vacuum of the magnetron sputtering chamber is better than 1.0×10 -5 Pa, enter the argon gas with a purity of 99.99% into the magnetron sputtering chamber, adjust the flow rate of the argon gas so that the pressure of the argon gas is 0.45 Pa, start the sputtering switch of the Pt target position and the Co target position, and the sputtering switch of the Pt target position The sputtering power was 40 W, and the pre-sputtering was 2 min. The sputtering power of the Co target was 50 W, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com