Multifunctional metal plate laser machine rack

A laser machine and multi-functional technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of unfavorable cleaning, fixation of special-shaped objects, and influence on cutting effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

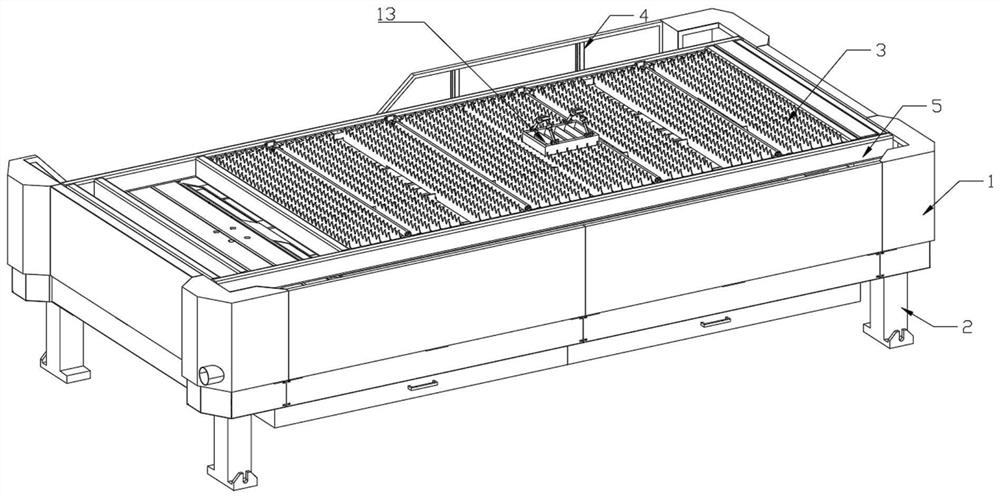

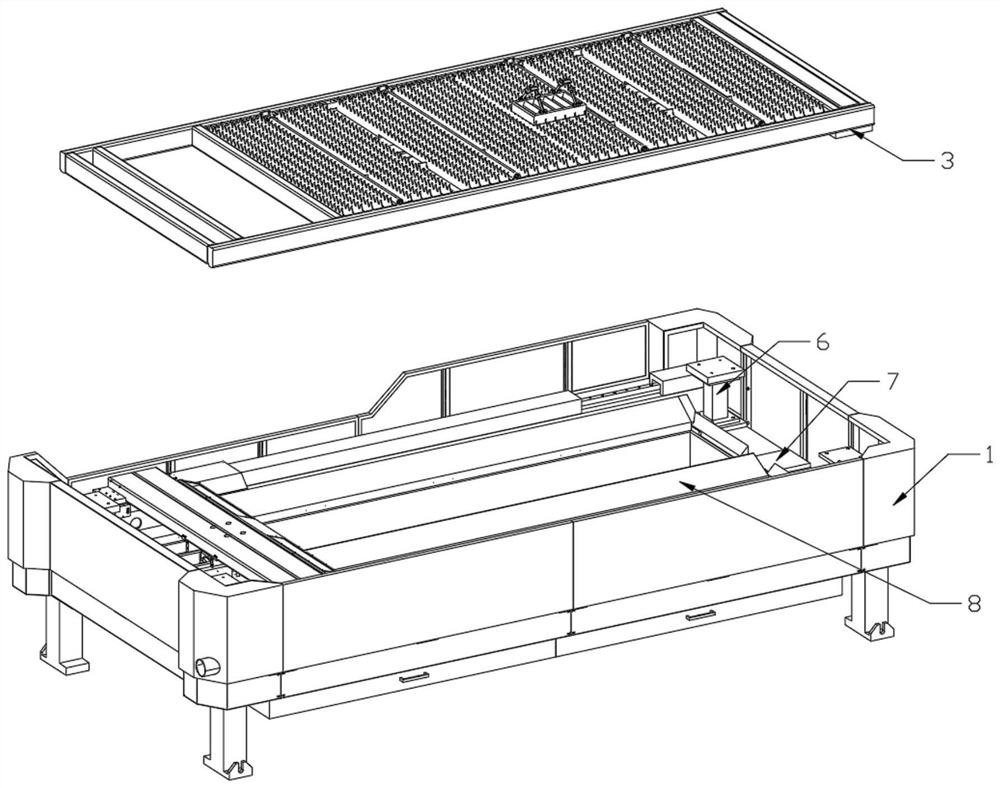

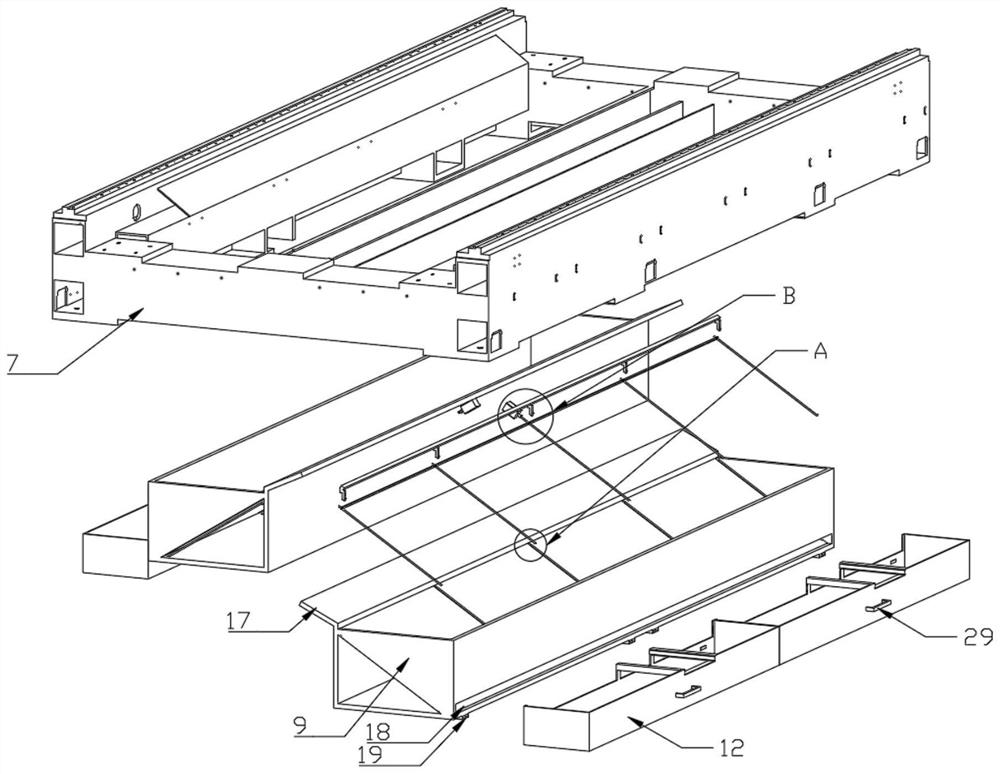

[0030] like Figure 1 - Figure 9 As shown, a multifunctional sheet metal laser frame provided by the present invention includes a frame 1, and a support leg 2 is provided on the bottom of the frame 1, respectively, and the inner wall body of the frame 1 is provided with a support frame. 7, the support frame 7 is provided with a support post 6, respectively, and a support column 6 is provided on the top wall of the support column 6, and a protective bar is also provided on the rear end of the rack 1. 1 The front end and the rear end wall are also provided with a rail 5, and the front end of the support frame 7 and the rear end wall are also provided with the cleaning mechanism 8, and the cleaning mechanism 8 includes a chip box 9, a screw 10, a scraper 11. A support mechanism 13 is further provided on the top of the bracket 3, and the support mechanism 13 includes a fixed stage 14, the mount 15 and the support rod 16.

Embodiment 2

[0032] The two chip chip 9 sides are fixed to one end wall of the support frame 7, respectively, and the two chip chopper 9 is fixedly coupled, and the chip box 9 is below the other side. There is also a divissing port 18 in the wall, and a plurality of fixed blocks 19 are fixedly mounted on both sides of the front end of the chip chopper 9, and there are several slide ports 20 in the bottom wall in the chip box 9, respectively. The bottom portion of the chipboard 9 is also fixed to the corresponding slide 20 on both sides of the wall, respectively, and the cleaning mechanism 8 also includes a motor 22 fixedly mounted on the central position wall of the guide plate 17 bottom. The motor 22 is electrically connected to the controller in the rack 1, and the walls of the screw 10 are each inserted into a fixed bearing mounted on one side wall of the chip chip size 9, and the solenoid of the screw 10 through the chuff The bearing of the side wall of the box 9 extends to the exterior of...

Embodiment 3

[0034]A plurality of card slots 30 are opened in the bottom wall of the fixed stage 14, and the fixing table 14 is mounted on the carriage 3 by the card groove 30, and several first restricted grooves 31 are also opened in the outer wall of the fixed stage 14. The mounting seat 15 bottom wall is fixedly mounted, and the second restrictive block 32 is inserted into the corresponding first-position slot 31, and the second limit block 32 has magnetic, mount 15. A fixed shaft 33 is formed in the two-side wall, and the support rod 16 is fixedly mounted on the bottom wall body, and the fixed shaft 34 is fixed in the corresponding hole 33, and the fixed shaft 34 side wall body is formed. A stopper 35 is also fixed, and a knob block 36 is further provided on the other side of the fixed shaft 34, and the second screw hole 37 is opened in the woven block 36, and the knob block 36 is rotated into the second screw hole 37. A fixing seat 38 is attached to the top wall of the support rod 16, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com