Vertical magnetic tunnel junction micromachining method based on shape anisotropy

An anisotropic and magnetic tunnel junction technology, applied in the field of micromachining of vertical magnetic tunnel junctions based on shape anisotropy, can solve the problems of lack of better preparation methods, reduction of coercive force and switching current, and weakening of demagnetization field. Achieve high yield and processing efficiency, reduce switching current and power consumption, and achieve high miniaturization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

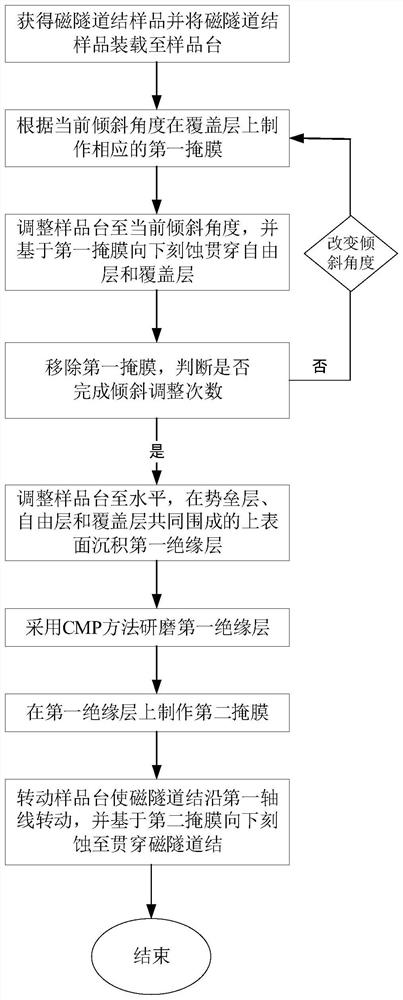

[0053] Such as Figure 3-7 As shown, a vertical magnetic tunnel junction micromachining method based on shape anisotropy. In this embodiment, the number of tilt adjustments of the sample stage 1 in step S2 is one time, and the free layer and the covering layer after etching are in the shape of oblique columns. . details as follows:

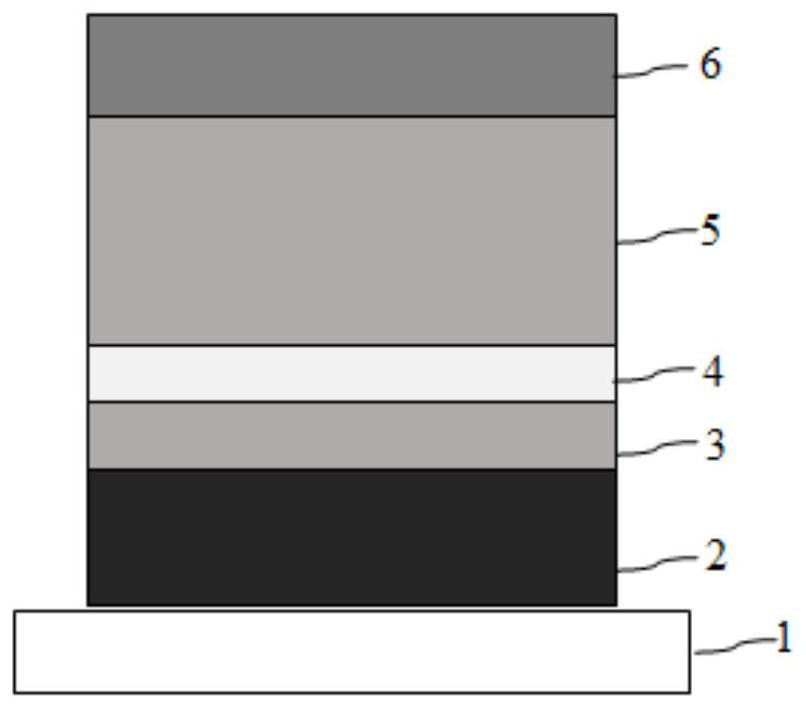

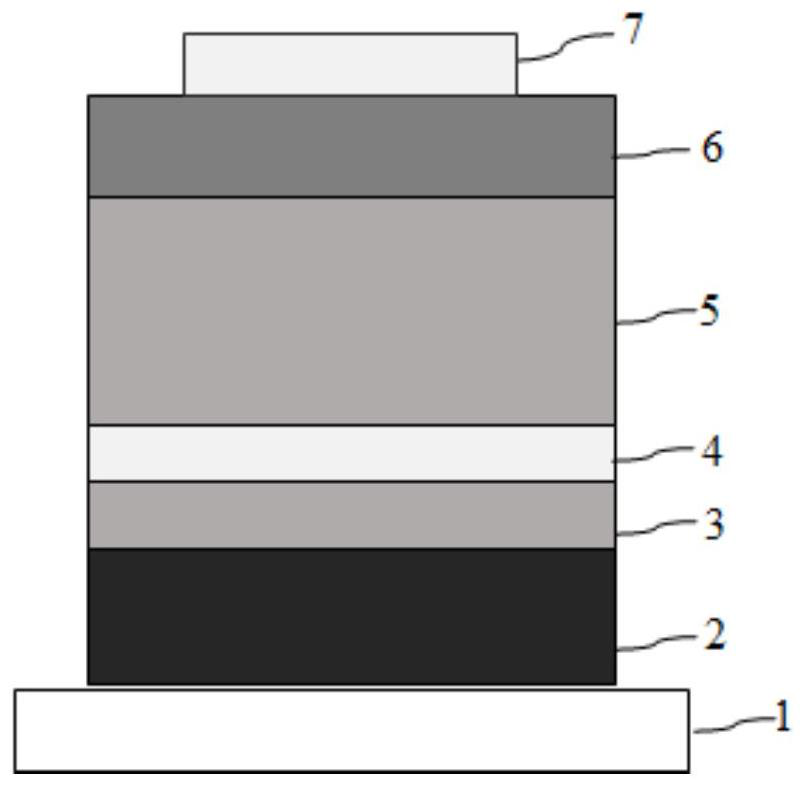

[0054] image 3 It is the process diagram of step S21 , the first mask 7 corresponding to the current inclination angle is fabricated on the cover layer 6 , and the sample stage 1 is at the horizontal position at this time.

[0055] Figure 4 It is the process diagram of step S22, the arrow in the figure indicates the etching direction (for example, the black dot indicates the ion implantation state), the white area surrounded by the dotted line frame is the etched area, and the sample stage 1 is adjusted to the current tilt angle θ 1 , stop when etching down to the free layer 5 and cover layer 6 based on the first mask 7 during processing, an...

Embodiment 2

[0063] Such as Figure 8 As shown, a vertical magnetic tunnel junction micromachining method based on shape anisotropy is based on Embodiment 1, the difference is that in this embodiment, the number of tilt adjustments of the sample stage is one, and the sample stage is also rotated around the second in step S22. The two axes rotate, the second axis is perpendicular to the horizontal plane, and the etched free layer and covering layer are in the shape of oblique columns.

[0064] specifically, Figure 8 It is the process diagram of step S22, the left vertical arrow in the figure indicates the etching direction (such as the black dot indicates the ion implantation state), the white area surrounded by the dotted line frame is the etched area, and the right arrow indicates the The direction of rotation around the second axis. The second axis is perpendicular to the horizontal plane and can be located at any position. It is preferable to make the sample stage 1 occupy a small spa...

Embodiment 3

[0066] Such as Figure 9-12 As shown, a vertical magnetic tunnel junction micromachining method based on shape anisotropy, in this embodiment, the tilt adjustment times of the sample stage is one time, and in step S22, the sample stage also rotates around the third axis, the third axis is The central axis of the first mask is perpendicular to the sample stage, and the etched free layer and cover layer are in the shape of an inverted cone. details as follows:

[0067] In step S21 (not shown in the figure), a first mask 7 corresponding to the current inclination angle is fabricated on the cover layer 6, and the sample stage 1 is at a horizontal position at this time.

[0068] Figure 9 It is the process diagram of step S22, the vertical arrow in the figure indicates the etching direction, the white area surrounded by the dotted line frame is the etched area, and the sample stage 1 is adjusted to the current inclination angle θ 1 , rotate the sample stage 1 during processing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com