Design method for air supply flow of low-temperature liquid rocket blow-off branch pipe

A cryogenic liquid and design method technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as lack of versatility, complicated design process, etc., to reduce complexity, reduce launch cost, and design result accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

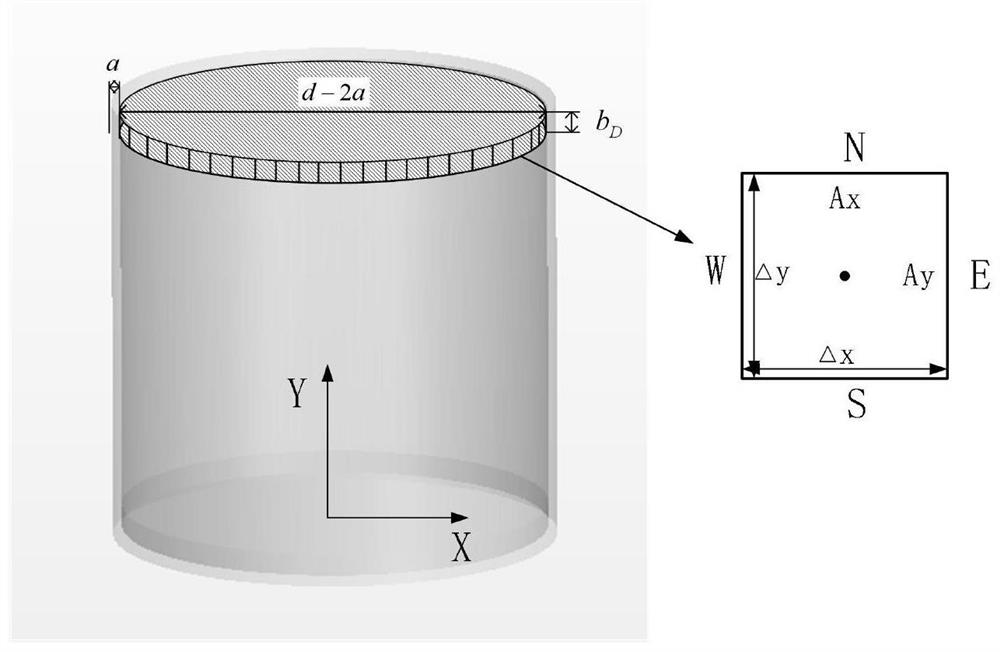

[0043] S1, according to the overall input, determine the propellant temperature T liq Geometric parameters of the manner, and the physical parameters of the compartments, and determine the target average temperature T in the hatch. air ;

[0044] S2, according to the overall input, determine the ambient temperature T of the launch day env And ground average wind speed V;

[0045] S3, according to the input parameters in step S2, calculate the convection heat exchange coefficient h outside the bulkhead. out ;

[0046] S4, the convection heat transfer coefficient h in the bulkhead in The value range is 1-10W / m 2 , The value is made by larger loss of heat in the cabin, and the amount of flow is smaller.

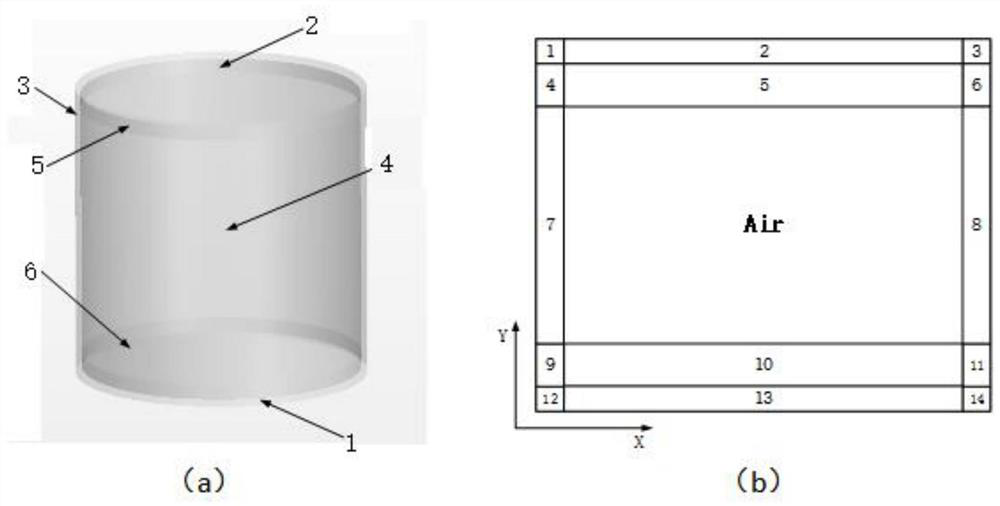

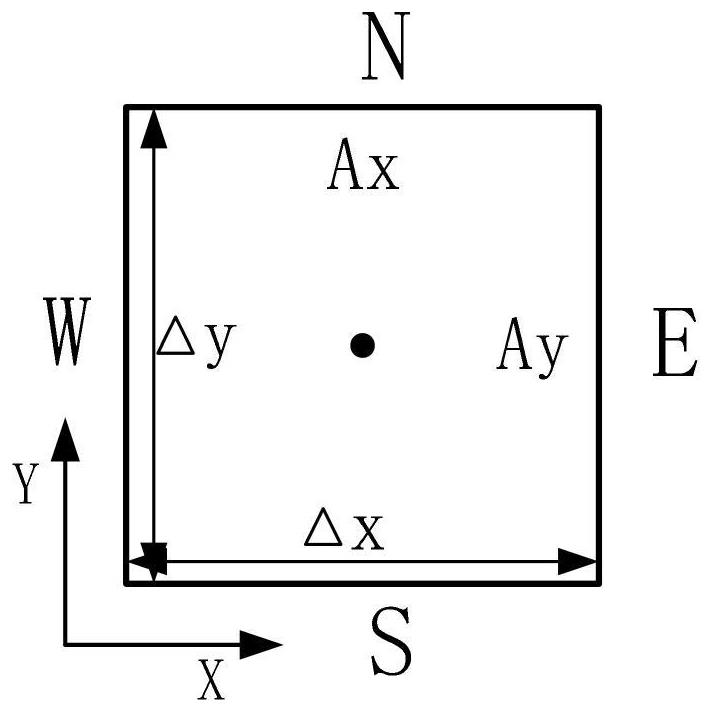

[0047] S5, based on the input conditions of step S1, establish a thermometer model of the hatch;

[0048] S6, establish a gas supply flow rate for each hot mesh in The thermal balance equation, based on the input conditions of step S1-S4, resulting in a gas flow rate m in .

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com